Pretreatment method of guanine wastewater

A guanine and pretreatment technology, applied in the field of guanine wastewater pretreatment, can solve the problems of high concentration of organic pollutants, refractory degradation, effluent chemical oxygen demand and total nitrogen compliance, etc., so as to improve the degradation effect and save costs. , Improve the effect of BOD/COD ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

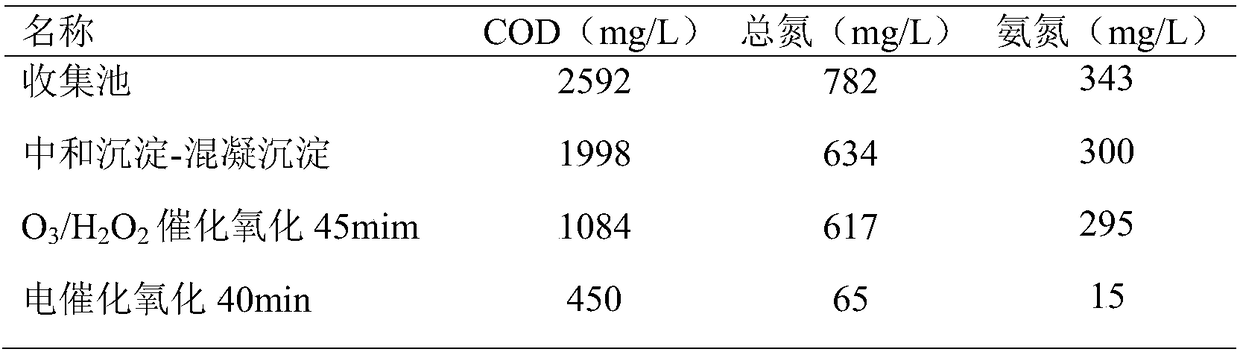

Embodiment 1

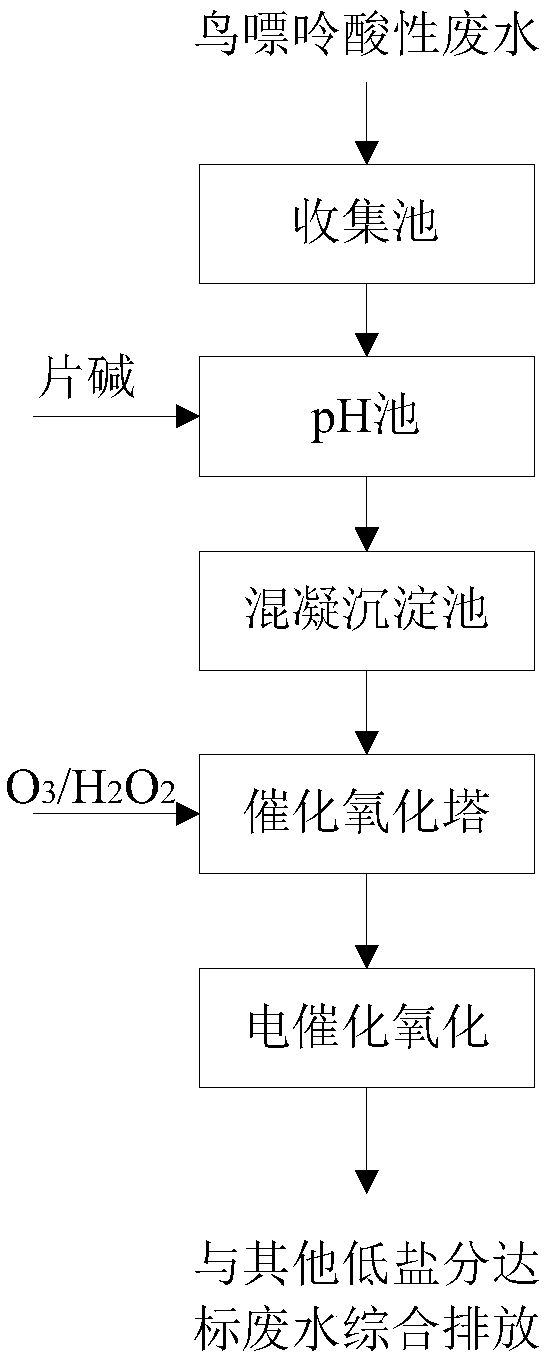

[0045] The specific steps in this embodiment are as follows:

