High-efficiency clean low-carbon coal graded utilization method and device

A clean and efficient technology, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. It can solve the problems of insufficient use of high value-added components of fuels, etc., and achieve the expansion of the applicable range of coal types and high purity. , the effect of easy purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

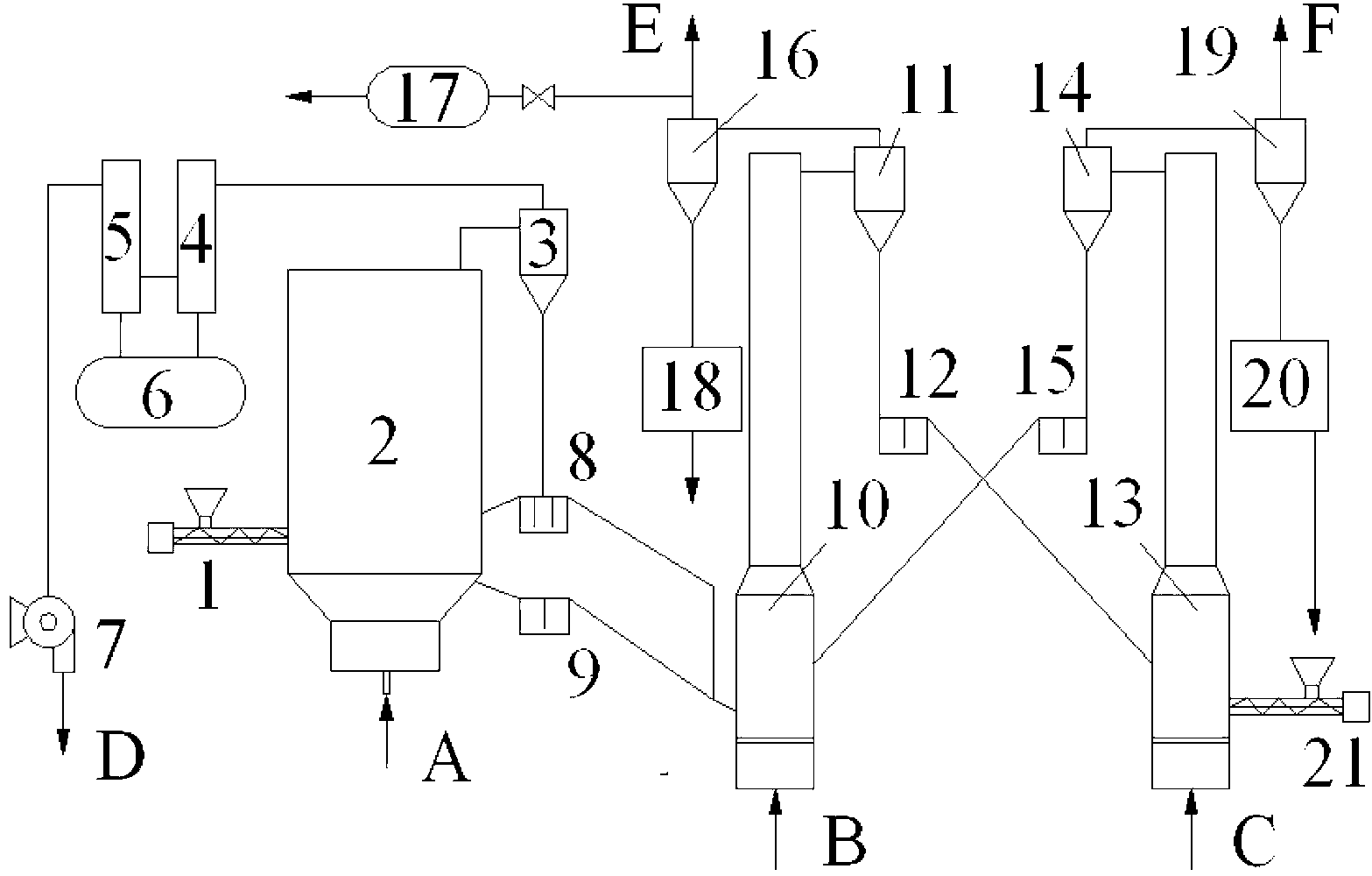

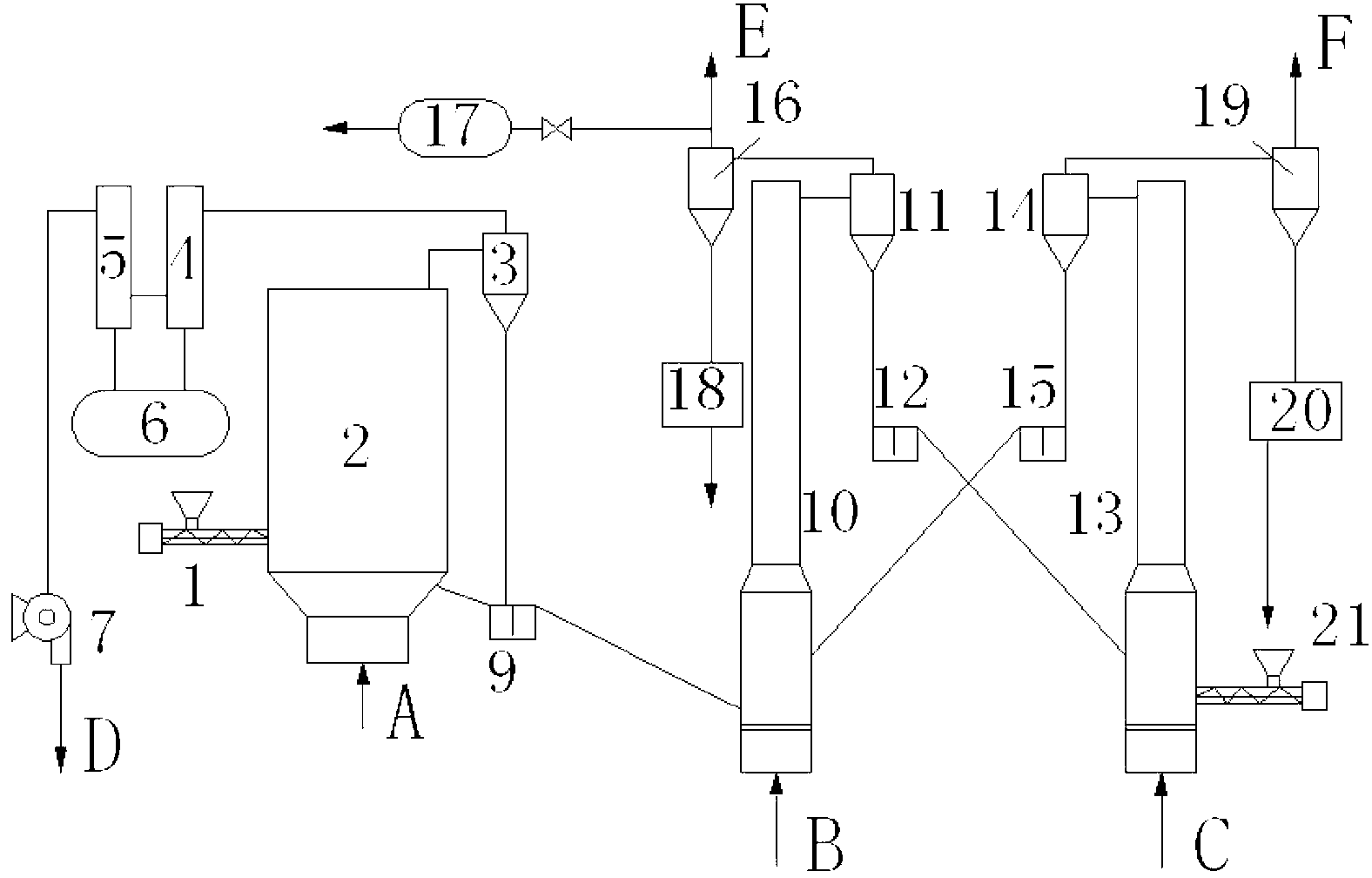

[0058] In this example, water vapor is selected as the fluidization gas of pyrolysis furnace reactor 2, and water vapor is introduced from the inlet of pyrolysis furnace reactor 2; Carrier, after the whole system is running, adjust the amount of hot ash sent to the pyrolysis furnace reactor 2 and the temperature of the fluidization gas, and control the temperature in the pyrolysis furnace reactor 2 at about 500°C;

[0059] a) Pulverized coal particles are thermally decomposed in the pyrolysis furnace reactor 2, and volatile matter, water vapor, etc. are precipitated, and the gas products are brought into the first cyclone separator 3 by the fluidization gas together with some fly ash particles, and the separated solid particles pass through The two-way feeder 8 is sent into the pyrolysis furnace reactor 2 or the fuel reactor 10; at the same time, the remaining pyrolysis semi-coke in the pyrolysis furnace reactor 2 is directly sent into the fuel reactor 10 through the first flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com