Method and device for preparing methane-containing gas by using coal

A methane and gas technology, which is used in the field of coal gasification to prepare substitute natural gas, can solve the problems of uneven heating of the solid phase of the bed, high carbon content in the residue, and slow heat transfer rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

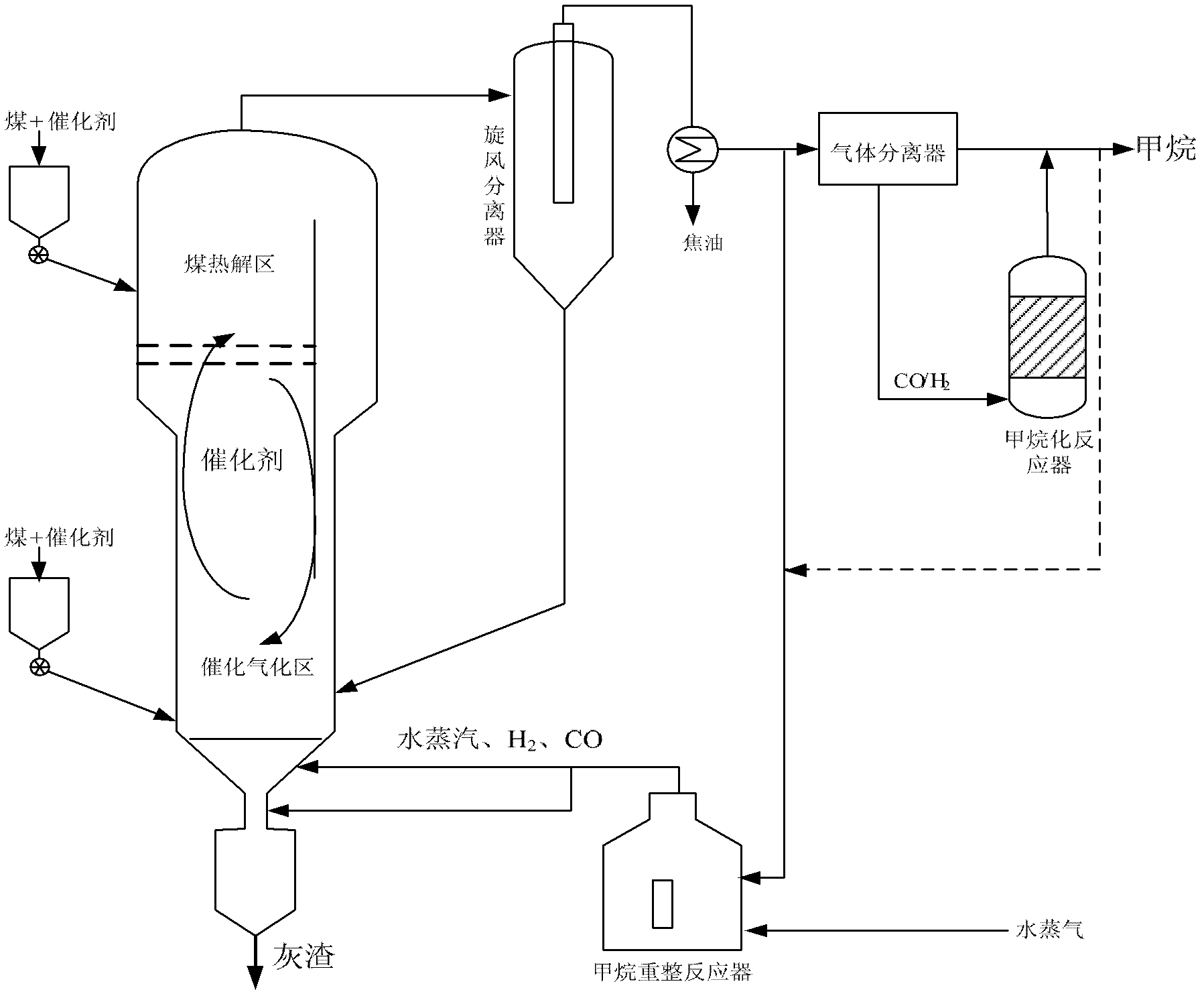

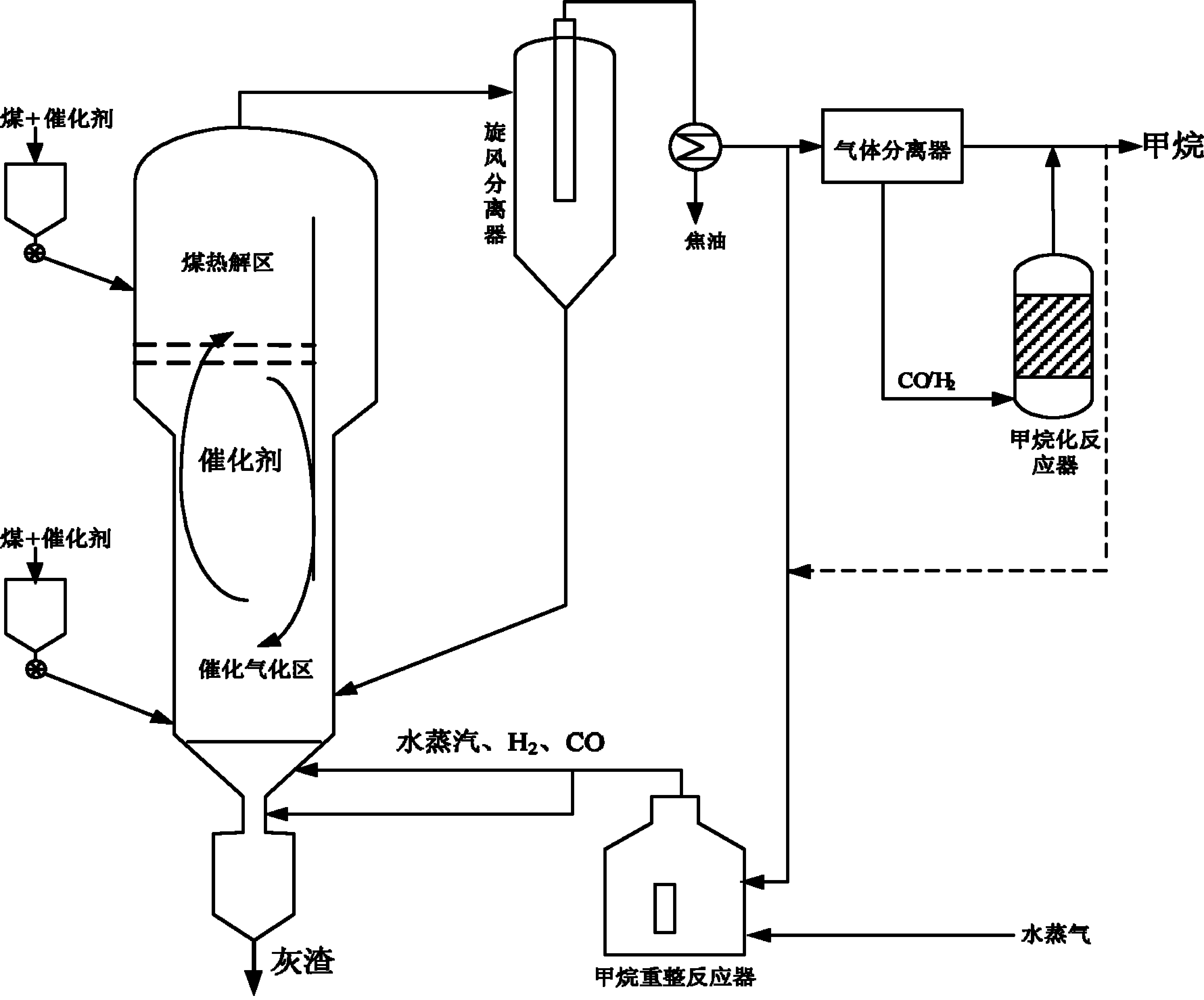

[0056] see figure 1 , which schematically shows a process flow diagram of a preferred embodiment of the present invention.

[0057] The selected coal is bituminous coal or lignite, the raw coal is crushed to a particle size of 0.1-2mm, and the alkali metal catalyst K 2 CO 3 It is wet mixed with coal powder at a weight ratio of 1:10. After drying, it is pressurized and enters the gasifier through a rotary feeder. The absolute pressure in the gasifier is 3.5MPa, and the gasification agent is reformed by methane. The temperature of the gasification agent is above 800°C. The gasification agent entering the gasifier: the weight ratio of coal is 2:1. The gasification agent enters the gasifier in two streams, and one enters from the distribution plate of the gasifier. The gasifier, another stream enters the gasifier from the center hole of the distribution plate of the gasifier, and the coal residue after coal gasification is smoothly discharged by controlling the operating gas vel...

Embodiment 2

[0061] still see figure 1 , the difference lies in the absolute pressure in the gasifier and the gasification agent: coal weight ratio.

