Splice welding locating device for front frame of loading machine

A positioning device and front frame technology, which is applied in the field of workpiece welding, can solve problems such as deviation and displacement size, and achieve the effects of reliable positioning, improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments provided by the present invention are described in further detail in conjunction with the accompanying drawings:

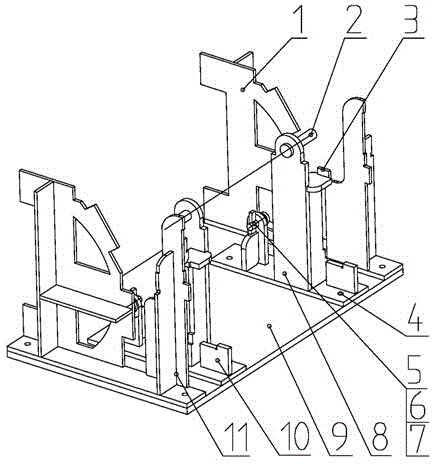

[0012] A positioning device for tailor welding of a front frame of a loader, comprising a base 9 on which a left outer positioning frame 1 , a left inner positioning frame 8 , a right inner positioning frame 10 and a right outer positioning frame 11 are provided.

[0013] Preferably, it also includes a long pin 2 , a movable spacer 3 , a cylindrical pin with internal thread 4 , a positioning pin 5 , a wedge 6 and a circular spacer 7 .

[0014] The invention adopts the positioning principle of the positioning shaft and the positioning surface to ensure the accuracy of the position of the workpiece during tailor welding, and the positioning of each size is guaranteed, reducing the use of measuring tools, using a pneumatic system, reducing labor intensity, providing reliable positioning, and improving product quality. And production efficiency, thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com