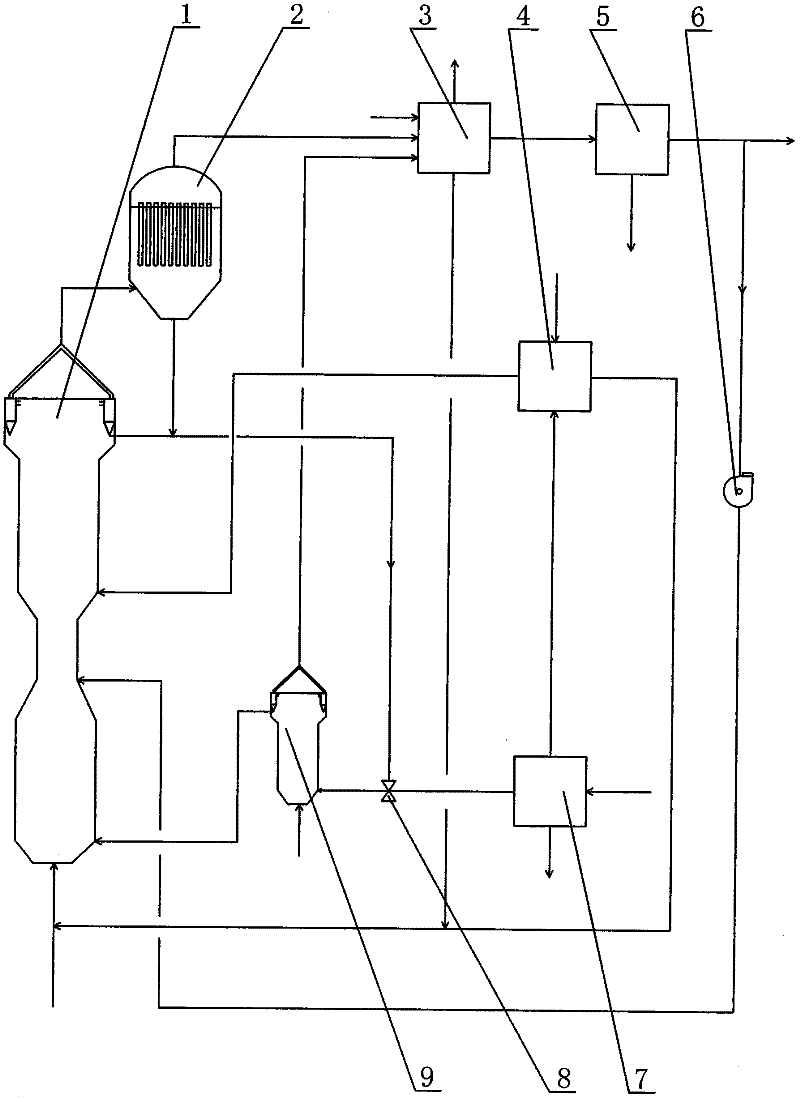

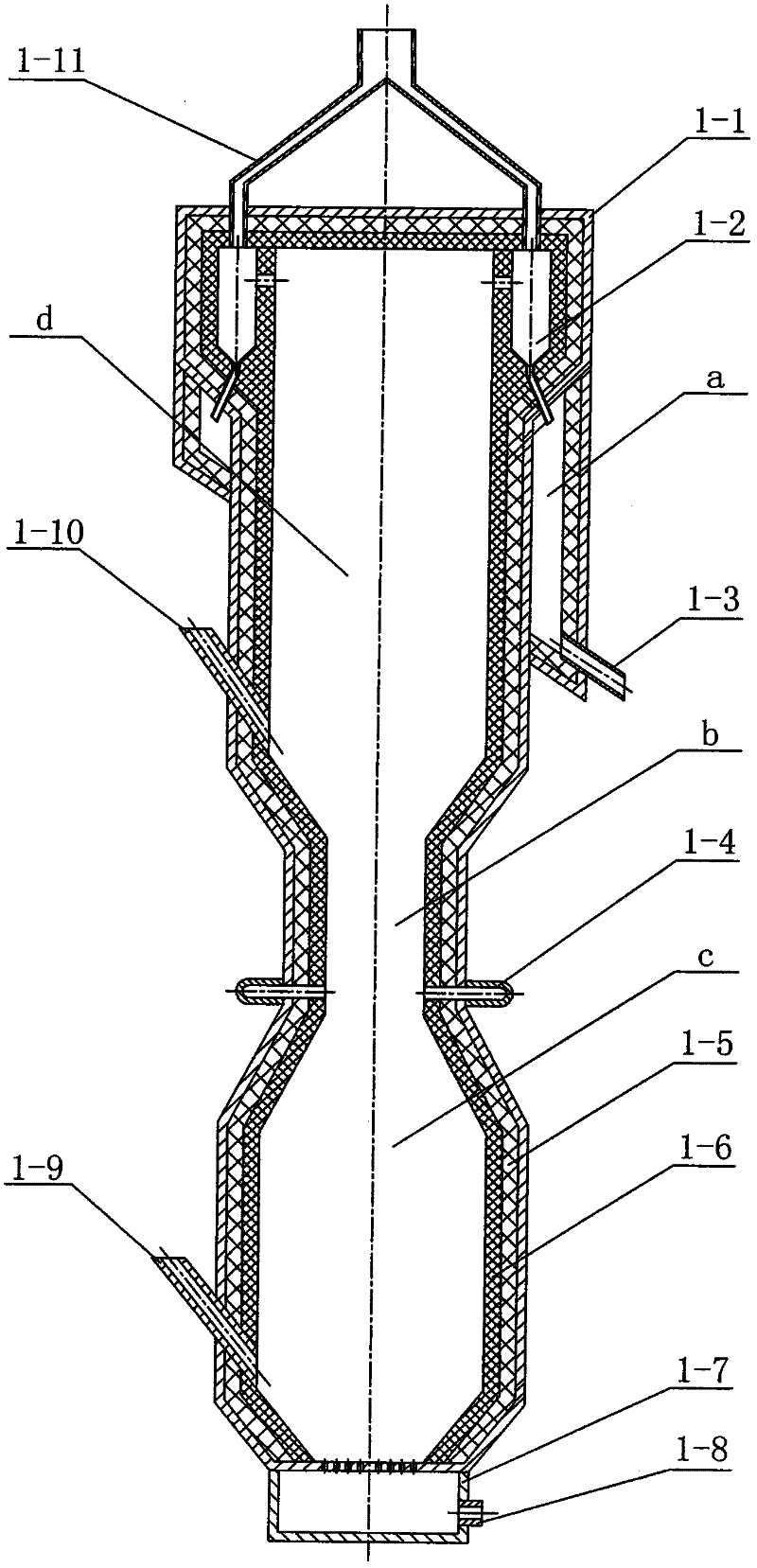

Device for preparing coal tar and coal gas by coupling semi-coke powder gasification and reformed gas pyrolysis and method using same

A technology for coal tar and reformed gas, which is applied in the field of coal chemical industry and achieves the effects of simple process, high yield and little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

