Vertical type oxidization wire recycled and reusable two-acid polishing solution and preparation method thereof

A cyclic recovery and oxidation line technology, applied in the polishing field, can solve the problems of respiratory system damage, incomplete cleaning, corrosion of mechanical equipment, etc., and achieve the effect of low polishing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

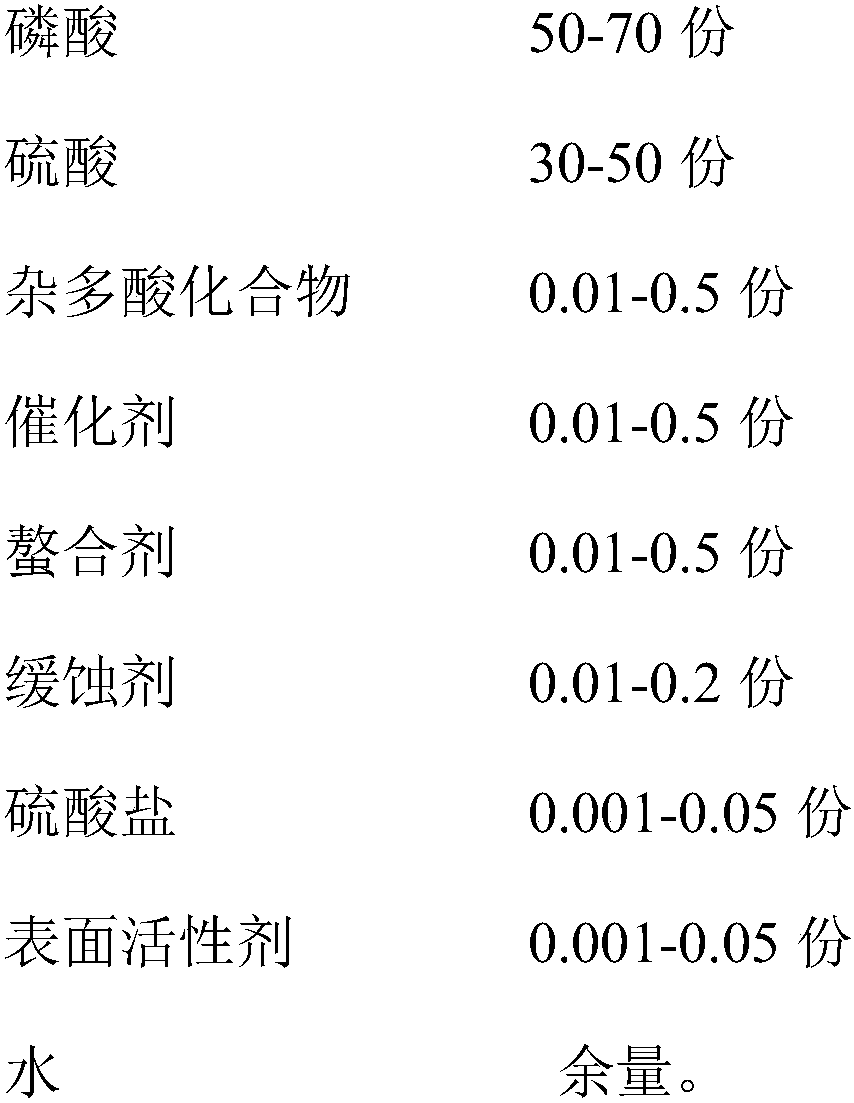

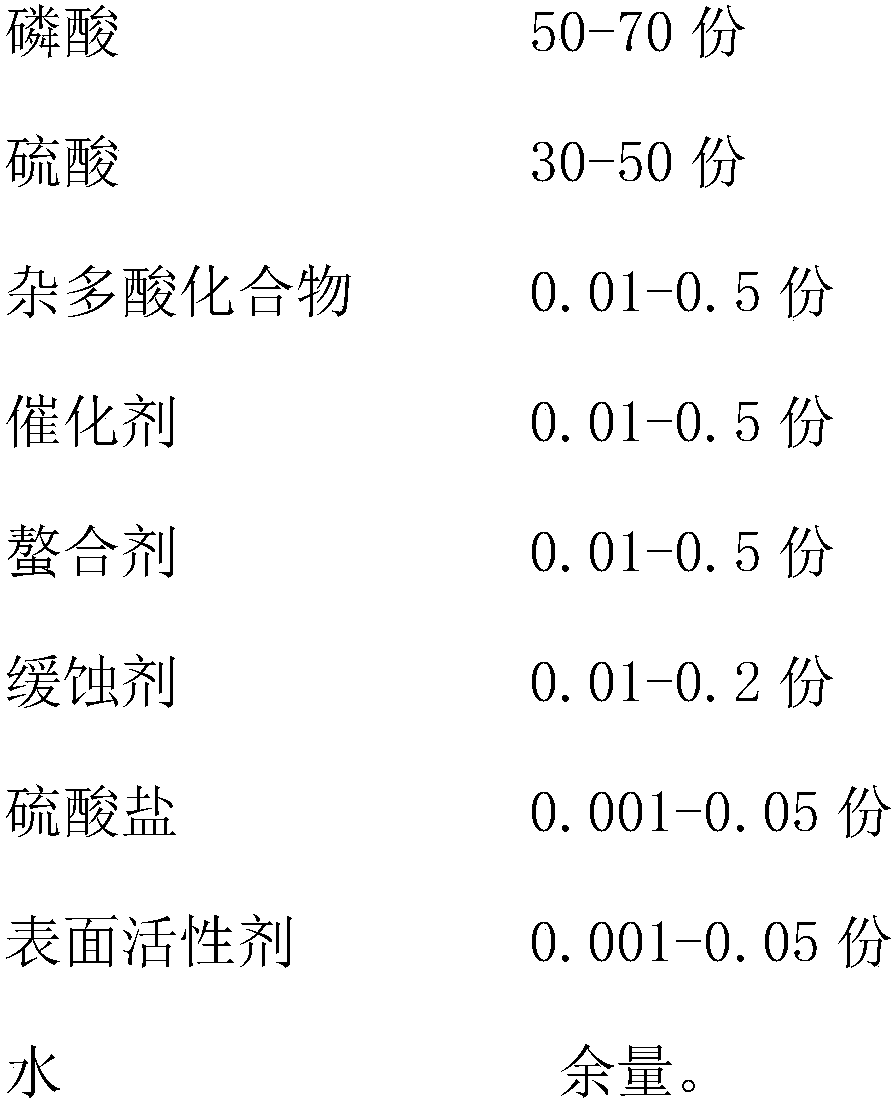

Method used

Image

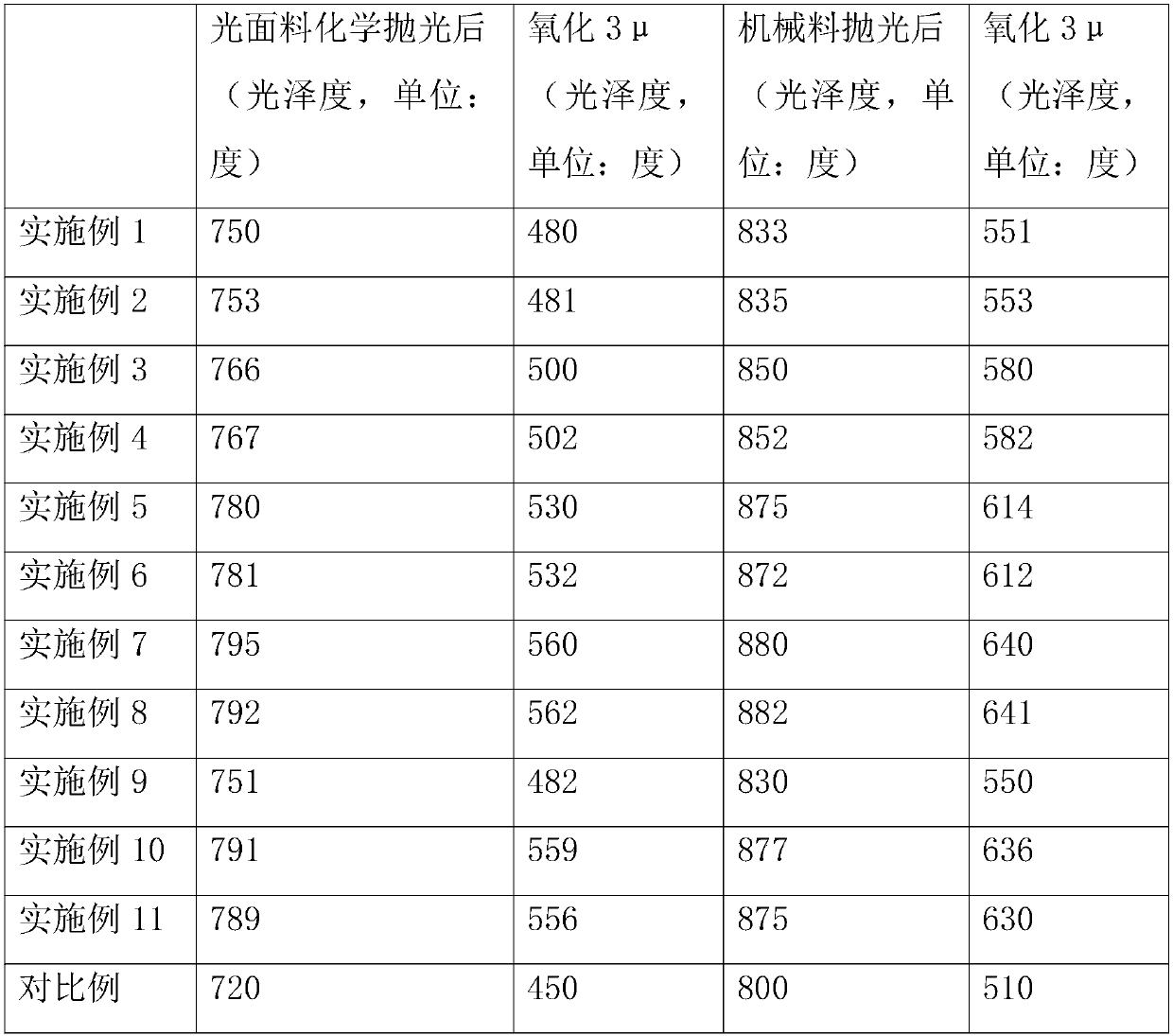

Examples

Embodiment 1

[0033] A vertical oxidation line that can recycle and reuse two acid polishing fluids: 50kg phosphoric acid, 30kg sulfuric acid, 0.01kg 12-tungstosilicate, 0.01kg 12-silicon molybdenum acid, 0.01kg