Method for treating waste incineration fly ash by using plasmas

A waste incineration fly ash and plasma technology, applied to the removal of solid waste, etc., can solve the problems of feeder jamming, pipeline blockage, fly ash bridging, etc., and achieve the effect of easy vitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

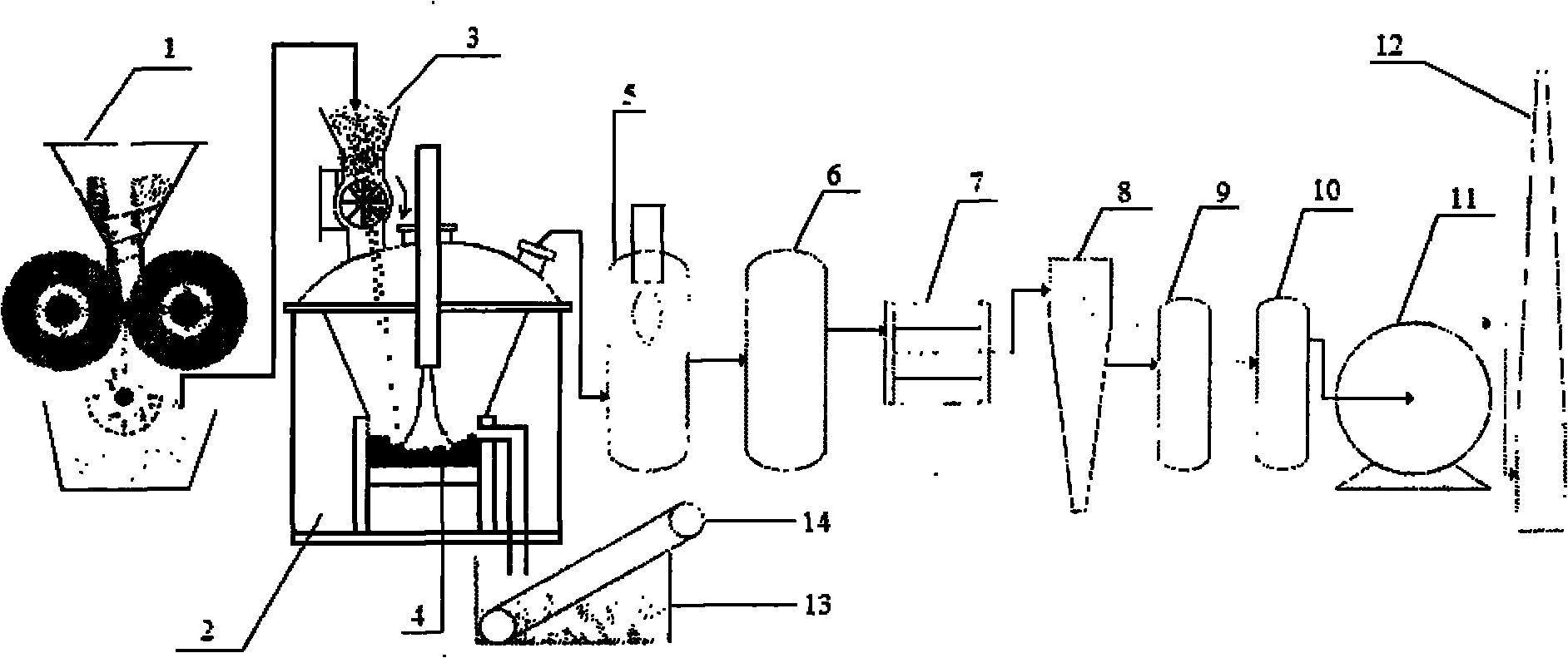

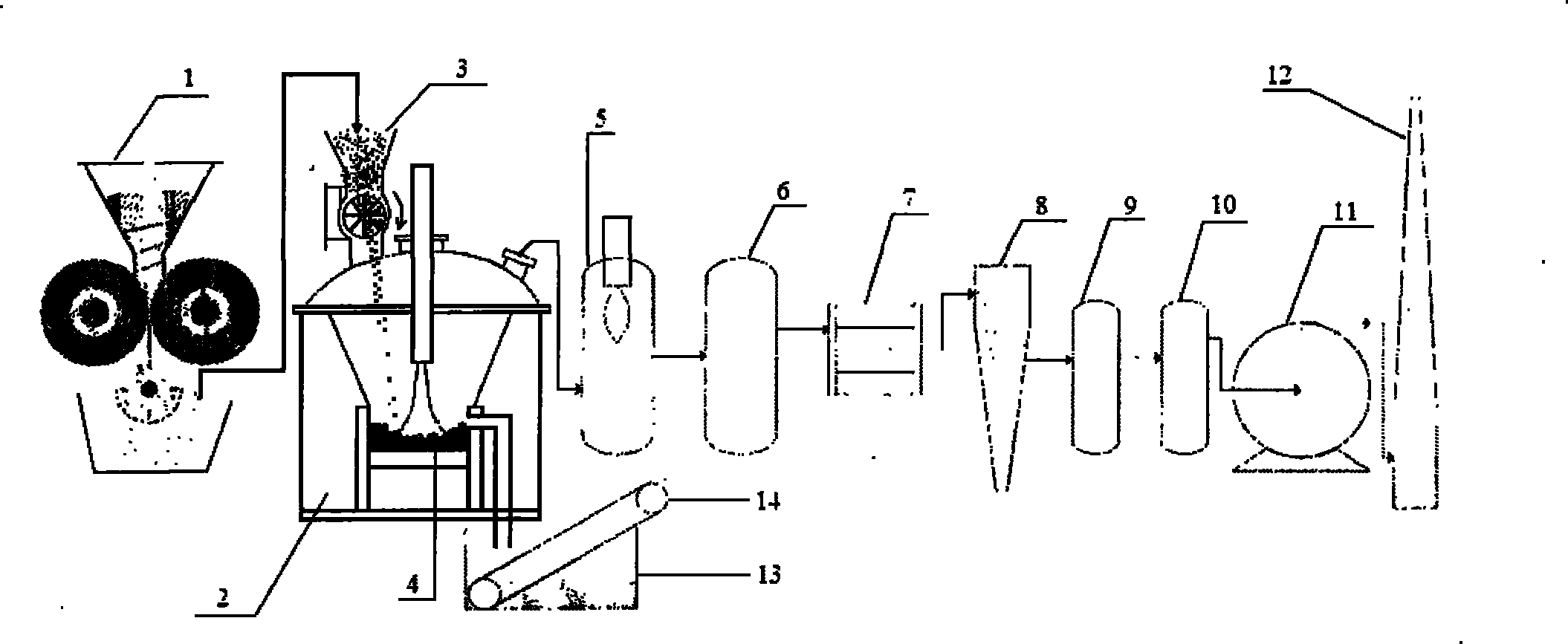

[0021] like figure 1 as shown,

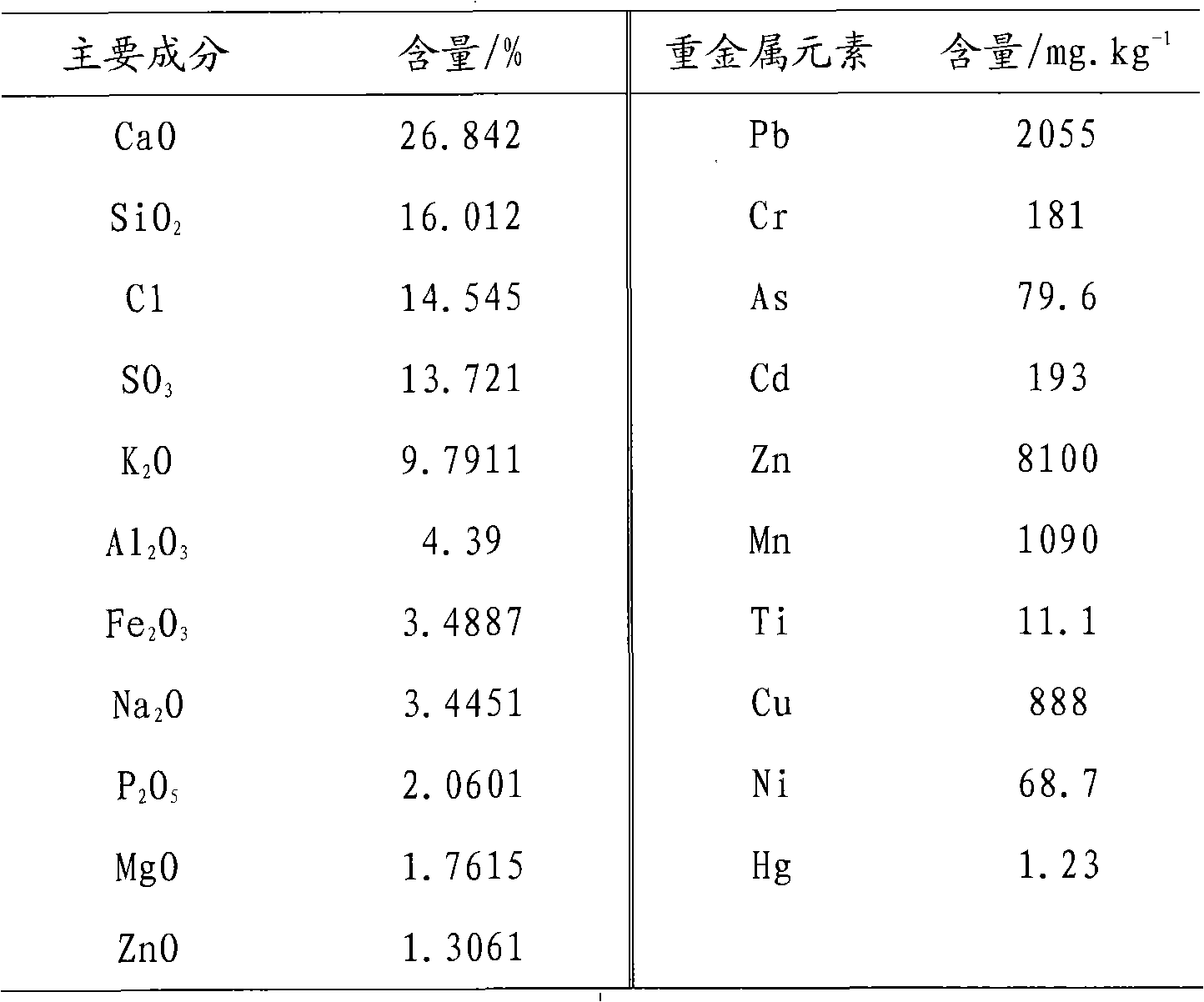

[0022] (1), by adding SiO 2 Regulation of CaO and SiO in waste incineration fly ash 2 The weight ratio is (0.25-3): 1, and then the adjusted incineration fly ash is transported into the granulator 1 for granulation or briquetting pretreatment;

[0023] (2), a molten metal pool is set in the plasma reaction furnace 2, metal is added in the molten metal pool, and the metal is heated to be melted;

[0024] (3), the top of the plasma reaction furnace 2 is provided with an opening, a feed hopper is installed above the opening, and a grid wheel 3 is installed in the feed hopper, and the grid wheel 3 is formed by a rotating shaft installed in the feed hopper and a rotating shaft installed on the rotating shaft. The waste incineration fly ash that has been granulated or compressed into blocks is continuously sent into the hopper, and the dividing wheel is continuously rotated to continuously transport the granulated or compressed waste incineration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com