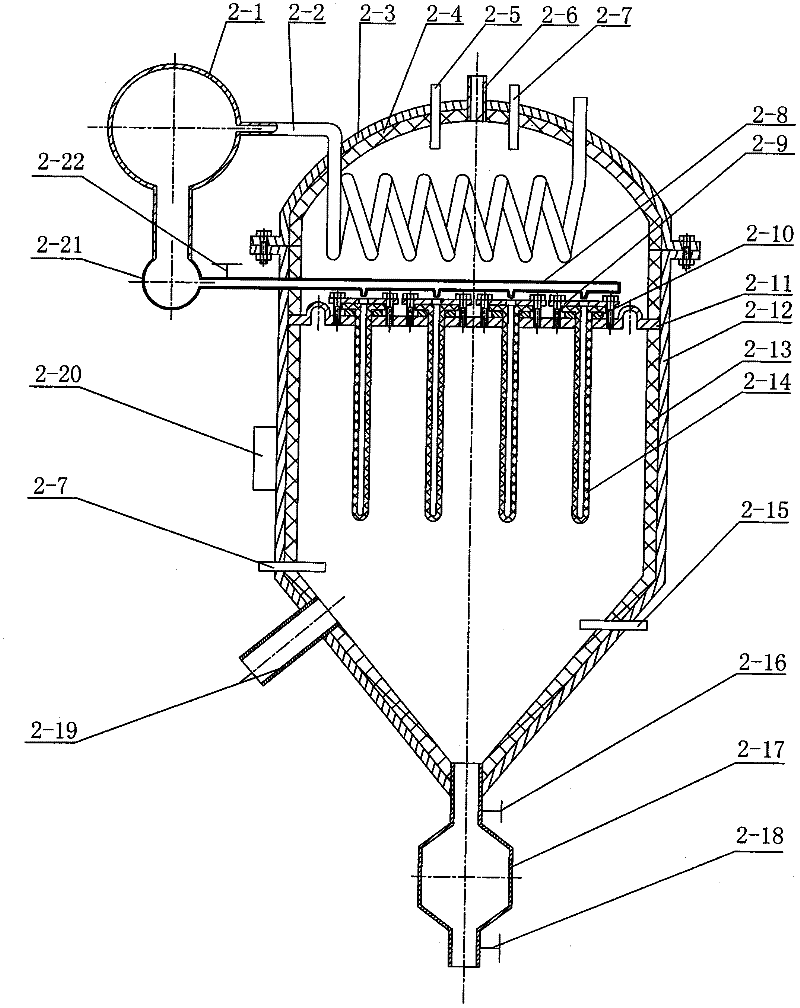

Embodiment 2

[0050] In this embodiment, 16 rows of ceramic filter cores 2-14 are installed on the mounting plate 2-11, and each row is provided with 8 ceramic filter cores 2-14, and the ceramic filter cores 2-14 installed on each row and installed The number of rows installed on the plate 2-11 should be specifically determined according to the cross-sectional area in the filter housing 2-12, and each row of ceramic filter cores 2-14 is arranged equidistantly, and a row of ceramic filter cores 2-14 is adjacent to one row. Rows of ceramic filter cores 2-14 are arranged in a staggered manner, and the inner diameter of the ceramic filter cores 2-14 is 100mm. Each row of filter elements communicates with the blowback main pipe 2-21 through a quick-opening ball valve 2-22 installed on a blowback pipe 2-8. Other components and the coupling relationship of the components are the same as in Embodiment 1.

[0051] The method for preparing coal tar and coal gas using the apparatus of this embodiment...

Embodiment 3

[0053] In this embodiment, 12 rows of ceramic filter elements 2-14 are installed on the mounting plate 2-11, each row is provided with 12 ceramic filter elements 2-14, and the ceramic filter elements 2-14 installed on each row are connected with the The number of rows installed on the plate 2-11 should be specifically determined according to the cross-sectional area in the filter housing 2-12, and each row of ceramic filter cores 2-14 is arranged equidistantly, and a row of ceramic filter cores 2-14 is adjacent to one row. Rows of ceramic filter cores 2-14 are arranged in a staggered manner, and the inner diameter of the ceramic filter cores 2-14 is 60mm. Each row of filter elements communicates with the blowback main pipe 2-21 through a quick-opening ball valve 2-22 installed on a blowback pipe 2-8. Other components and the coupling relationship of the components are the same as in Embodiment 1.

[0054] The method for preparing coal tar and coal gas using the apparatus of t...

Embodiment 4

[0056] In the above embodiments 1-3, the rows of ceramic filter elements 2-14 installed on the mounting plate 2-11 are replaced with stainless steel filter elements. The other components and the coupling relationship of the components are the same as those in the corresponding embodiments.

[0057] The method for preparing coal tar and coal gas using the apparatus of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com