Diesel engine exhaust emission purifying system

A diesel engine and exhaust gas emission technology, which is applied to engine components, machines/engines, exhaust devices, etc., can solve problems such as high hazards and increased particulate matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

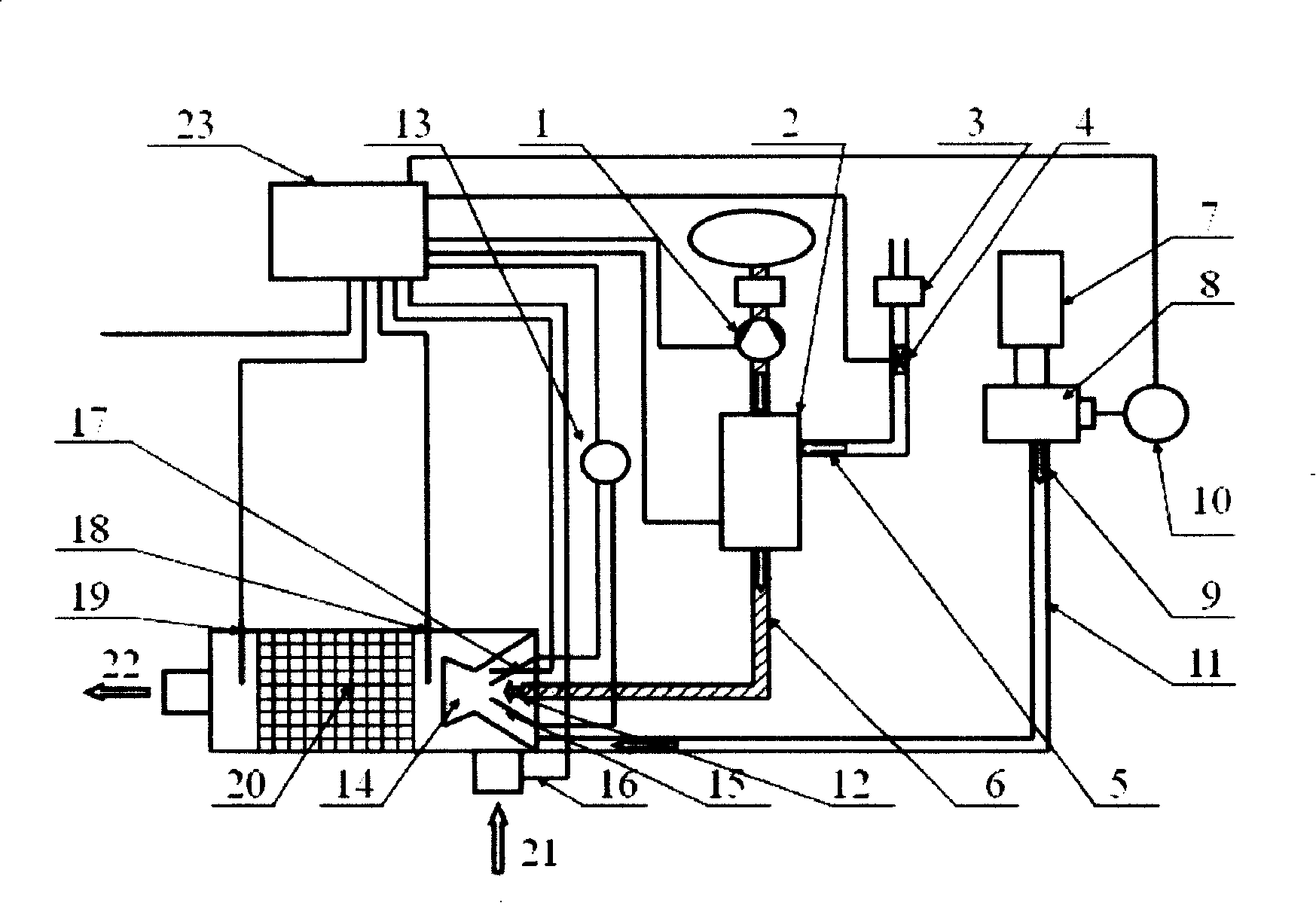

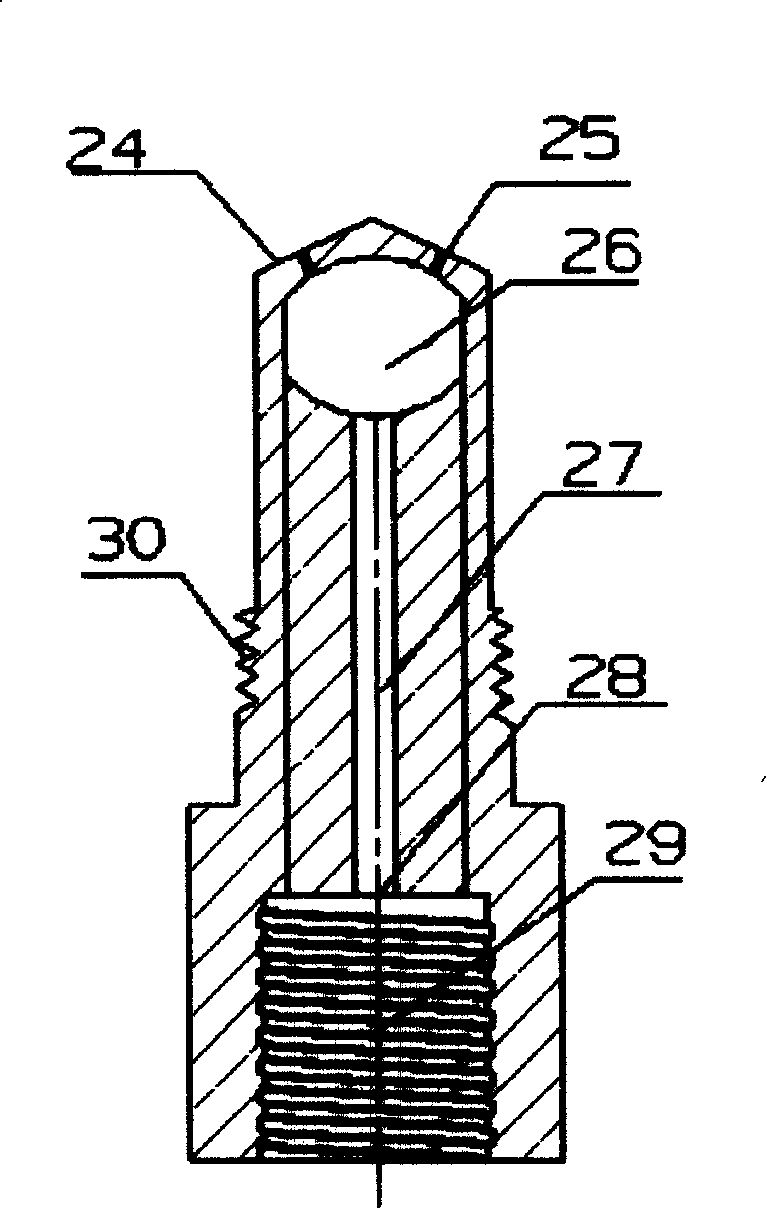

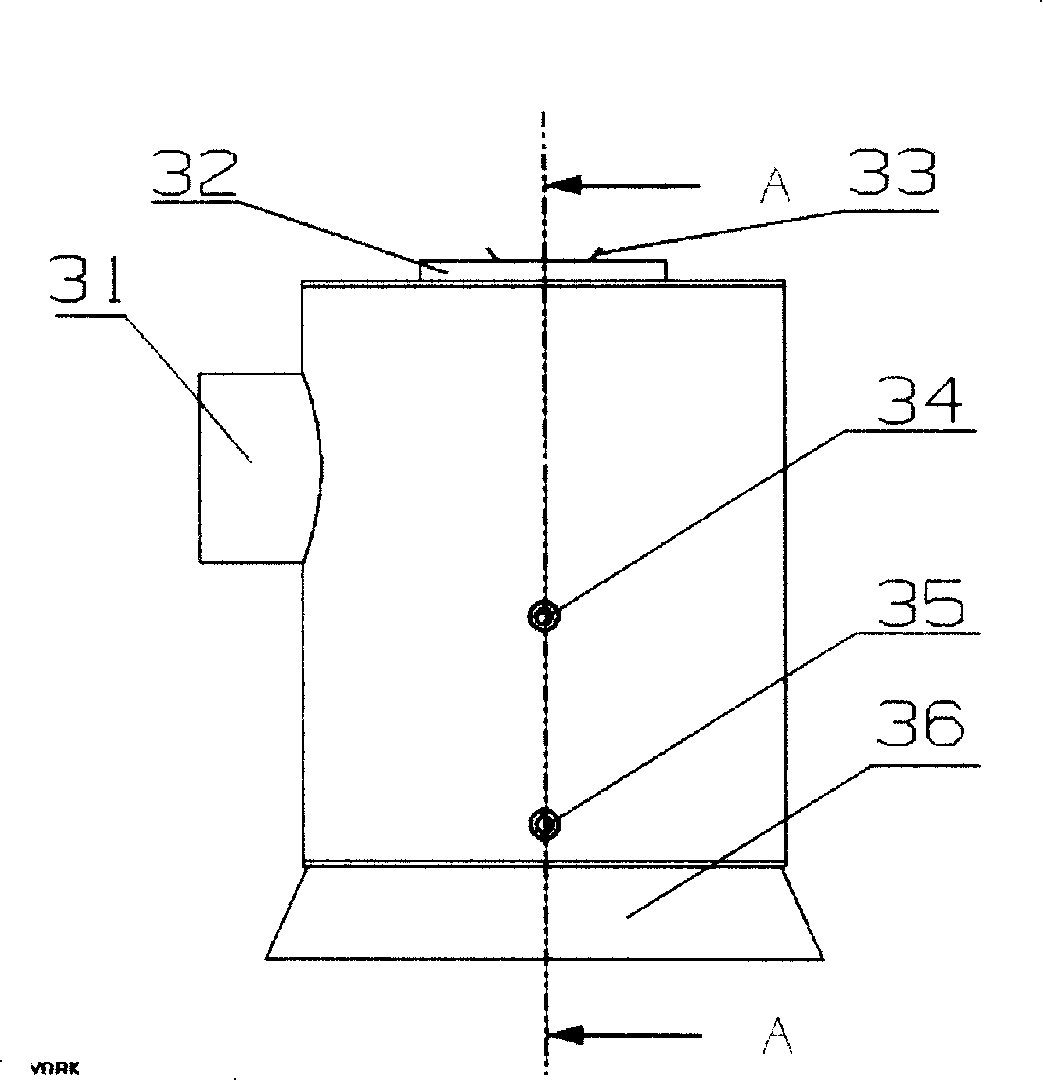

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] like figure 1 Shown: the diesel vehicle exhaust emission purification device of the present invention includes the following parts: the diesel vehicle particle filter DPF (20) is a wall-flow filter body, which can be made of materials such as cordierite or silicon carbide. The filtration efficiency of particulate matter exceeds 95%. The exhaust gas discharged from the diesel engine enters the purification device from the air inlet (21), is filtered by the diesel vehicle particle filter DPF (20), and is discharged from the outlet (22). The pressure sensor (16) installed in the engine exhaust port (21) will continuously transmit the exhaust back pressure signal to the electronic control unit ECU (23). To a certain extent, when the signal sent by the pressure sensor (16) to the electronic control unit ECU (23) is higher than the set value, the electroni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com