[0046] The first step: pump the guanine wastewater into the collection tank, enter the pH adjustment tank after homogenization and uniformity, add sodium hydroxide (flake caustic soda), adjust the pH to 7 for neutralization and precipitation, and obtain the first-level effluent;

[0047] The second step: the first-level effluent in the first step enters the coagulation sedimentation tank for coagulation and sedimentation. PAC is a flocculant, and the dosage is 100mg / L; at the same time, PAM is added as a coagulant, and the dosage is 7mg / L. After the coagulation and sedimentation is over, the supernatant is taken to obtain the secondary effluent;

[0048] The third step: pump the secondary effluent in the second step into the catalytic oxidation tower, and add H in an amount of 0.2% of the volume of wastewater 2 O 2 Solution (mass fraction of 30%), add 500mg / L ozone, perform O 3 / H 2 O 2 Catalytic oxidation, the reaction ...

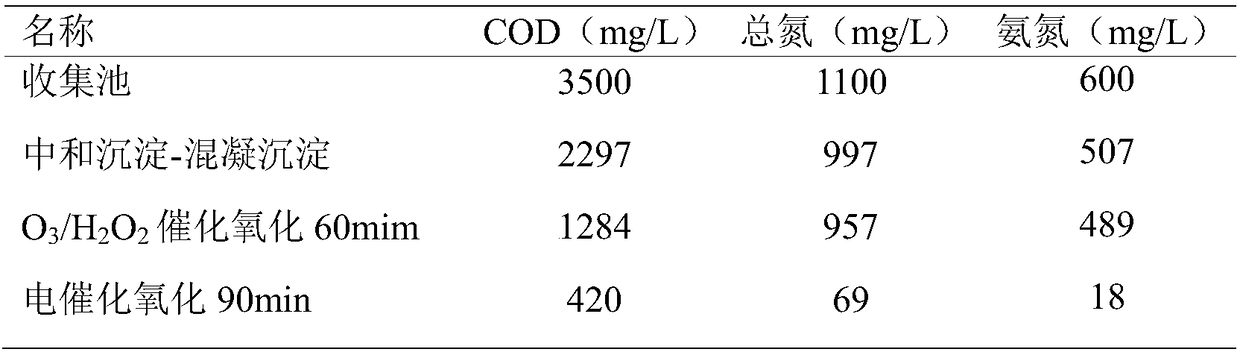

Embodiment 2

[0056] The specific steps in this embodiment are as follows:

[0057] The first step: pump the guanine wastewater into the collection tank, enter the pH adjustment tank after homogenization, add sodium hydroxide (flake caustic soda), adjust the pH to 5 for neutralization and precipitation, and obtain the first-level effluent;

[0058] The second step: the first-level effluent in the first step enters the coagulation sedimentation tank for coagulation and precipitation, PAS is a flocculant, and the dosage is 300mg / L; at the same time, PAM is added as a coagulant, and the dosage is 5mg / L. After the coagulation and sedimentation is over, the supernatant is taken to obtain the secondary effluent;

[0059] The third step: Pump the secondary effluent in the second step into the catalytic oxidation tower, and add H in an amount of 0.5% of the waste water volume 2 O 2 Solution (mass fraction of 30%), add 300mg / L ozone, perform O 3 / H 2 O 2 Catalytic oxidation, the reaction time is controlle...

Embodiment 3

[0067] The specific steps in this embodiment are as follows:

[0068] The first step: pump the guanine wastewater into the collection tank, enter the pH adjustment tank after homogenization, add sodium hydroxide (flake caustic soda), adjust the pH to 6 for neutralization and precipitation, and obtain the first-level effluent;

[0069] The second step: the first-stage effluent in the first step enters the coagulation sedimentation tank for coagulation and sedimentation, PAFC is a flocculant, and the dosage is 500mg / L; at the same time, PAM is added as a coagulant, and the dosage is 10mg / L. After the coagulation and sedimentation is over, the supernatant is taken to obtain the secondary effluent;

[0070] The third step: pump the secondary effluent in the second step into the catalytic oxidation tower, and add H in an amount of 1% of the volume of wastewater 2 O 2 Solution (mass fraction of 30%), add 200mg / L ozone, perform O 3 / H 2 O 2 Catalytic oxidation, the reaction time is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com