hydrogen peroxide, diethylenetriaminepenta 0.01kg of methylphosphonic acid, 0.01kg of zinc dihydrogen phosphate, 0.001kg of magnesium sulfate, 0.001kg of copper sulfate, 0.001kg of dodecylbenzenesulfonic acid, and 19.947kg of water.

[0034] The above preparation method is as follows:

[0035] Step (1): Weigh each component in Example 1 respectively, dissolve diethylene triamine pentamethylene phosphonic acid, zinc dihydrogen phosphate, magnesium sulfate, copper sulfate, and dodecylbenzenesulfonic acid in water, Get the solution for later use.

[0036] Step (2): Add phosphoric acid, sulfuric acid, 12-tungstosilicic acid and 12-silicomolybdic acid into the reaction vessel, then add the solution in step (1) into the reactor and stir evenly.

Embodiment 2

[0039] Phosphoric acid 50kg, sulfuric acid 30kg, 12-tungstosilicate 0.01kg, 12-silicomolybdic acid 0.01kg, hydrogen peroxide 0.01kg, diethylenetriaminepentamethylenephosphonic acid 0.01kg, zinc dihydrogen phosphate 0.01kg, magnesium sulfate 0.001kg, copper sulfate 0.001kg, sodium lauryl sulfate 0.001kg, water 19.947kg.

Embodiment 3

[0041] Phosphoric acid 60kg, sulfuric acid 30kg, 12-tungstosilicate 0.25kg, 12-silicomolybdic acid 0.25kg, hydrogen peroxide 0.25kg, diethylenetriaminepentamethylenephosphonic acid 0.25kg, zinc sulfate 0.11kg, magnesium sulfate 0.025kg , copper sulfate 0.025kg, dodecylbenzenesulfonic acid 0.025kg, water 8.815kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gloss | aaaaa | aaaaa |

| Gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com