[0062] The selected coal is bituminous coal or lignite, the raw coal is crushed to a particle size of 0.1-2mm, and the alkali metal catalyst K 2 CO 3 It is wet mixed with coal powder at a weight ratio of 1:10. After drying, it is pressurized and enters the gasifier through a rotary feeder. The absolute pressure in the gasifier is 0.1MPa, and the gasification agent is supplied by the methane reformer The temperature of the gasification agent is above 800°C, the gasification agent entering the gasifier: the weight ratio of coal is 1:1, the gasification agent enters the gasifier in two streams, and one enters the gasifier from the The other stream enters the gasifier from the center of the distribution plate of the gasifier, and the coal residue after coal gasification is smoothly discharged by controlling the operating gas velocity at the ce...

Embodiment 3

[0064] The basic process of this embodiment can be found in figure 1 , the difference is that the absolute pressure in the gasifier and the gasification agent: coal weight ratio are changed, and the methane-containing stream entering the methane reforming reactor is changed.

[0065] The selected coal is bituminous coal or lignite, the raw coal is crushed to a particle size of 0.1-2mm, and the alkali metal catalyst K 2 CO 3 It is wet mixed with coal powder at a weight ratio of 1:10. After drying, it is pressurized and enters the gasifier through a rotary feeder. The absolute pressure in the gasifier is 4.1MPa, and the gasification agent is supplied by the methane reformer The temperature of the gasification agent is above 800°C. The gasification agent entering the gasifier: the weight ratio of coal is 2.5:1. The gasification agent enters the gasifier in two streams. The other stream enters the gasifier from the center of the distribution plate of the gasifier, and the coal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com