Method of Drying Biomass

a technology of biomass and drying method, which is applied in the direction of biofuels, waste based fuels, fuels, etc., can solve the problems of increasing the transportation cost of materials and not addressing product cooling, and achieve the effect of enhancing the distribution of water added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

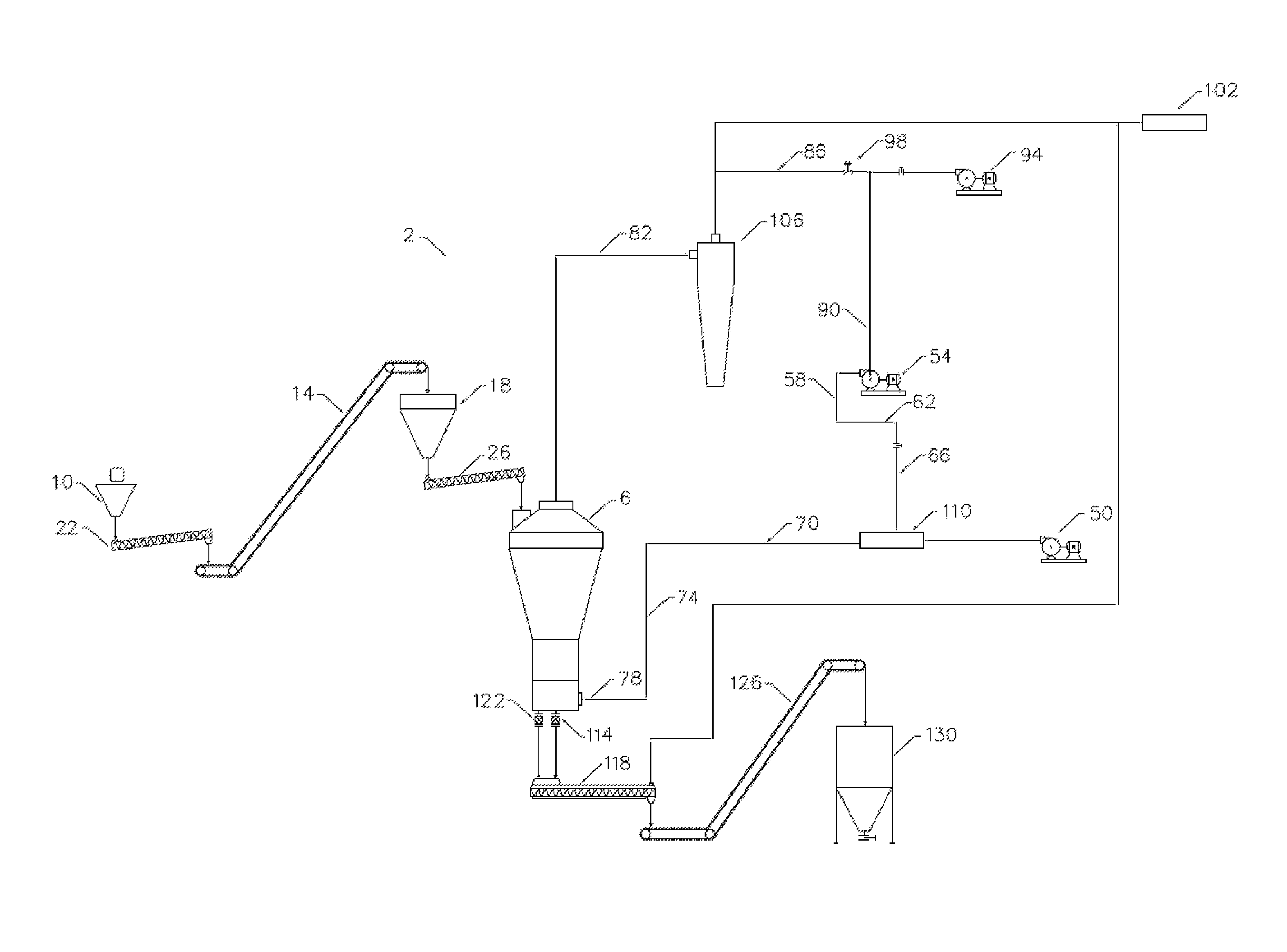

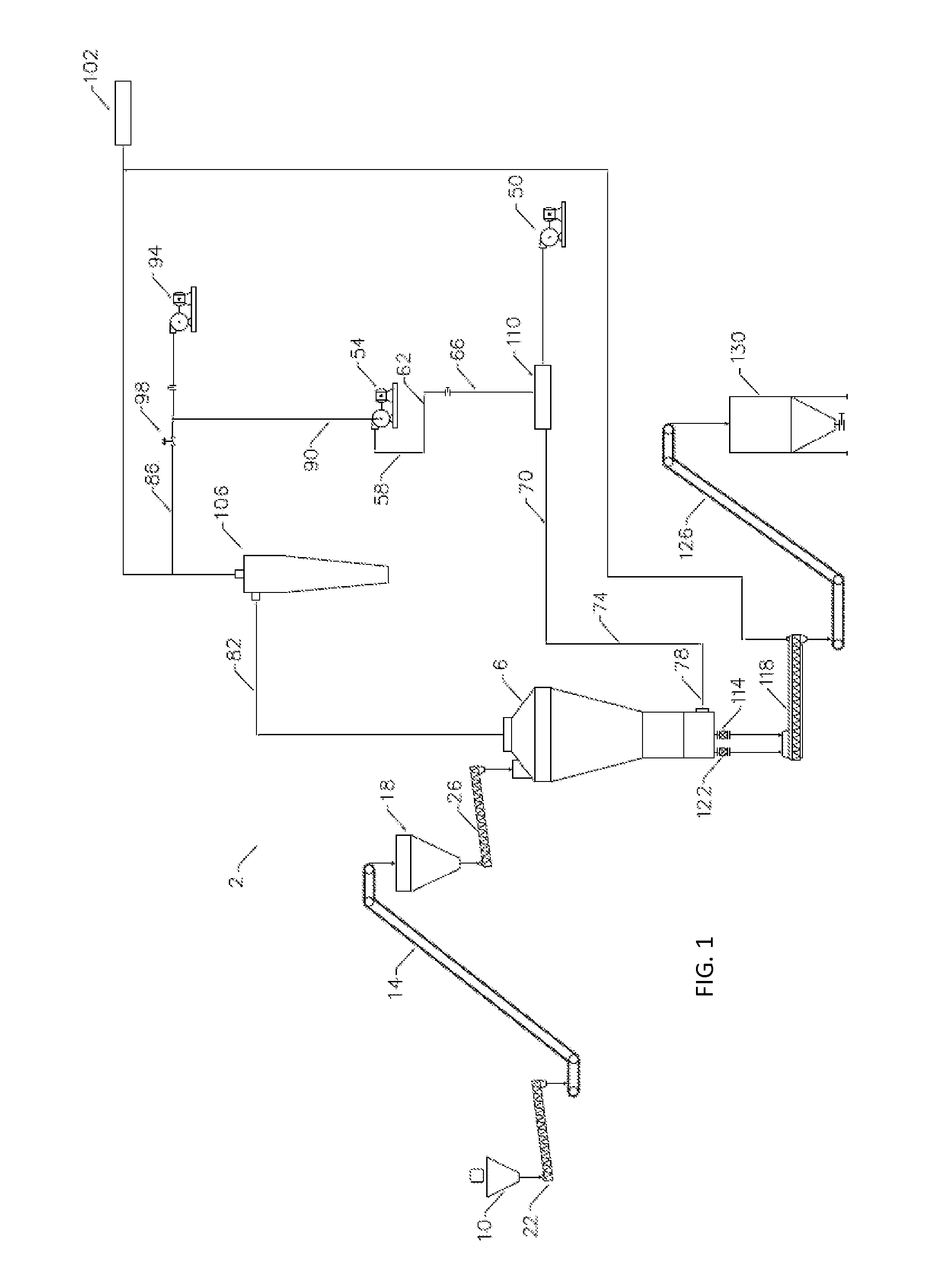

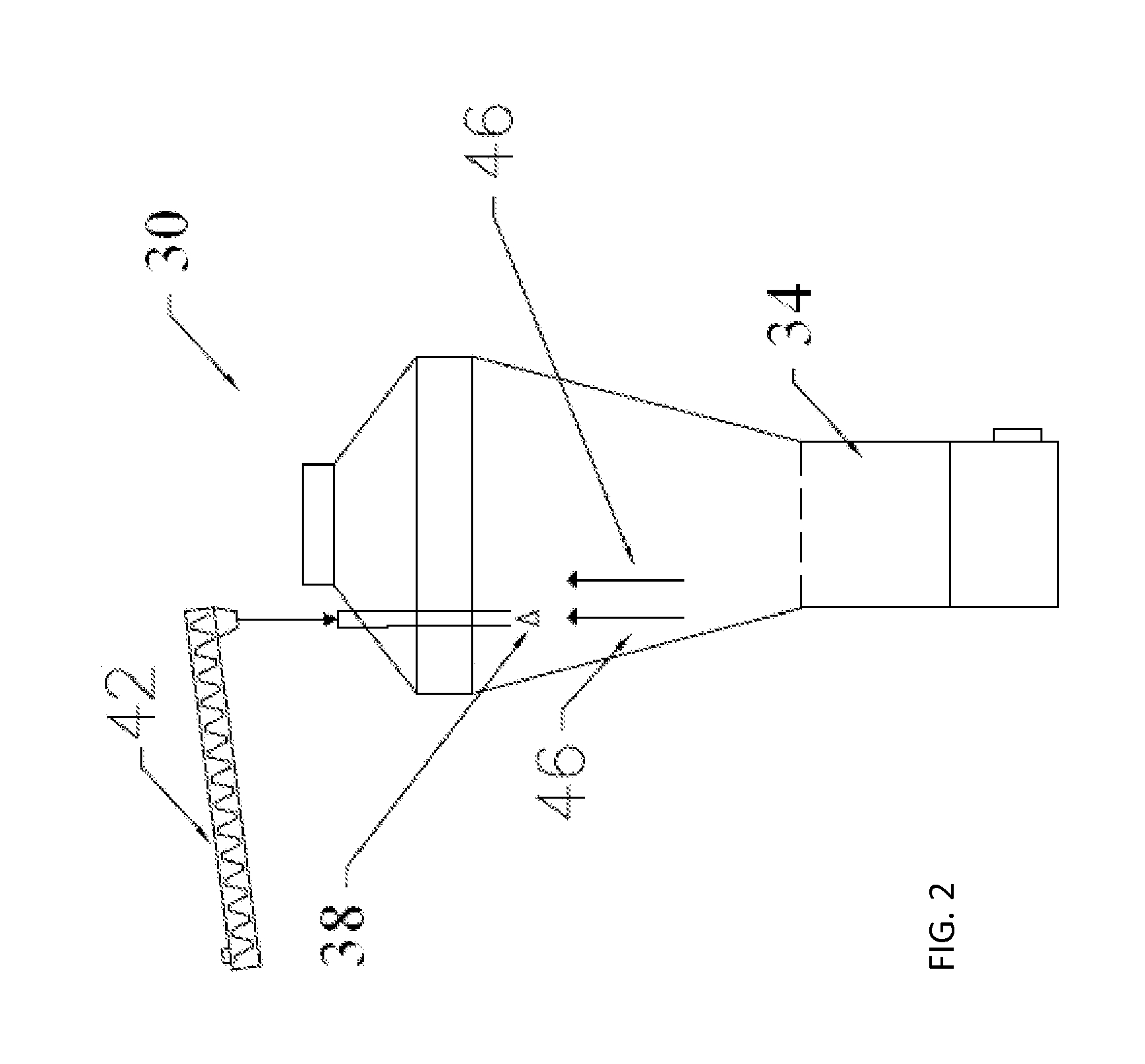

[0054]Referring now to FIG. 1, a biomass torrefaction system 2 implements a process for preparing torrefied biomass. More specifically, one embodiment of the present invention employs a fluidized bed reactor 6 wherein a fluid or gas is passed through a granular solid biomass material at high velocities to suspend the solid and cause it to behave as if it were fluid (i.e. fluidization). The biomass may be wood that has been reduced in size by a commercially available wood chipper. The size of the biomass will vary, but the smallest dimension is typically about 3 mm to 10 mm thick. One of skill in the art will appreciate that straw or other agricultural waste may be used without departing from the scope of the invention. In one embodiment, biomass having about 10 to 50 weight percent moisture is processed The weight percentage is, preferably, determined by conventional methods in accordance with standard A.S.T.M. testing procedures.

[0055]The biomass torrefaction system 2 receiving fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com