Method for increasing yield of coal-pyrolysis-based tar in reaction atmosphere of methane-rich gas mixture in fluidized bed

A tar yield, fluidized bed technology, applied in the energy field, can solve problems such as low product yield, and achieve the effects of simple operation, large processing capacity, and reduced hydropyrolysis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

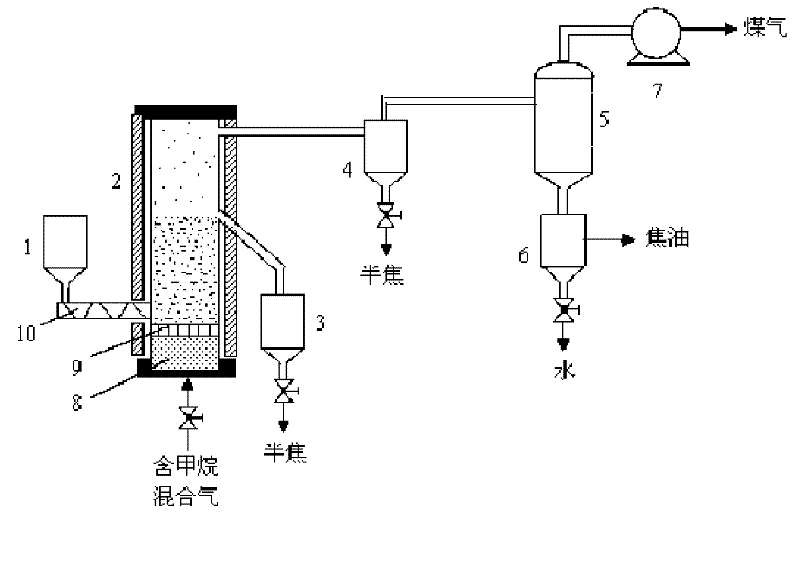

Method used

Image

Examples

Embodiment 1

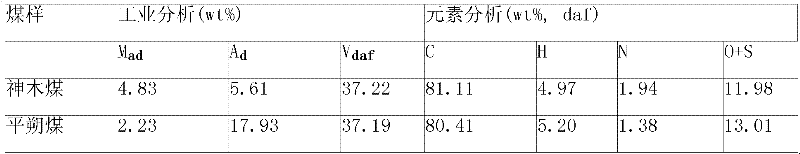

[0030]The selected coal is Shenmu coal, and its industrial analysis and elemental analysis are shown in Table 1. 5g of coal was used in the test, without catalyst, the pyrolysis conditions were temperature 750°C, constant temperature time 30min, pressure 0.1MPa, reaction gas was 800ml / min methane-containing mixed gas, the gas composition was shown in Table 2, and the tar yield obtained was 20.5wt % daf, semi-coke yield was 67.1wt% daf.

Embodiment 2

[0032] Select catalyst to be Ni / MgO catalyst, and its preparation method is: impregnate 10% (weight percent) Ni(NO 3 ) 2 6H 2 O, dried at 110°C for 12 hours, calcined at 800°C for 4 hours, pressed into tablets, screened out 20-40 mesh particles, and H at 850°C 2 -N 2 The mixture was restored for 4 hours.

[0033] The selected coal is Shenmu coal, and its industrial analysis and elemental analysis are shown in Table 1. The test used 5g of coal, 1g of catalyst, the pyrolysis conditions were temperature 750°C, constant temperature time 30min, pressure 0.1MPa, reaction gas was 800ml / min methane-containing mixed gas, the gas composition was shown in Table 2, and the tar yield obtained was 23.8wt % daf, semi-coke yield was 67.3wt% daf.

Embodiment 3

[0035] Select catalyst to be Ni / MgO catalyst, and its preparation method is: impregnate 10% (weight percent) Ni(NO 3 ) 2 6H 2 O, dried at 110°C for 12 hours, calcined at 800°C for 4 hours, pressed into tablets, screened out 20-40 mesh particles, and H at 850°C 2 -N 2 The mixture was restored for 4 hours.

[0036] The selected coal is Shenmu coal, and its industrial analysis and elemental analysis are shown in Table 1. The test used 5g of coal, 1g of catalyst, the pyrolysis conditions were temperature 750°C, constant temperature time 30min, pressure 0.1MPa, reaction gas 400ml / min methane-containing mixture, the gas composition is shown in Table 2, and the tar yield obtained was 21.6wt % daf, semi-coke yield was 65.3wt% daf.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com