A drug-loaded nanofiber microsphere/hydrogel composite and its preparation method and application

A drug-loaded nanometer and hydrogel technology, which is applied in drug combination, drug delivery, and pharmaceutical formulations, can solve the problems of small hydrophobicity of PPO chain segments, high critical micelle concentration, and increased raw material usage, so as to solve the problem of migration Positioning and disintegration, good biosafety, and the effect of reducing the number of administrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

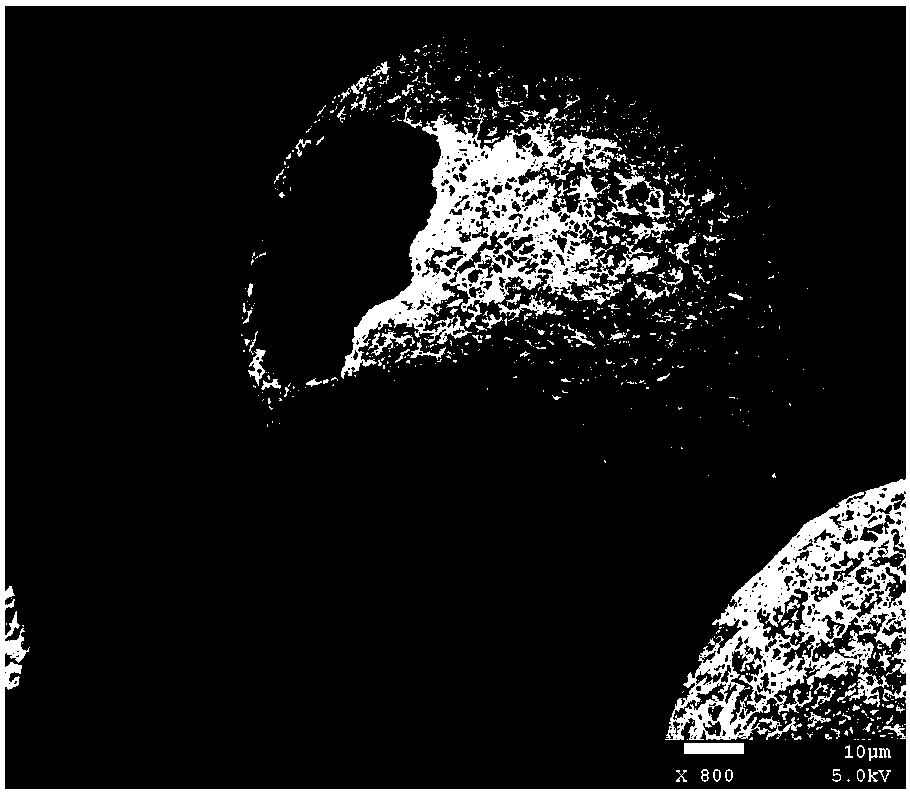

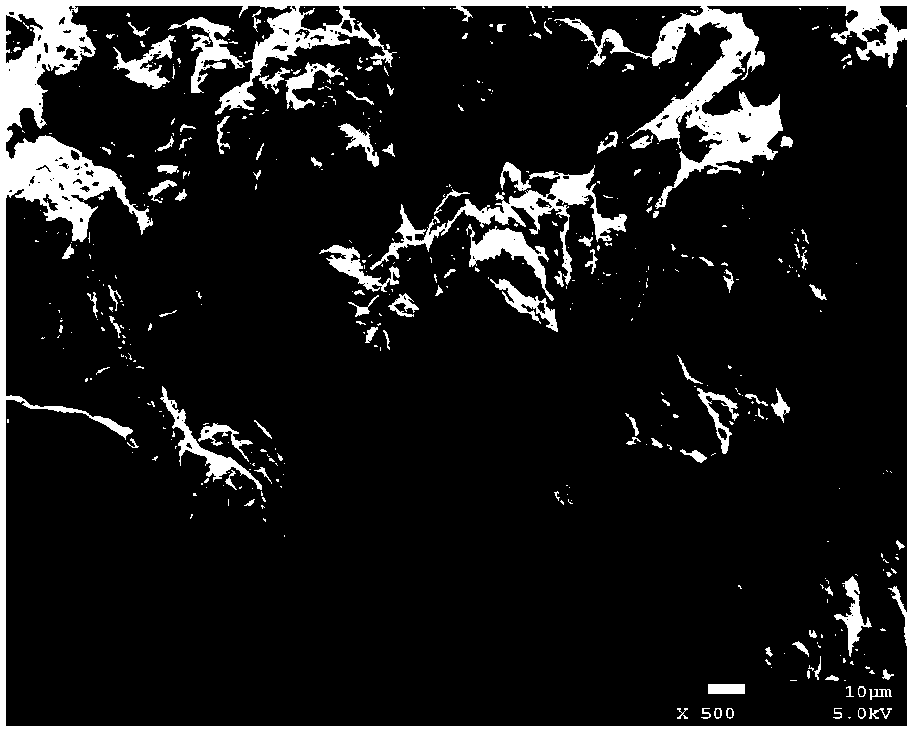

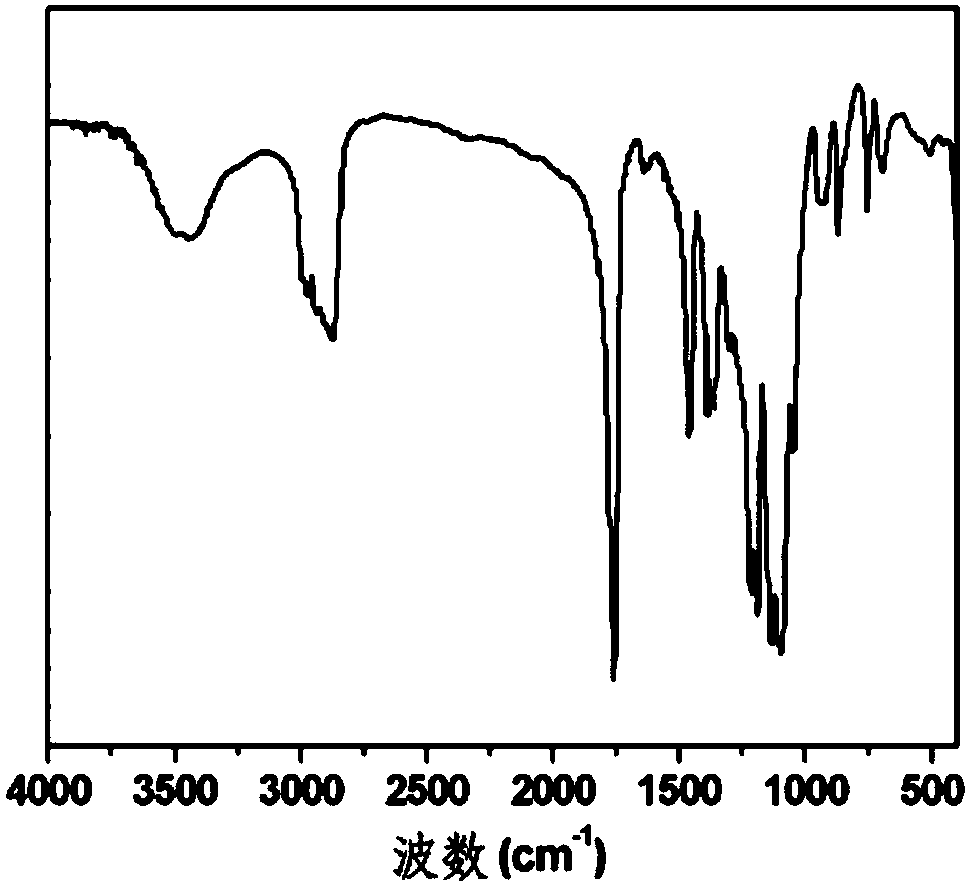

Embodiment 1

[0059] Under the protection of nitrogen flow, L-lactide, poloxamer F68 with a mass ratio of 2.57 and 0.3 wt% stannous octoate based on the total mass of L-lactide and poloxamer were heated to 180 °C and stirred React for 24 hours, cool to room temperature, then add dichloromethane to dissolve the reaction product, then put it into methanol 10 times the volume of dichloromethane to precipitate, filter, dissolve the white precipitate with dichloromethane and put it in dichloromethane Continue to precipitate, filter, and dry in diethyl ether of 10 times the volume of methyl chloride to obtain the theoretical molecular weight Mn a 3.0×10 4 Polylactic acid-poloxamer F68-polylactic acid multi-block polymer. Mn calculated by NMR b 2.85×10 4 , GPC results measured Mw c 4.23×10 4 , Mn c 3.02×10 4 .

Embodiment 2

