A low pour point environment-friendly transformer oil with good oxidation resistance

A technology of anti-oxidation performance and transformer oil, which is applied in the petroleum industry, fat oil/fat refining, lubricating composition, etc., can solve the problems of complicated preparation methods, unsuitable for large-scale production, and long cycle, etc., to improve the anti-oxidation performance , improve the structure and characteristics, improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

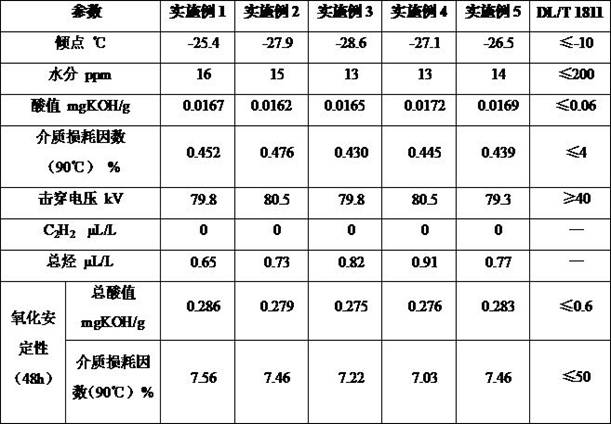

[0031] A low pour point environment-friendly transformer oil with good anti-oxidation performance is composed of refined soybean insulating oil, polymethacrylate accounting for 1.0% of oil weight, 4,4-methylene (2.6-dimethacrylate) accounting for 0.5% of oil weight tert-butylphenol), the specific performance parameters are shown in Table 1.

[0032] The preparation process of the low pour point environment-friendly transformer oil with good oxidation resistance includes the following steps:

[0033] 1) Heat the refined soybean insulating oil to 72°C under 50r / min and -0.1Mpa vacuum conditions, add diatomaceous earth with an oil weight of 0.4%, and use the cycle mode of "ultrasonic dispersion for 2 minutes, stop for 3 minutes" for short-term ultrasonic dispersion Treatment, ultrasonic power 100W, ultrasonic frequency 24kHz, ultrasonic treatment time 10min, continuous stirring 30min, to obtain a mixture;

[0034] 2) Cool the mixture to 20°C at a cooling rate of 10°C / h under the...

Embodiment 2

[0039] A low pour point environment-friendly transformer oil with good oxidation resistance is composed of refined rapeseed insulating oil, polymethacrylate accounting for 1.2% of oil weight, 4,4-methylene (2.6- Di-tert-butylphenol) additive composition, specific performance parameters are shown in Table 1.

[0040] The preparation process of the low pour point environment-friendly transformer oil with good oxidation resistance includes the following steps:

[0041] 1) Heat the refined rapeseed insulating oil to 70°C under 45r / min and -0.098Mpa vacuum conditions, add diatomaceous earth with an oil weight of 0.5%, and use the cycle mode of "ultrasonic dispersion for 2 minutes, stop for 3 minutes" for short-term ultrasonic Dispersion treatment, ultrasonic power 120W, ultrasonic frequency 20kHz, ultrasonic treatment time 10min, continuous stirring 40min, to obtain a mixture;

[0042] 2) Cool the mixture to 22°C at a cooling rate of 8°C / h under the stirring condition of 25r / min. ...

Embodiment 3

[0047] A low pour point environment-friendly transformer oil with good oxidation resistance is composed of refined rapeseed insulating oil, polymethacrylate accounting for 0.5% of oil weight, alcohol ester type maleic anhydride-vinyl acetate accounting for 0.8% of oil weight - Styrene polymer, tert-butylhydroquinone 0.35% by weight of oil, 4,4-methylene (2.6-di-tert-butylphenol) 0.25% by weight of oil, sulfur 0.4% by weight of oil The additive composition of substituting dilauryl dipropionate, the specific performance parameters are shown in Table 1.

[0048] The preparation process of the low pour point environment-friendly transformer oil with good oxidation resistance includes the following steps:

[0049] 1) Heat the refined rapeseed insulating oil to 70°C under 40r / min and -0.096Mpa vacuum conditions, add diatomaceous earth with an oil weight of 0.35%, and use the cycle mode of "ultrasonic dispersion for 2 minutes, stop for 3 minutes" for short-term ultrasonic Dispersion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com