Coal-gas-circulation coal whole-size-grading pyrolytic coupling hot-pressing formed coke preparation technique and system

A preparation system and graded pyrolysis technology, which is applied in the field of coal gas circulation coal full particle size graded pyrolysis coupling hot-pressed coke preparation process and system, can solve the problems of low dust removal efficiency and high dust content of pyrolysis gas dedusting technology, Achieve the effect of realizing waste reuse, saving coking coal resources and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

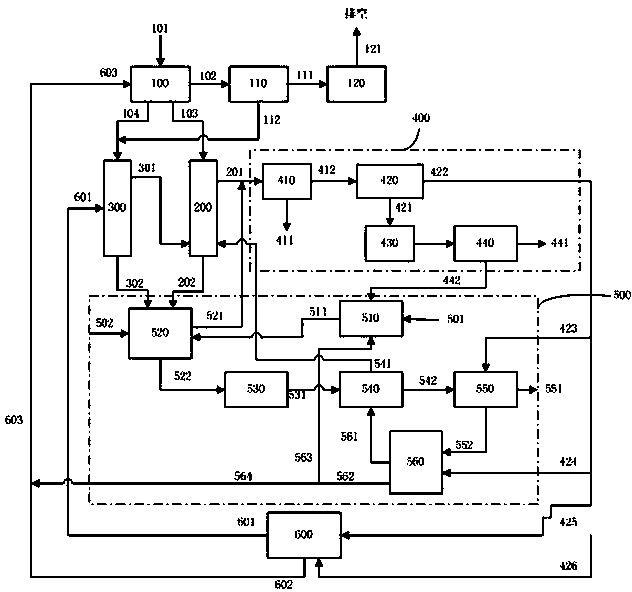

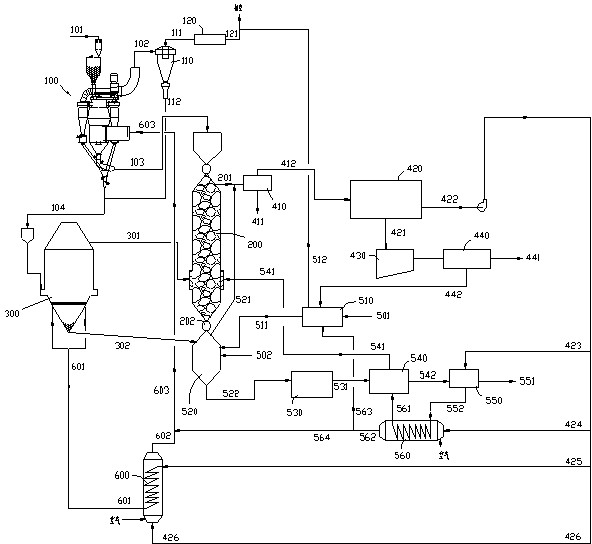

[0054] like figure 2 As shown, the coal gas circulation coal full particle size classification pyrolysis coupled hot-pressed coke preparation system of the present invention includes: raw coal preheating classification system 100, granular coal pyrolysis furnace 200, powder coal pyrolysis furnace 300, pyrolysis gas treatment system 400 , a hot-pressed coke preparation system 500 , and a pyrolysis gas heating furnace 600 . The raw coal preheating and grading system also includes a dust collector 110 and a desulfurization device 120; the pyrolysis gas treatment system includes a fine dust collector 410, a gas cooling device 420, a tar tank 430 and a tar filter 440; the hot-pressed coke The preparation system includes a coal tar pitch melting tank 510 , a stirring tank 520 , a forming machine 530 , a carbonization furnace 540 , a cooler 550 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com