Protection assembly

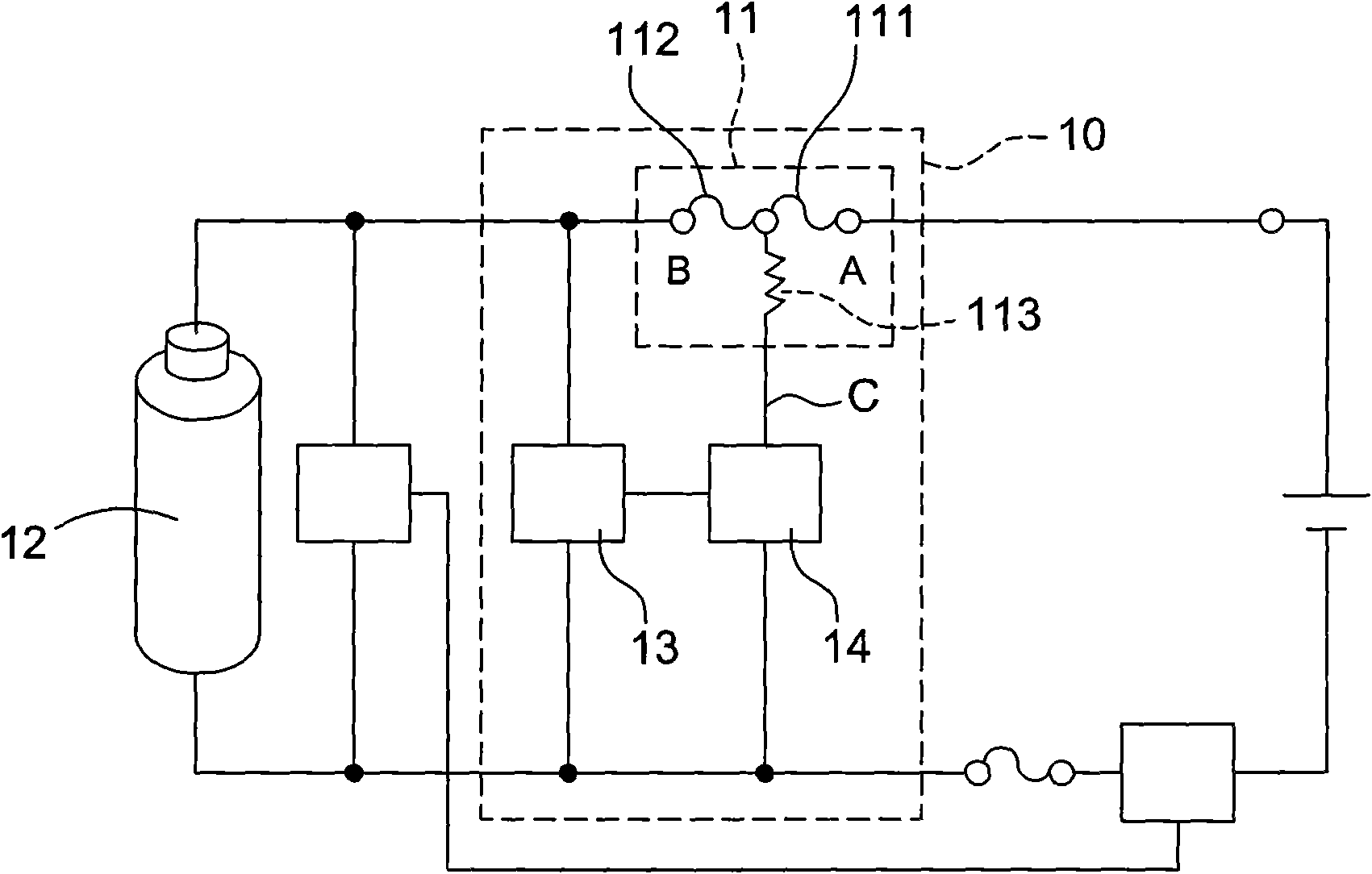

A component and substrate technology, applied in the field of protection components, can solve problems such as failure of the protection component 20, failure to protect charging devices or batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

