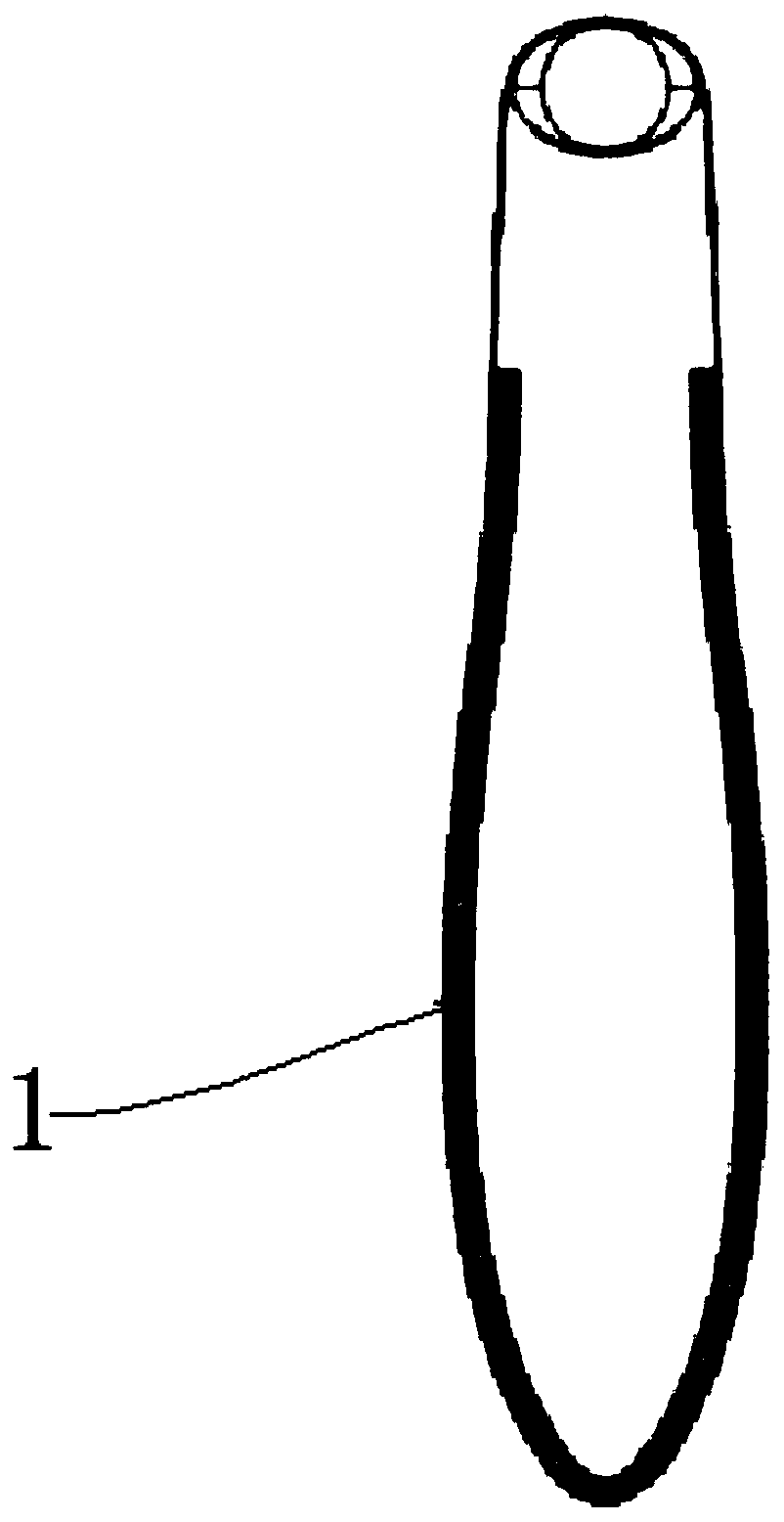

Fabrication method of composite nasal bridge prosthesis with surface micropores

A surface microporous, composite technology, applied in prostheses, nose implants, medical science, etc., can solve the problems of combination, prosthesis displacement, and poor treatment effect of nose bridge prosthesis, so as to improve the treatment effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A method for manufacturing a composite nose bridge prosthesis with surface micropores, comprising the following steps:

[0025] Step 1: Sand blast the mold surface of the silicone rubber nose bridge prosthesis to form a certain roughness of 1-3 μm;

