Technique for preparing activated carbon with powdered coal pyrolysis powdered coke

A technology for preparing activated carbon and process methods, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as energy waste, environmental dust pollution, and rising production costs, and achieve improved consolidation strength and simple preparation processes , Increase the effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

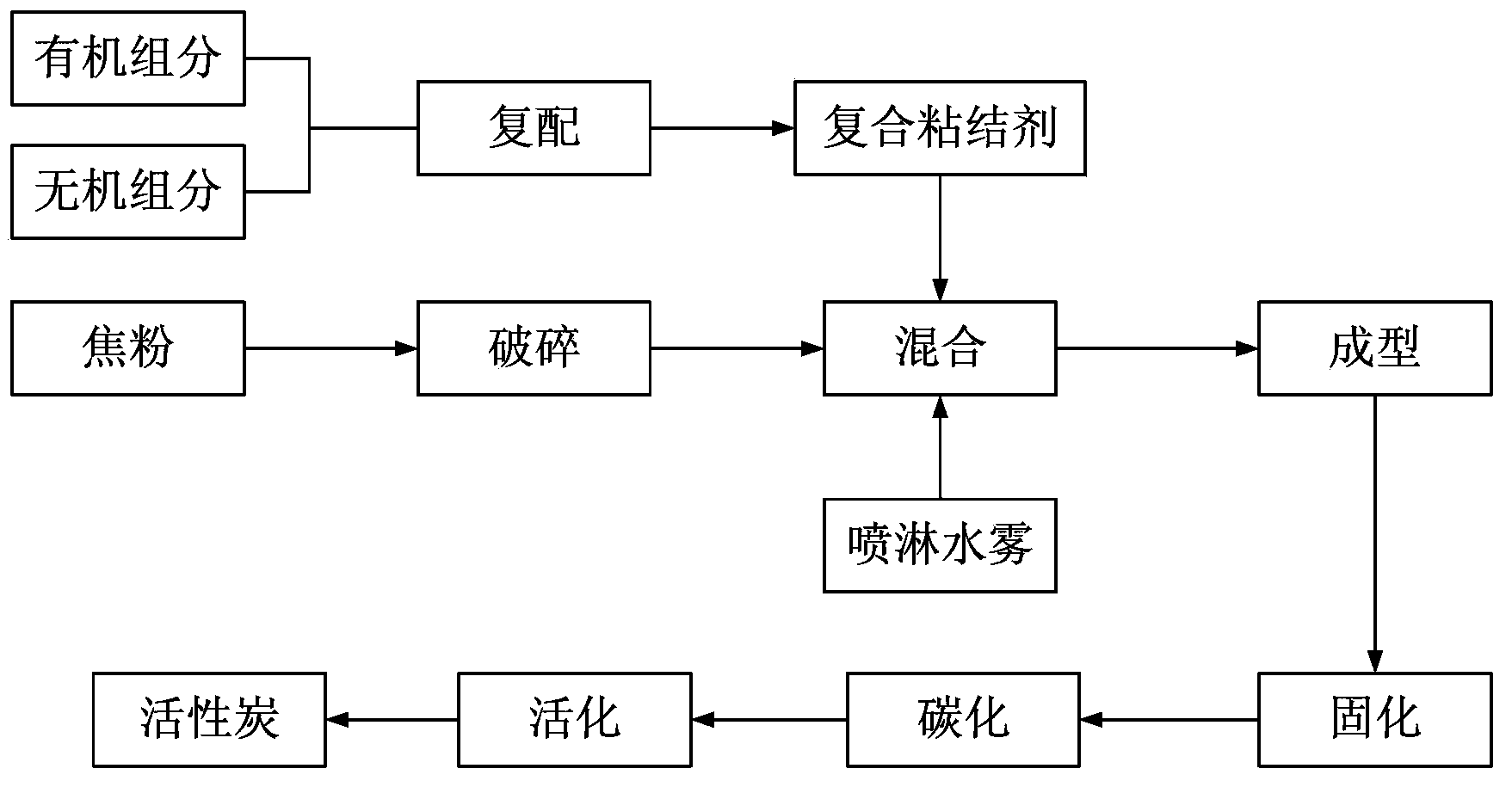

Method used

Image

Examples

Embodiment 1

[0043] Mix phenolic resin, medium-temperature coal tar pitch, water glass, and diatomaceous earth in a weight ratio of 30:60:6:4 to obtain a composite adhesive. Grind the coke powder to less than 0.5mm; sprinkle evenly the adhesive on the surface of the coke powder, stir in the mixer for 25 minutes, and spray an appropriate amount of water mist during the stirring process; : Mix evenly in a ratio of 5, send the evenly stirred coke powder and adhesive mixture into an extruder to prepare a cylinder with a diameter of 5mm and a length of 20mm, and place it at room temperature for curing for 30 hours; the cured product is carbonized at 800°C 3h, and further activated by passing water vapor in an activation furnace at 600°C for 3h to obtain a columnar activated carbon product.

Embodiment 2

[0045] First, prepare modified coal tar pitch: uniformly mix dibutyl phthalate, dioctyl phthalate, stearic acid and coal tar pitch in a weight ratio of 3:3:4:90 to obtain a modified coal tar pitch.

[0046] Then, mix polyvinyl alcohol, epoxy resin, modified coal tar pitch, water glass, cement, diatomaceous earth, and quicklime according to the ratio of 4:25:65:3:1:1:1 by weight to obtain a composite adhesive Adhesive. Grind the coke powder to 0.05mm; sprinkle evenly the binder on the surface of the coke powder, stir in the mixer for 35 minutes, spray an appropriate amount of water mist during the stirring process; the weight percentage of coke powder and binder is 92:8 Mix evenly, cold press the evenly stirred coke powder and binder mixture into a ball with a diameter of 10mm, and place it at room temperature for curing for 24 hours; after the cured product is carbonized at 600°C for 4 hours, it is further activated by KOH activation method The activation time in the furnace...

Embodiment 3

[0048] Mix polyvinyl acetal, hydroxymethyl cellulose, diatomaceous earth, and pottery clay uniformly in a weight ratio of 32:60:4:4 to obtain a composite adhesive. Crush the coke powder to the components between 0.1mm-0.5mm; sprinkle the adhesive evenly on the surface of the coke powder, stir in the mixer for 30min, and spray an appropriate amount of water mist during the stirring process; coke powder, bonding The agent is mixed evenly according to the ratio of 90:10 by weight, and the uniformly stirred coke powder and adhesive mixture are cold-pressed into a ball with a diameter of 12mm, and placed at room temperature for curing for 36h; the cured product is carbonized at 1000°C for 2h , using the KOH activation method to further pass water vapor into the activation furnace for activation at an activation temperature of 800 ° C for 1.5 h to obtain spherical activated carbon products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com