Coal pyrolysis reactor

A technology of pyrolysis reactor and reactor, which is applied in the direction of direct heating dry distillation, special form dry distillation, petroleum industry, etc., can solve the problems of ash, can not solve the problem of insufficient pyrolysis reaction of oil and coal, and reduce the content of dust , Improve the utilization rate and improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Various preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

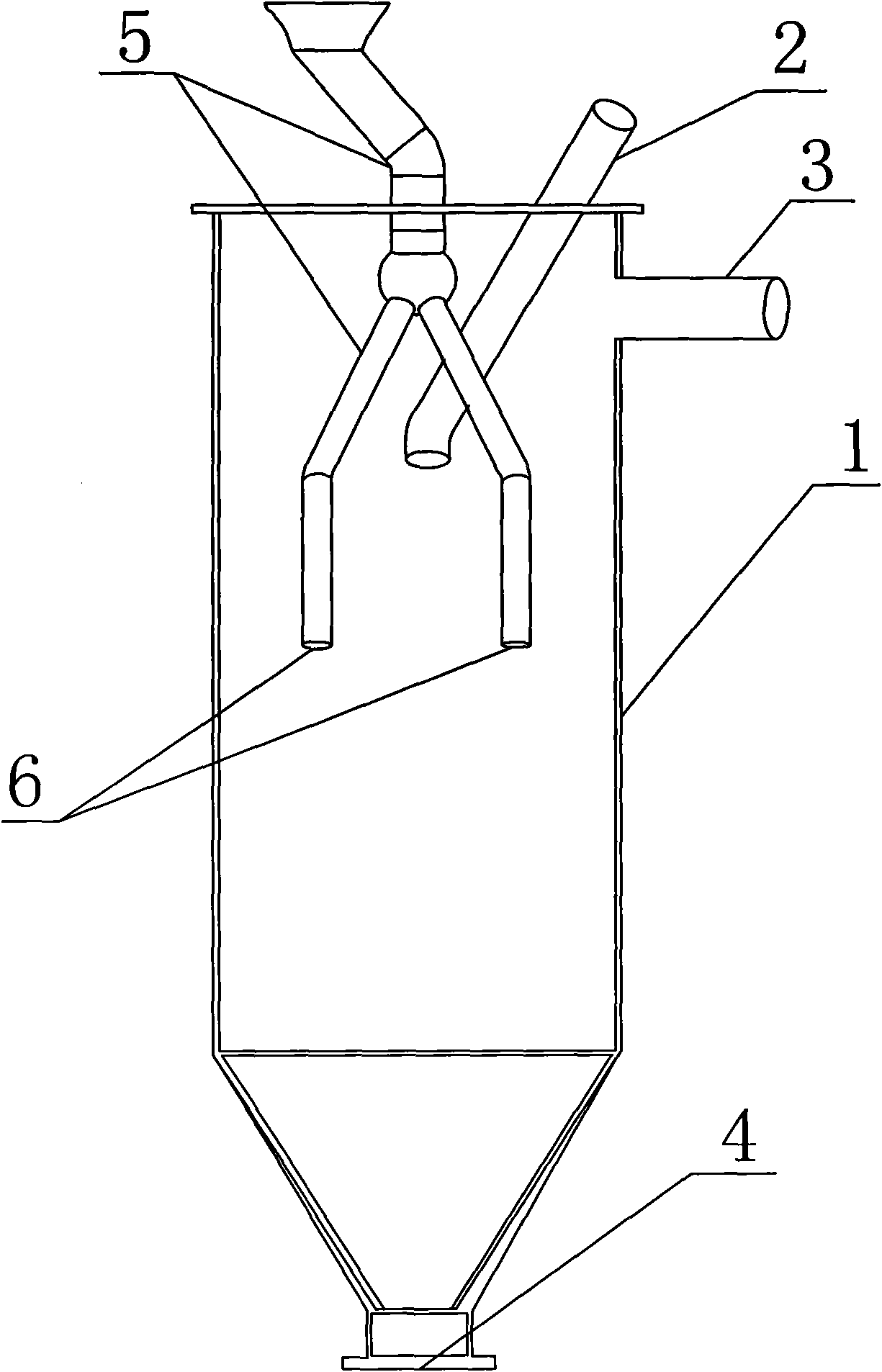

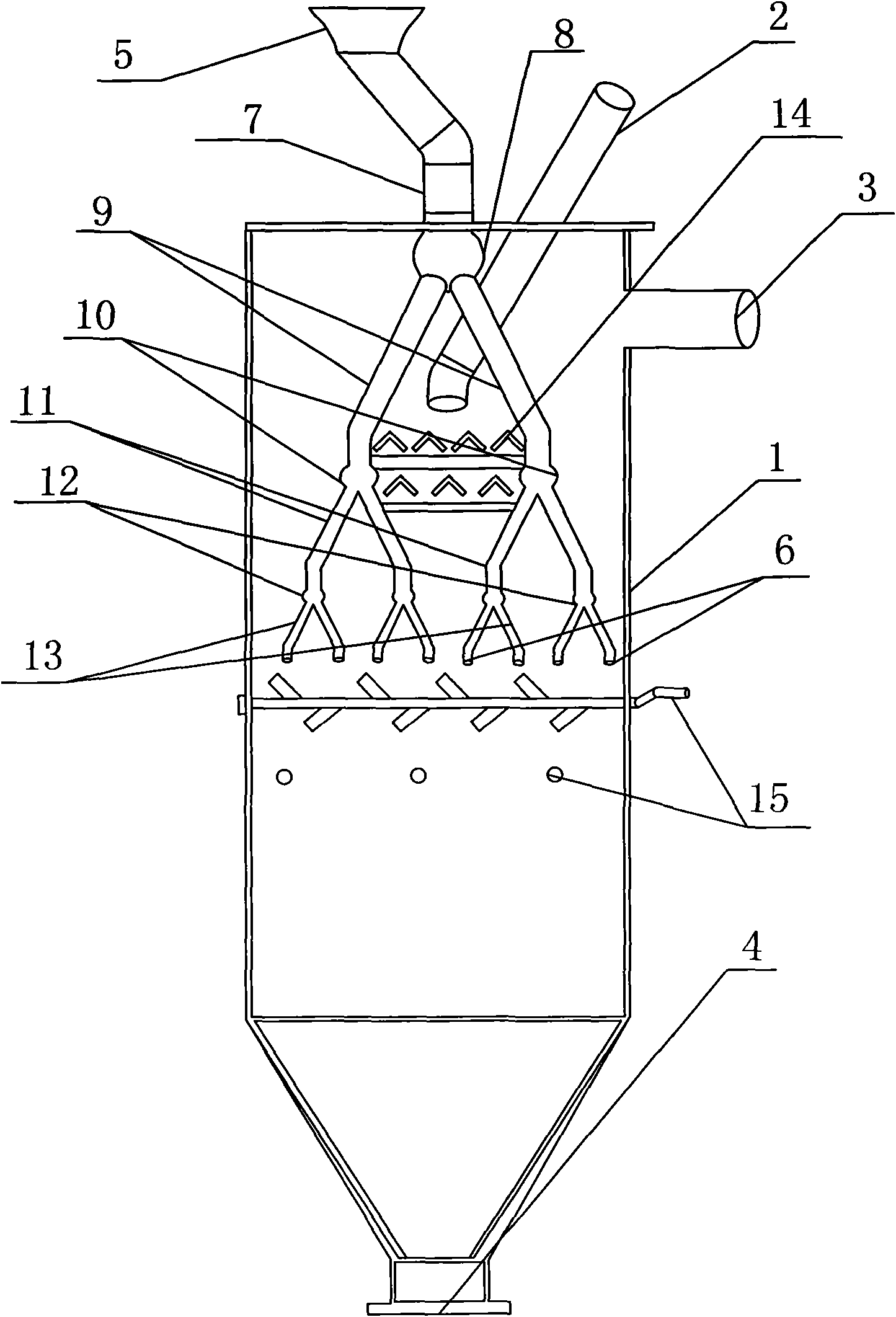

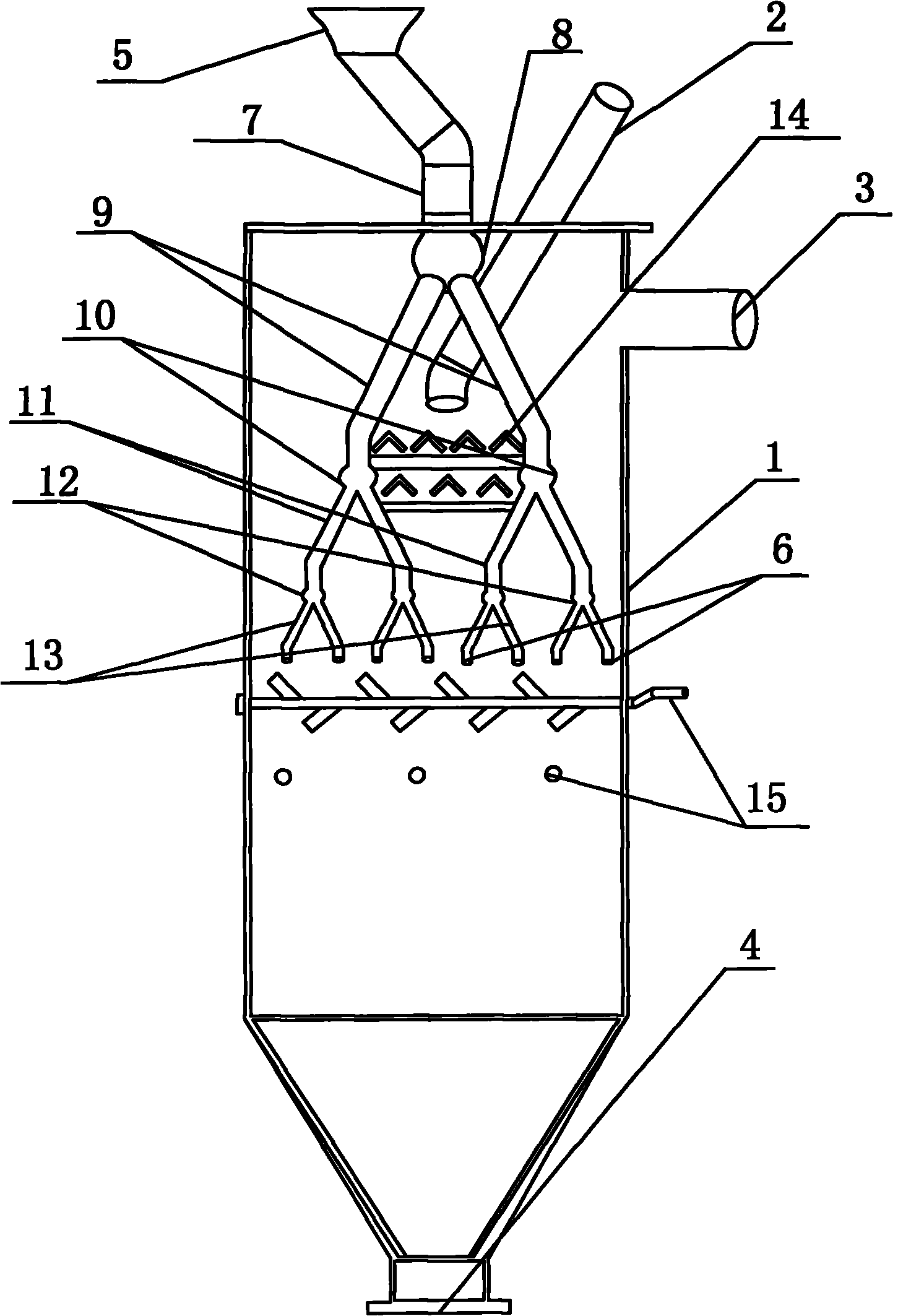

[0021] The invention provides a coal pyrolysis reactor, in which a pipeline structure close to an inverted tree structure or other shapes is arranged to divide the high-temperature solid heat carrier, and the above-mentioned high-temperature heat carrier is a high-temperature granular medium , can also be called granular heat carrier, which can fully mix the high-temperature granular medium with raw coal, improve the pyrolysis efficiency of coal, and reduce the content of dust carried in the product. Such as figure 1 As shown, the coal pyrolysis reactor includes a pyrolysis reactor 1, and the upper part of the pyrolysis reactor 1 is provided with a raw coal pipe 2 for introducing coal raw materials and an export pipeline 3 for exporting coal pyrolysis gas phase products, The bottom of the pyrolysis reactor is provided with a discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com