[0026] Step 2: Put the silicone rubber into the mold cavity for vulcanization, take out the product after vulcanization, and trim the excess residual edges to make a silicone rubber nose bridge prosthesis with a certain roughness on the surface of the back of the nose, with a roughness of 1-3 μm ;

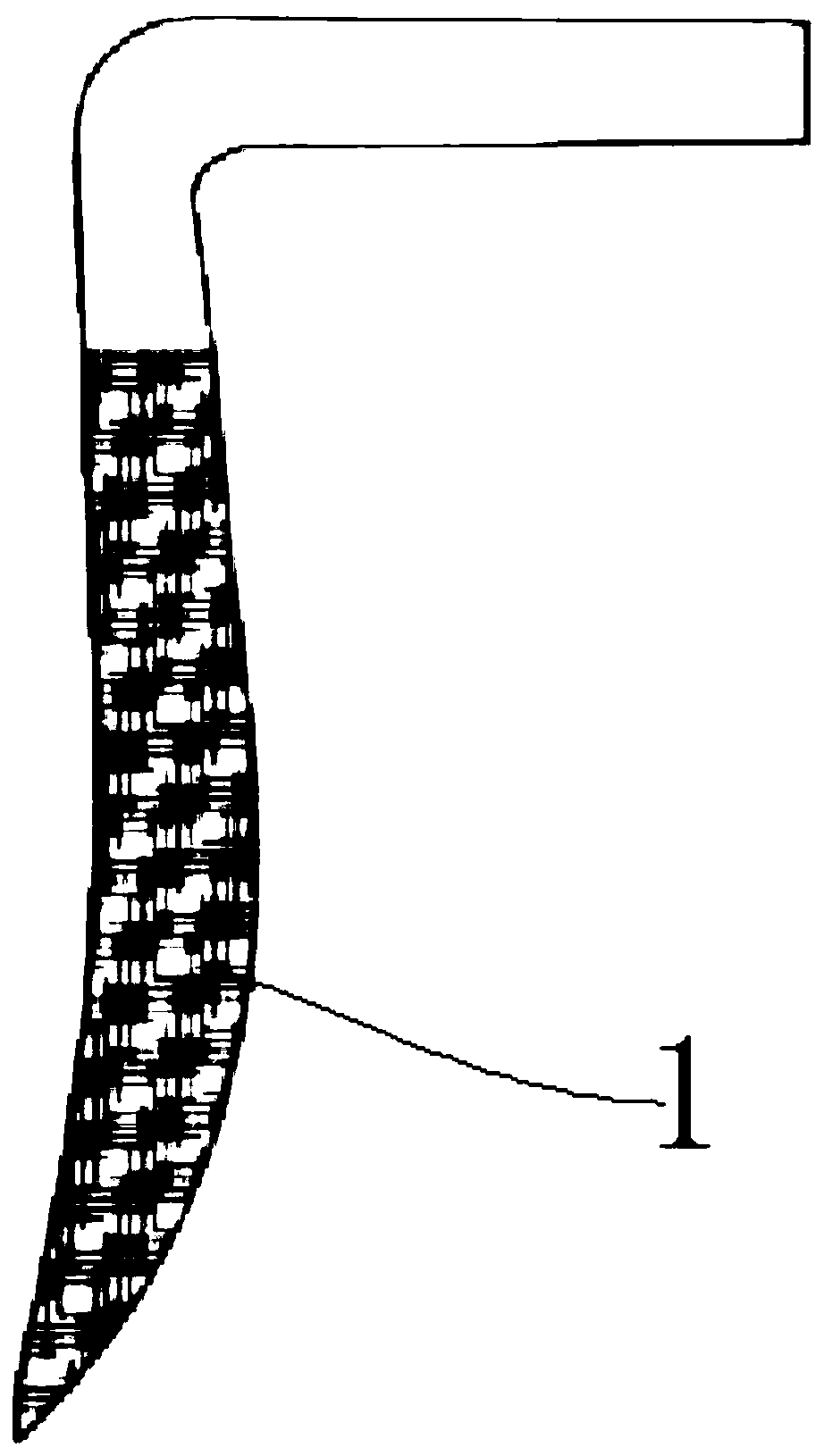

[0027] Step 3: Cut the expanded polytetrafluoroethylene strip with scissors according to the size and shape of the nasal dorsal surface of the silicone rubber nose bridge prosthesis;

[0028] Step 4: Dissolve medical semi-solid silicone rubber in petroleum ether solvent to fully dissolve it;

[0029] Step 5: Apply the liquid silicone rubber with a certain viscosity prepared in step 4 evenly on the upper surface of the lower pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com