[0061] Under the protection of nitrogen flow, L-lactide with a mass ratio of 0.786, poloxamer F68 and 0.3wt% stannous octoate based on the total mass of L-lactide and poloxamer were heated to 150°C and stirred React for 15 hours, cool to room temperature, then add dichloromethane to dissolve the reaction product, then put it into methanol 10 times the volume of dichloromethane to precipitate, filter, dissolve the white precipitate with dichloromethane and put it in dichloromethane Continue to precipitate, filter, and dry in diethyl ether of 10 times the volume of methyl chloride to obtain the theoretical molecular weight Mn a 1.5×10 4 Polylactic acid-poloxamer F68-polylactic acid multi-block polymer. Mn calculated by NMR b1.36×10 4 , GPC results measured Mw c 2.30×10 4 , Mn c 1.52×10 4 .

Embodiment 3

[0063] According to the above synthesis route, under the protection of nitrogen flow, L-lactide, poloxamer F68 with a mass ratio of 1.38 and 0.3wt% stannous octoate based on the total mass of poloxamer and L-lactide Heat to 140°C and stir for 20 hours, cool to room temperature, then add dichloromethane to dissolve the reaction product, then put it into methanol 10 times the volume of dichloromethane to precipitate, filter, and dissolve the white precipitate with dichloromethane After that, put it into diethyl ether of 10 times the volume of dichloromethane and continue to precipitate, filter, and dry to obtain the theoretical molecular weight Mn a 2.5×10 4 Polylactic acid-poloxamer F68-polylactic acid multi-block polymer. Mn calculated by NMR b 2.56×10 4 , GPC results measured Mw c is 3.74×10 4 , Mn c 2.38×10 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com