Folding type planar three-phase open transformer core

A transformer iron core, folded technology, applied in the field of transformers, can solve the problems of reducing the quality of the transformer, affecting the performance of the iron core, loosening, etc., to achieve the effect of improving mechanical strength, high production efficiency, and solving easy loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the content of the invention clearly understandable, the present invention will be further described below in conjunction with the drawings and embodiments, but this does not constitute a limitation to the present invention.

[0025] specific implementation plan

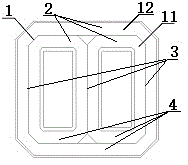

[0026] See ( figure 1 ), the present invention includes an iron core 1, an upper iron yoke 2 of the iron core, a lower iron yoke 4 of the iron core, and three core posts 3 of the iron core.

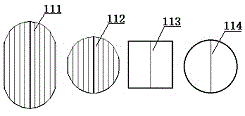

[0027] See ( figure 2 ) section is oblong polygon 111 , polygon inscribed in a circle, rectangle 113 , and circle (R-shaped) 114 .

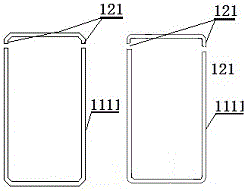

[0028] See ( image 3 ) ( Figure 4 ) ( Figure 5 ) ( Image 6 ) strip frame.

[0029] As an improvement of the technical solution, "a multi-purpose iron core manufacturing equipment" provided by the patent certificate No. 3472719 applied by me is adopted. It is characterized in that: the processed strip 1111 can be butted to have 8 135° or 12 Quasi-rectangular sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com