Closet with plate cover including built-in atomizing and spraying system

A technology of spraying system and toilet, applied in the field of sanitary equipment, can solve the problems of easily spreading bacteria or diseases, micro-bacteria residues in dirt, monotonous maintenance and nursing methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

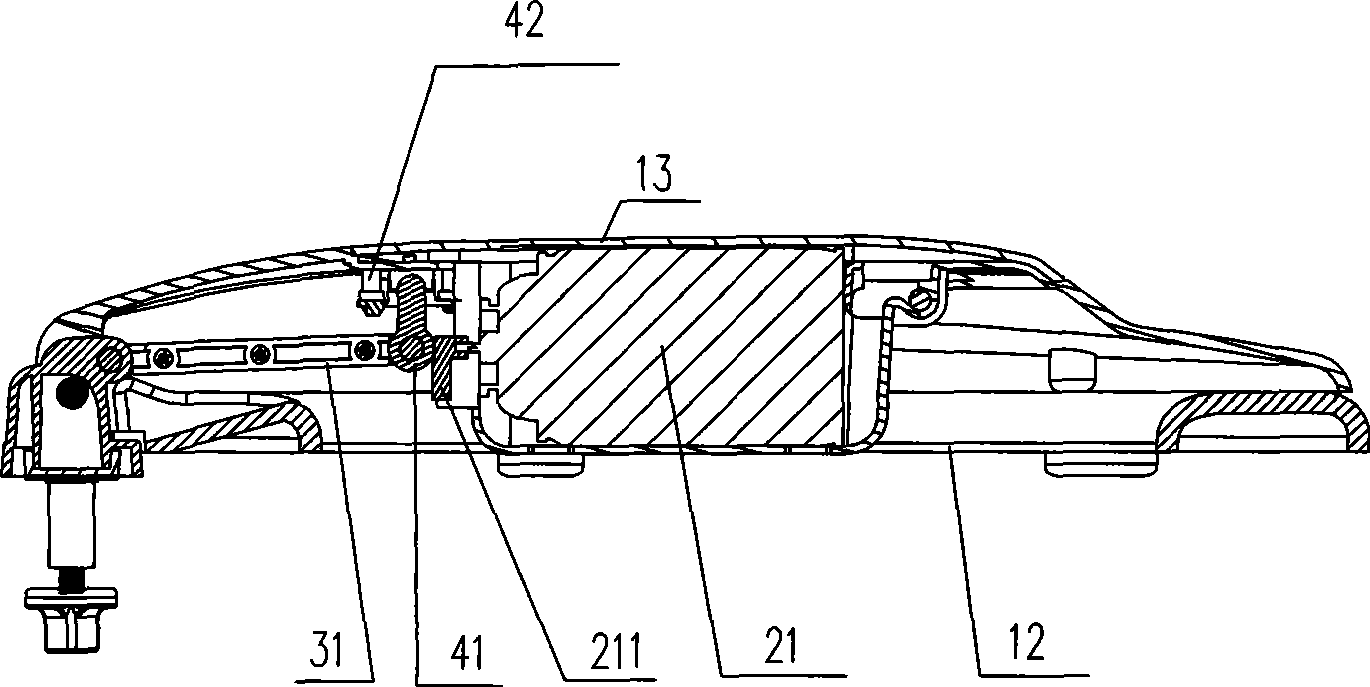

[0028] Such as figure 1 , figure 2 , image 3 , Figure 10 As shown, a toilet with a built-in spray system cover is provided with a toilet cover assembly on the toilet main body 132, and the toilet cover assembly includes a fixed base 11 fixed on the toilet main body 132 , the seat ring 12 and the toilet cover 13 coaxially arranged on the fixed base 11, the toilet cover 13 is provided with a recessed position 22 which is basically the same shape as the aerosol tank 21, and the spray tank 21 is placed in the recessed position 22 Inside, the toilet cover 13 is provided with a top cover 25 covering the recessed position 22, the surface of the toilet cover 13 is provided with a slide rail 26 matching the outer edge of the top cover 25, and the outer edge of the top cover 25 is placed on the slide. In rail 26, like this just can keep the attractive in appearance of water closet, it is very simple and convenient to change aerosol tank 21. The back of the toilet cover 13 is provid...

