Treatment method for reducing pour point of natural ester insulating oil

A treatment method and insulating oil technology, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of lowering the ignition point of vegetable insulating oil and affecting the fireproof performance, and achieve the effects of ensuring the overall performance, improving the degree of uniform dispersion, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

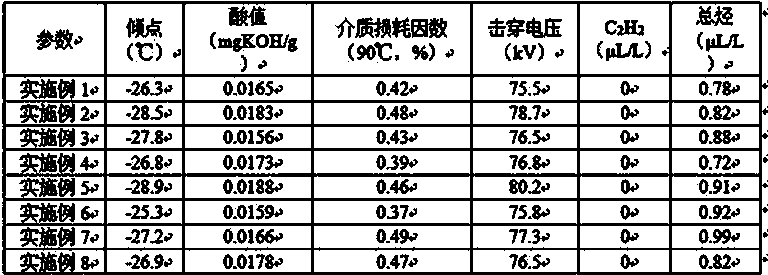

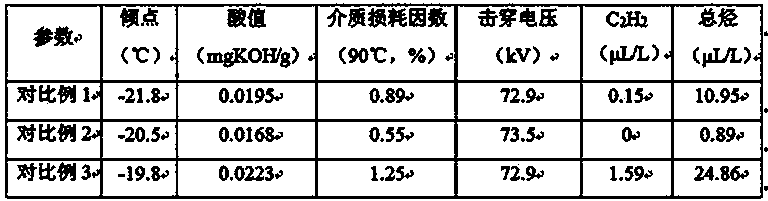

Examples

Embodiment 1

[0034] A processing method for reducing the pour point of natural ester insulating oil, comprising the following steps:

[0035] 1) Under the vacuum conditions of 60r / min and -0.096Mpa, the soybean insulating oil was heated to 65°C, and then the soybean insulating oil was subjected to short-term ultrasonic vibration treatment by means of "ultrasonic oscillation for 3 minutes and stop for 2 minutes". The ultrasonic power was 280W, and the ultrasonic Frequency 16kHz, ultrasonic treatment time 15min, continuous stirring 30min;

[0036] 2) Adjust the speed to 30r / min, vacuum cool the soybean insulating oil to 22°C, and keep stirring for 60min;

[0037] 3) Maintain the temperature difference between the cooling medium and the soybean insulating oil at 10°C, and cool the soybean insulating oil to 5°C at atmospheric pressure under the stirring condition of 5r / min for 10h;

[0038] 4) Keep the temperature difference between the cooling medium and the soybean insulating oil at 7°C, an...

Embodiment 2

[0042] A processing method for reducing the pour point of natural ester insulating oil, comprising the following steps:

[0043] 1) Under the vacuum conditions of 70r / min and -0.1Mpa, heat the rapeseed insulating oil to 70°C, and use the method of "ultrasonic oscillation for 3 minutes, stop for 3 minutes" to conduct short-term ultrasonic oscillation treatment on the soybean insulating oil. The ultrasonic power is 260W. Ultrasonic frequency 20kHz, ultrasonic treatment time 18min, continuous stirring 45min;

[0044] 2) Adjust the speed to 25r / min, vacuum-cool the rapeseed insulating oil to 20°C, and keep stirring for 70min;

[0045] 3) Maintain the temperature difference between the cooling medium and the rapeseed insulating oil at 8°C, and cool the rapeseed insulating oil to 4°C at atmospheric pressure under the stirring condition of 8r / min for 8 hours;

[0046] 4) Keep the temperature difference between the cooling medium and the rapeseed insulating oil at 5°C, and cool the r...

Embodiment 3

[0050] A processing method for reducing the pour point of natural ester insulating oil, comprising the following steps:

[0051] 1) Under the vacuum conditions of 65r / min and -0.098Mpa, heat the camellia seed insulating oil to 68°C, and then use the method of "ultrasonic oscillation for 2.5min, stop for 2.5min" to conduct short-term ultrasonic oscillation treatment on soybean insulating oil. 300W, ultrasonic frequency 16kHz, ultrasonic treatment time 20min; continuous stirring for 40min;

[0052] 2) Adjust the speed to 25r / min, vacuum-cool the camellia seed insulating oil to 18°C, and keep stirring for 65min;

[0053] 3) Maintain the temperature difference between the cooling medium and the camellia seed insulating oil at 10°C, and cool the camellia seed insulating oil to 3°C at normal pressure under the stirring condition of 6r / min for 10h;

[0054] 4) Keep the temperature difference between the cooling medium and the camellia seed insulating oil at 5°C, and cool the camelli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com