Batch pyrolysis system

a pyrolysis system and batch technology, applied in the field of continuous batch pyrolysis systems, can solve the problems of difficult opening of new sites, less availability of storage or land filling sites of waste tires, and major environmental problems of waste vehicle tires, and achieve the effect of high throughput and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

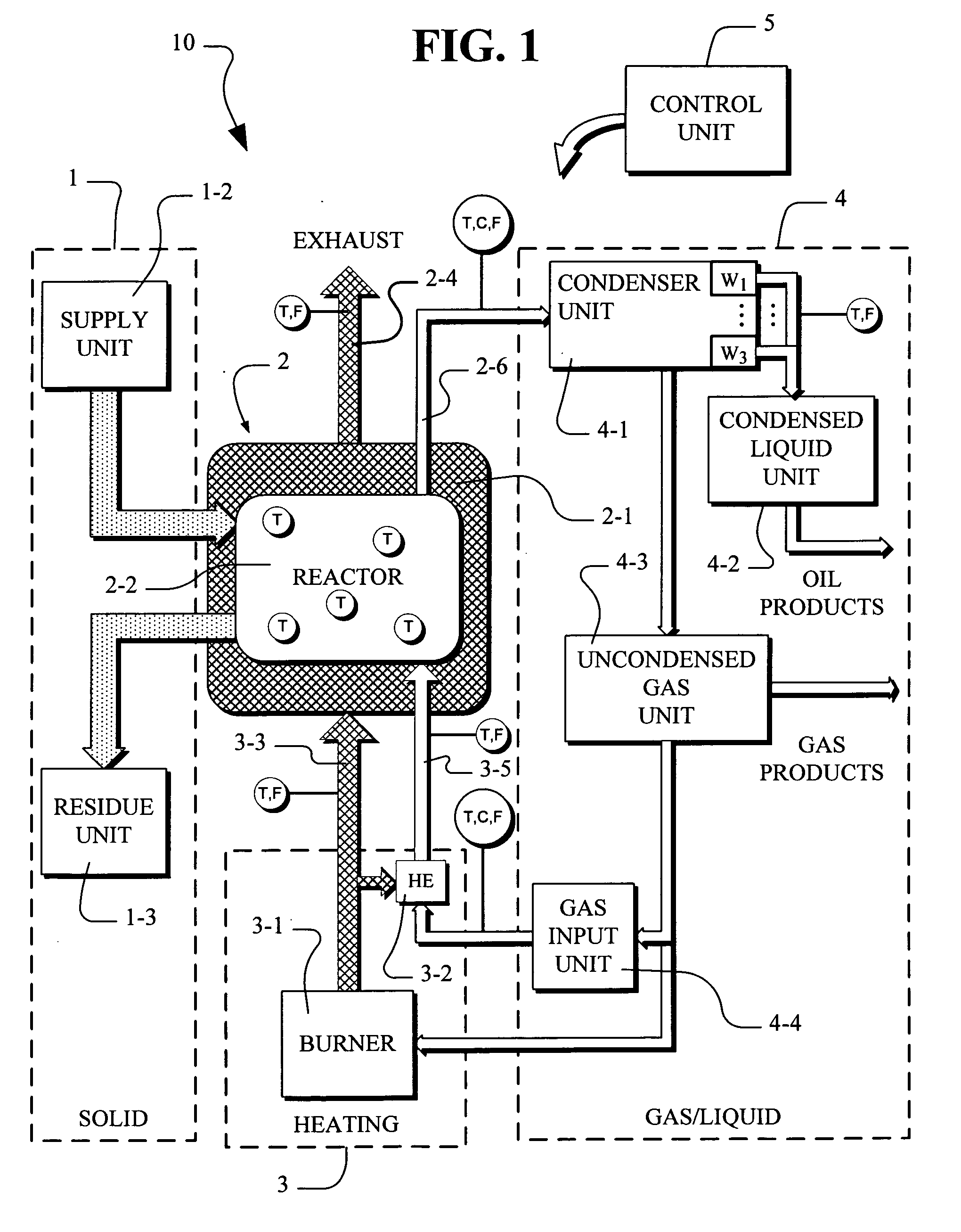

[0041]FIG. 1, a schematic block diagram of the batch pyrolysis system 10 is shown. The batch pyrolysis system 10 includes the solid processing units 1, the reactor 2, the heating units 3, the gas / liquid units 4 and the control unit 5.

[0042] In FIG. 1, the solid processing units 1 include the supply unit 1-2 and the residue unit 1-3. The supply unit 1-2 functions to introduce waste tires or other supply material into the reactor 2. The waste tires can be either in the form of whole tires or cut tires. Typically, tires are washed and cleaned in a washing machine in supply unit 1-2 to remove foreign matter such as dirt, oil, sand or other undesirable material. The cleaning is done with heated water or steam generated by fuel or heat available from the pyrolysis system 10. The cleaning process also typical functions to preheat the waste tires prior to placement in the reactor 2-2. The waste tires are placed into the reactor 2 in either a whole or cut condition. When cut, the cutting ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com