Horizontal line type plasma surface treatment machine

A surface treatment machine and plasma technology, which is applied in the direction of plasma, printed circuit secondary treatment, electrical components, etc., can solve the problems of poor cleaning effect, single function, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with specific embodiments and drawings.

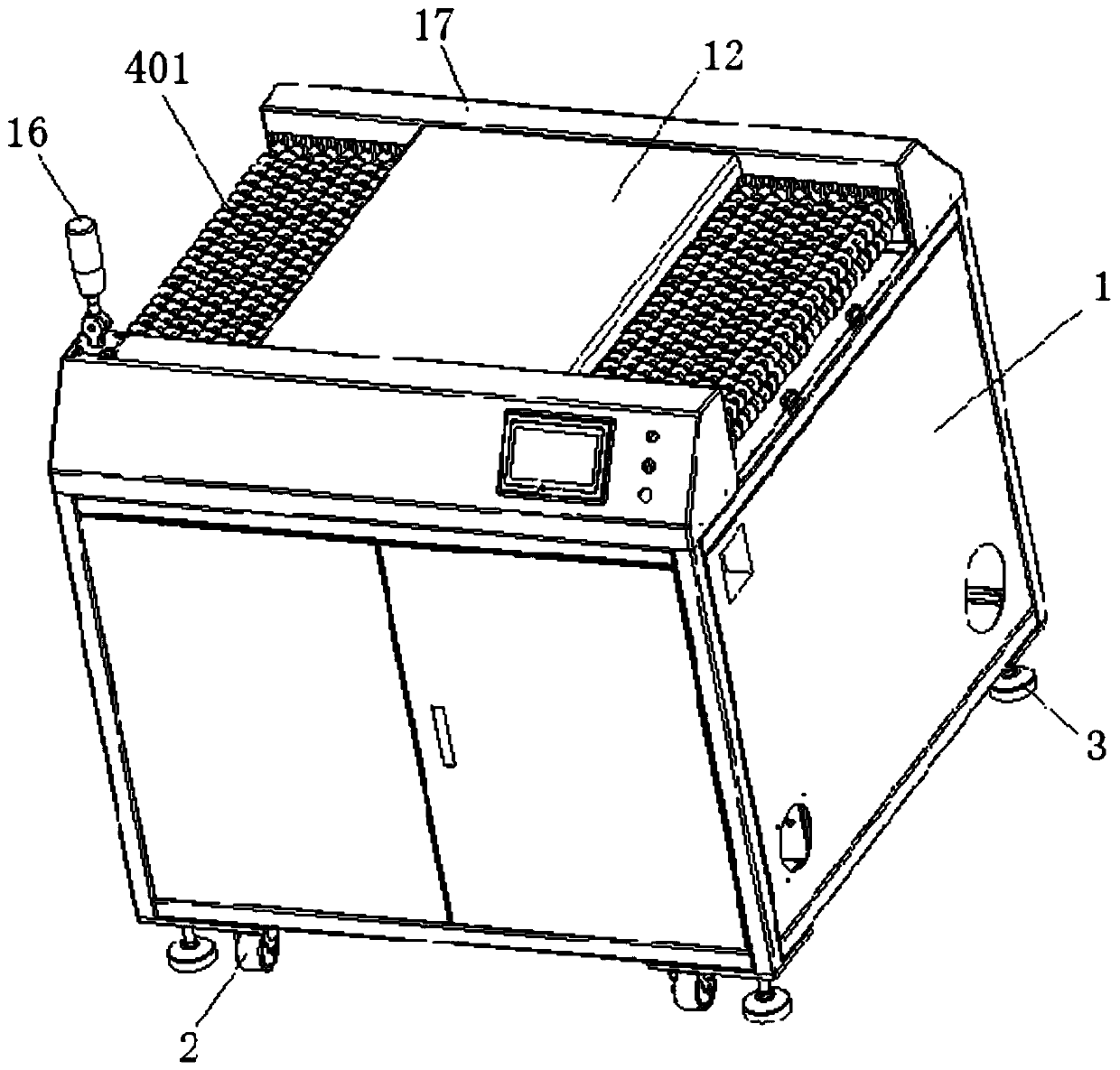

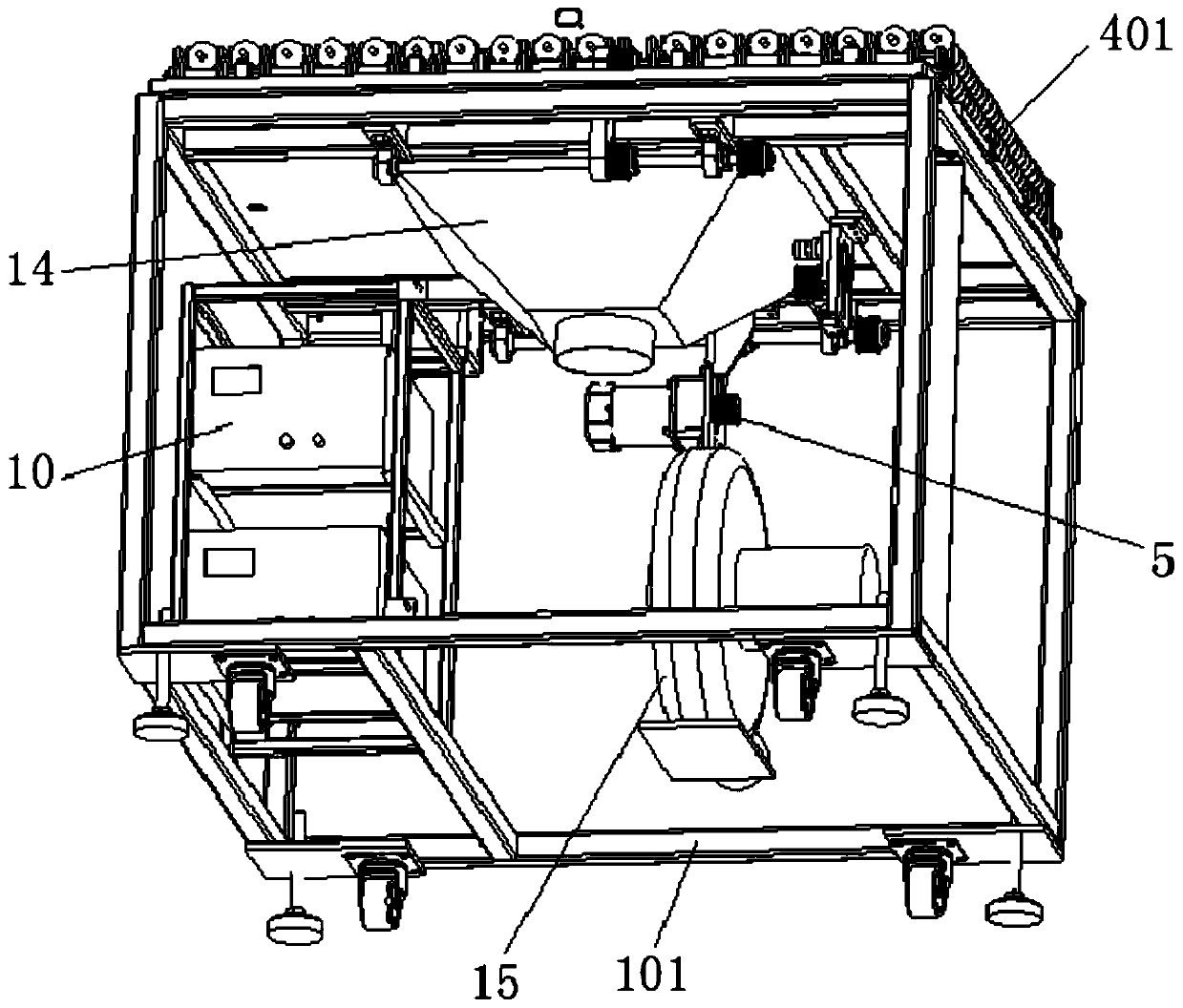

[0047] Such as figure 1 with figure 2 as well as Figure 11 to Figure 15 As shown, a horizontal line type plasma surface treatment machine includes a cabinet-type housing 1. The housing 1 includes a frame 101 and a panel 102 provided on the frame 101. The bottom of the housing 1 is provided with a movable wheel 2 and a supporting foot 3, which is beneficial to the mobile and transportation of the equipment, and the supporting foot 3 can be adjusted in length and is mainly used to fix the equipment. A roller conveying module 4 is installed on the outer top surface of the housing 1, and the roller conveying module 4 is connected with a synchronous belt wheel power module 5. The roller conveying module 4 includes two upper and lower layers of anti-static roller group 401. The two ends of the anti-static roller group 401 are provided with mounting plates, which are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com