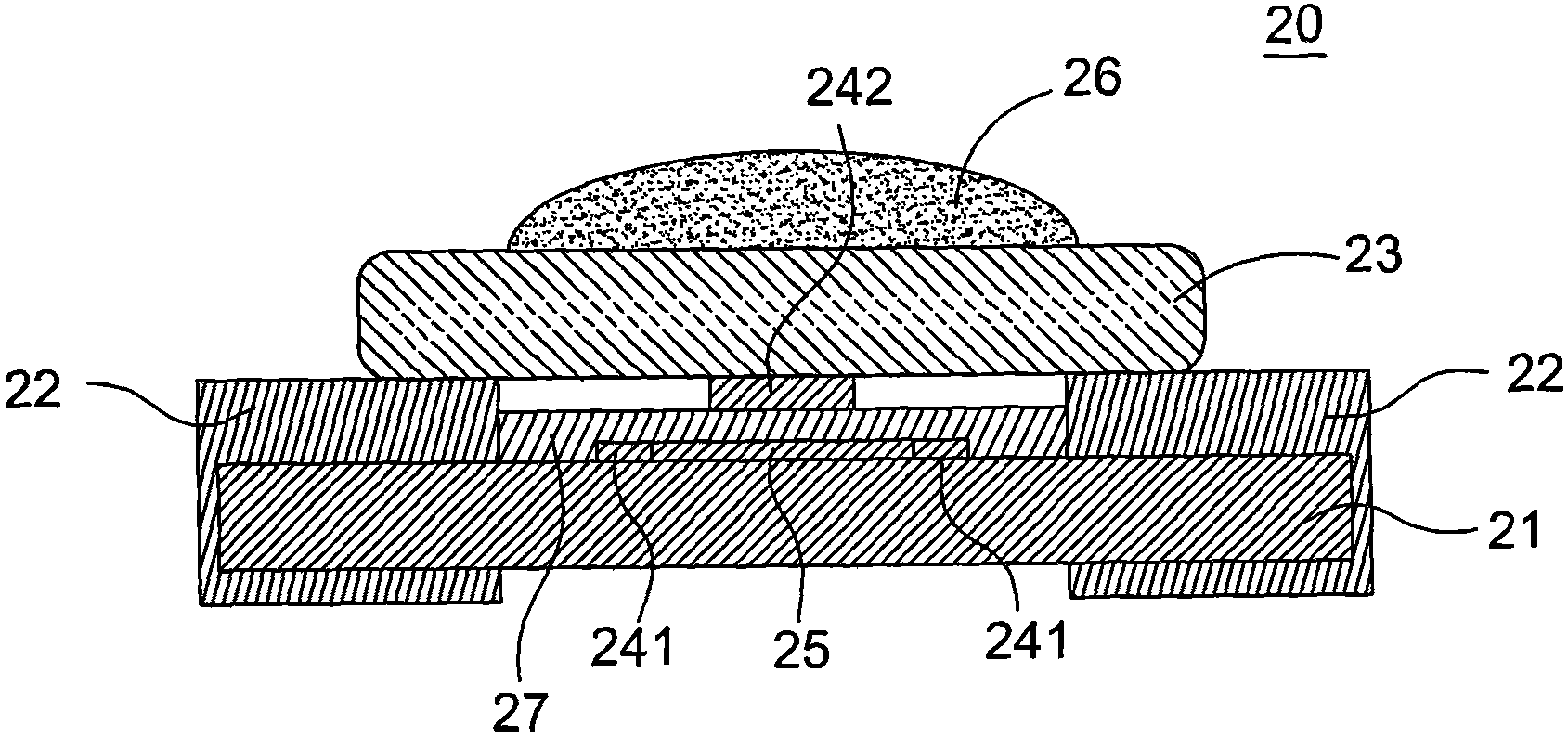

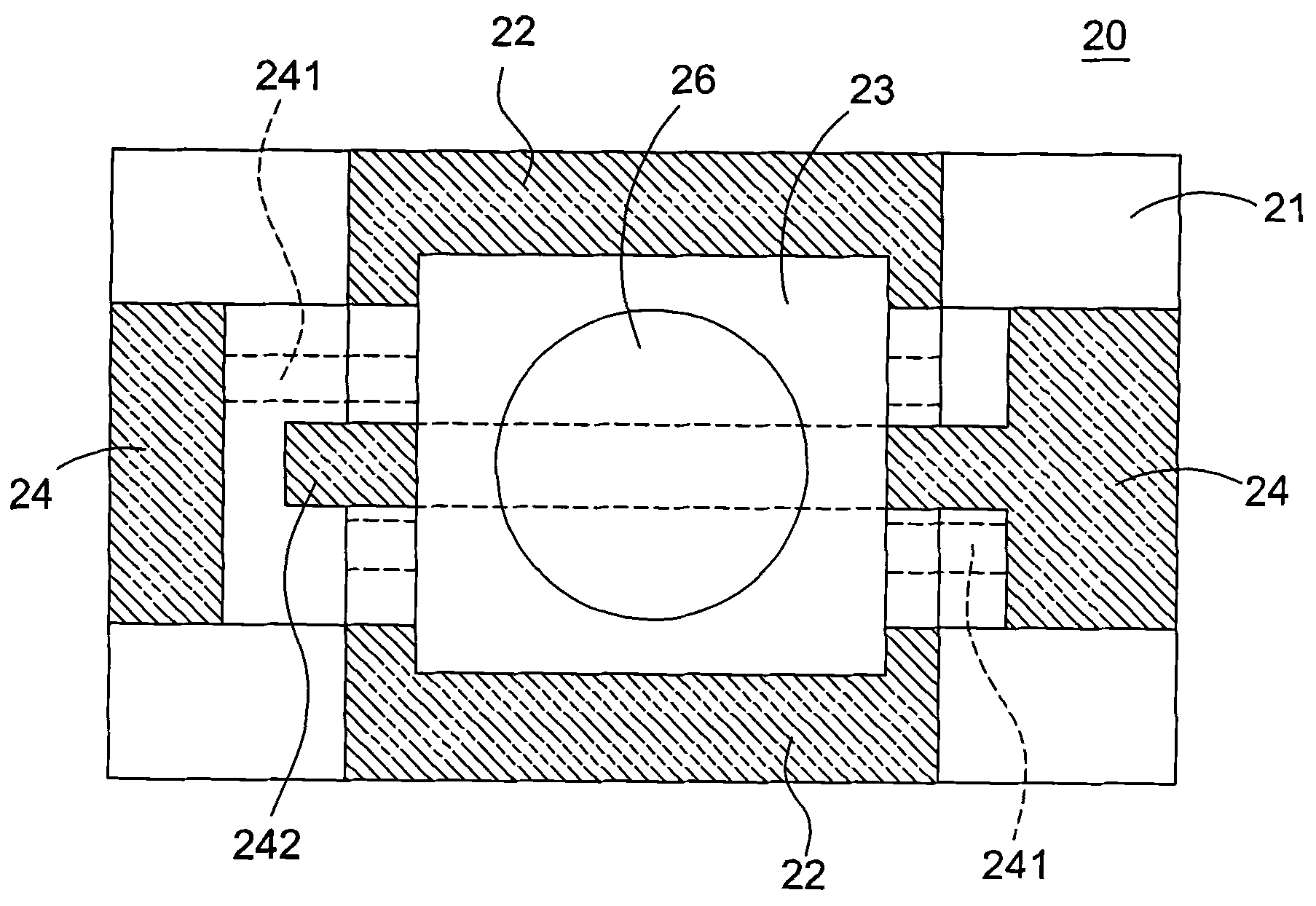

[0028] like Figure 4 Shown is a cross-sectional view of the protection assembly 30 of the first preferred embodiment of the present invention. In this embodiment, the protection component 30 can be a surface mount electronic component, which can be mounted on a circuit board through a reflow process. The protection component 30 includes a substrate 31 at its core. The substrate 31 is made of insulating material and is roughly rectangular. Specifically, suitable materials for the substrate 31 include inorganic materials such as ceramics (such as alumina), zirconia, silicon nitride, aluminum nitride, and boron nitride, or plastics, glass epoxy resin, and the like. For practical applications, inorganic materials are especially preferred.

[0029] Above the substrate 31, the protection component 30 includes two first electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com