Embodiment 2

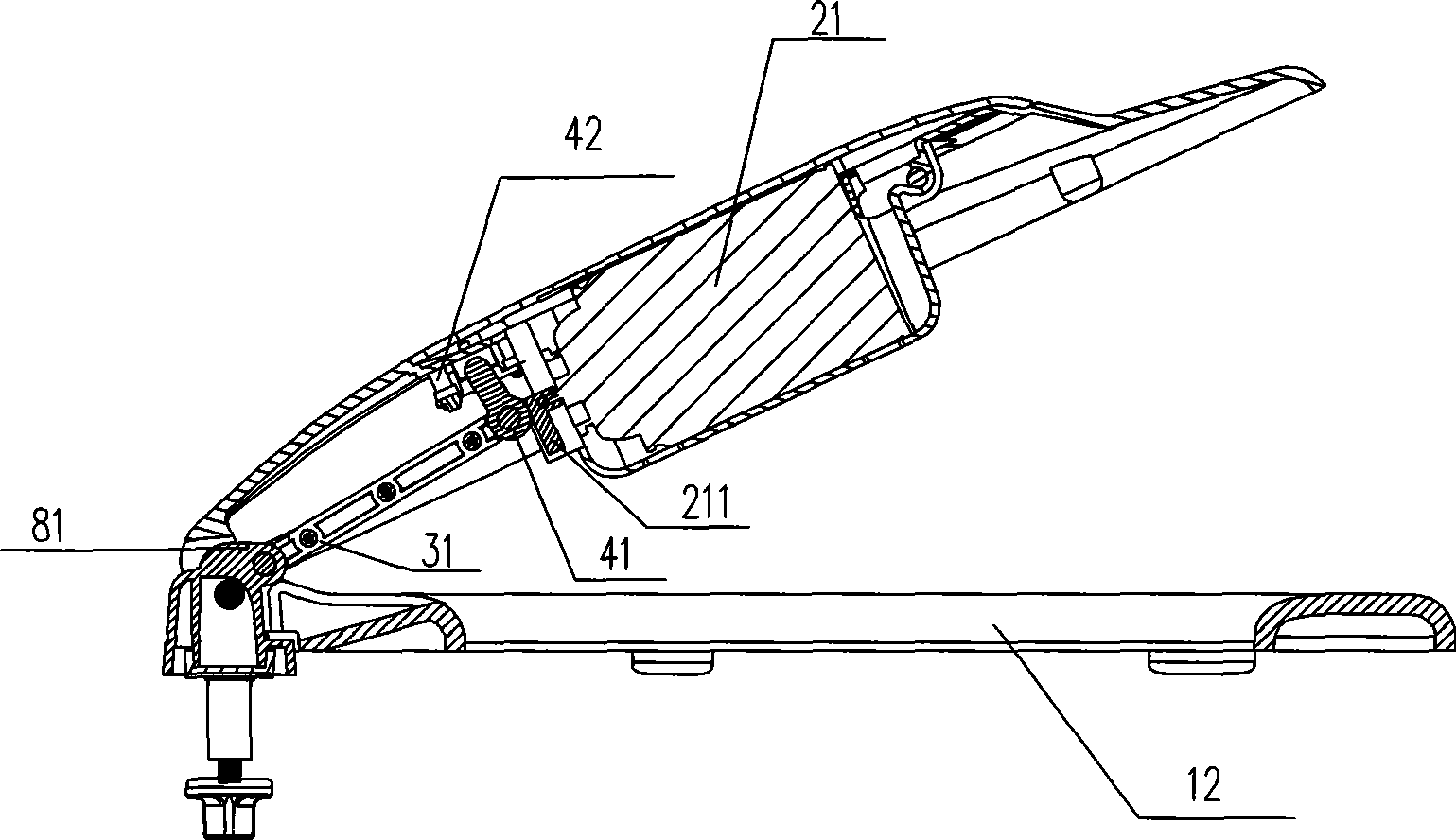

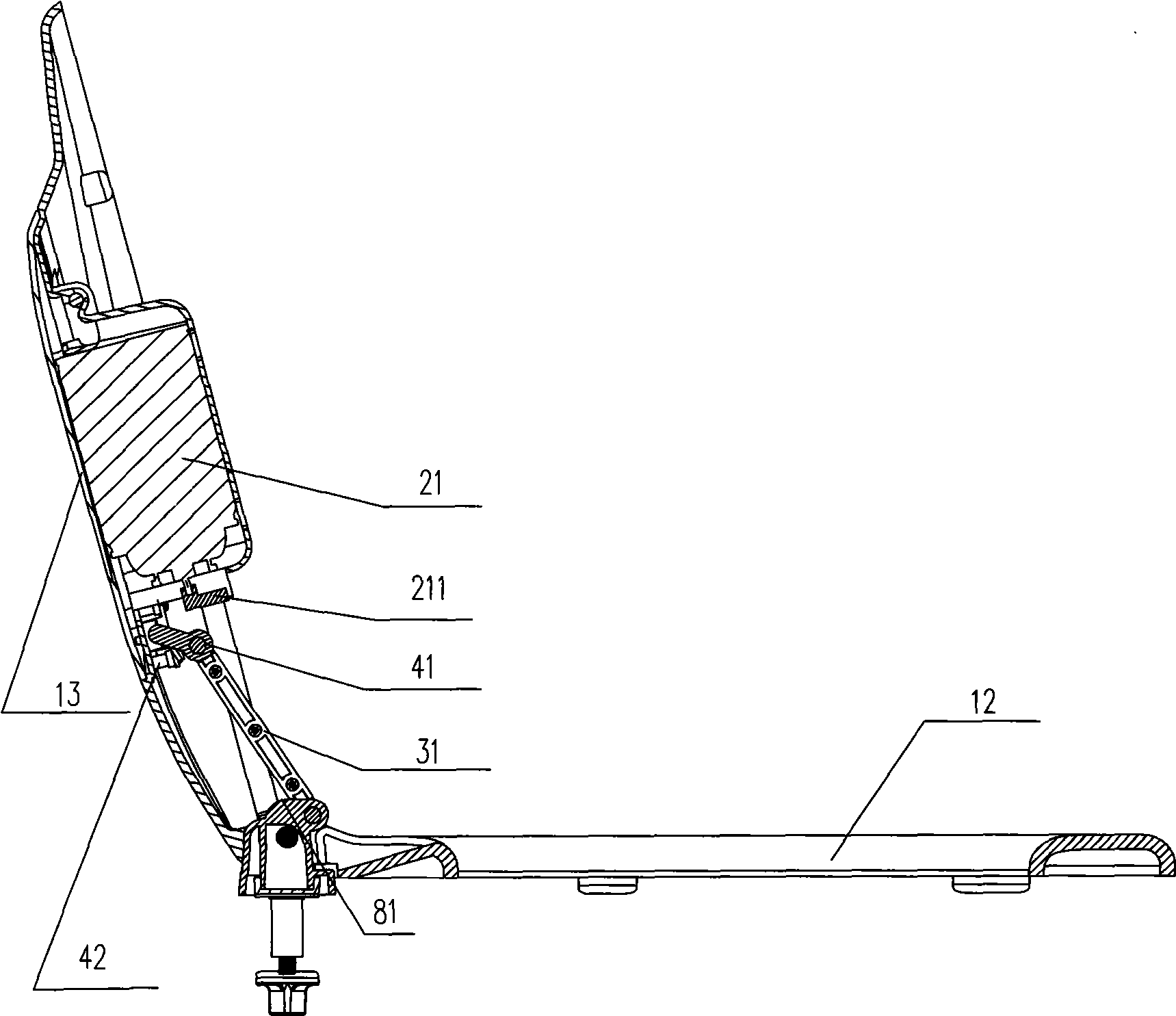

[0032] Such as Figure 4 , Figure 5 , Image 6 , Figure 10 As shown, the toilet of embodiment 2 is realized on the basis of embodiment 1 by substituting another push rod method. The push rod method of embodiment 2 is that both ends of the push rod 31 are connected with the toilet plate cover 13 by the lever 41 Hinged, this push rod 31, lever 41, toilet plate cover 13 are a quadrilateral truss structure equally. The fixed base 11 is provided with a cam 84. When the toilet cover 13 is opened to an angle of 25° with the toilet main body 132, the end of the push rod 31 is in close contact with the top of the cam 84 and gradually follows the opening of the toilet cover 13. And away from the cam 84, when the toilet plate cover 13 is opened, the push rod 31 is moved along the cam 84 to produce a stroke difference of 3 mm, that is, the effect of pushing the push rod 31 to trigger the nozzle 211 is reached.

Embodiment 3

[0034] Such as Figure 7 , Figure 10 As shown, embodiment 3 is realized with another trigger mechanism on the basis of retaining the fixed structure of the aerosol tank of embodiment 1. The trigger mechanism of embodiment 3 includes an eccentric wheel 51 arranged on the fixed base 11, and the toilet plate The back of the cover 13 is provided with two lugs 61 with shaft holes and is provided with a push rod 31 that can be pressed to the spray tank nozzle 211 and passes through the two lugs 61. The push rod 31 between the two lugs 61 is provided with two Protrusions 62, springs 7 are arranged between the protrusions 62 and the respective closer protruding pieces 61; when the toilet cover 13 is opened, the push rod 31 is pushed by the eccentric wheel 51 so that the push rod 31 is pressed against the nozzle 211 to spray out Disinfecting fragrance spray; when the toilet cover 13 is closed, the push rod 31 is returned to the initial state through the interaction force between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com