A kind of glass composition and glass and its preparation method and application

A composition and glass technology, which is applied in the input/output process of instruments, data processing, calculation, etc., can solve the problems of anti-fluorescent stimulation, anti-scratch and wear-resistant performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In a second aspect, the present invention provides a glass preparation method, the method comprising: sequentially mixing, melting, homogenizing, casting and annealing the above composition for glass.

[0046] According to the method of the present invention, the melting can be carried out in a platinum-rhodium crucible. Preferably, the melting conditions include: the temperature is 1450-1580° C., and the time is 4-10 hours. Those skilled in the art can determine the specific melting temperature and melting time according to the actual situation, which are well known to those skilled in the art, and will not be repeated here.

[0047] According to the method of the present invention, the homogenization is a conventional homogenization method in the art, for example, the gas bubbles in the molten glass can escape by stirring and the components in the molten glass are evenly distributed.

[0048] According to the method of the present invention, the pouring molding is a c...

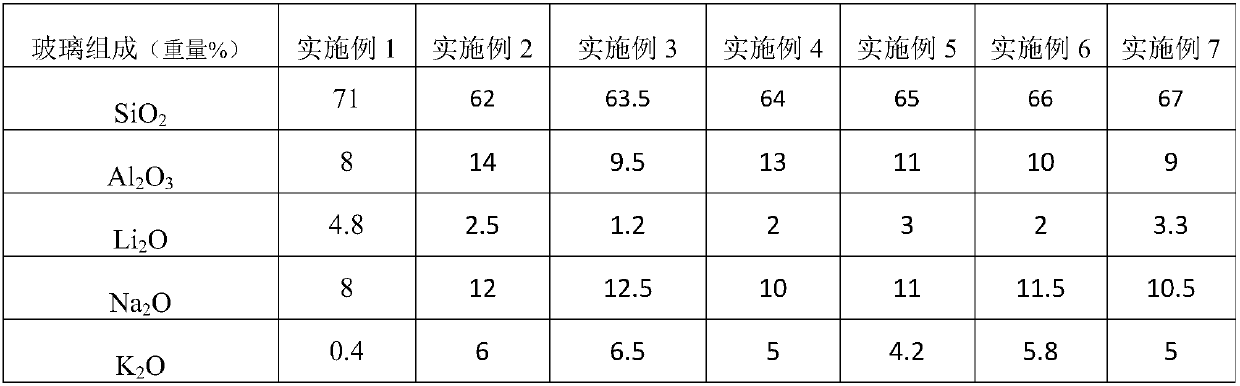

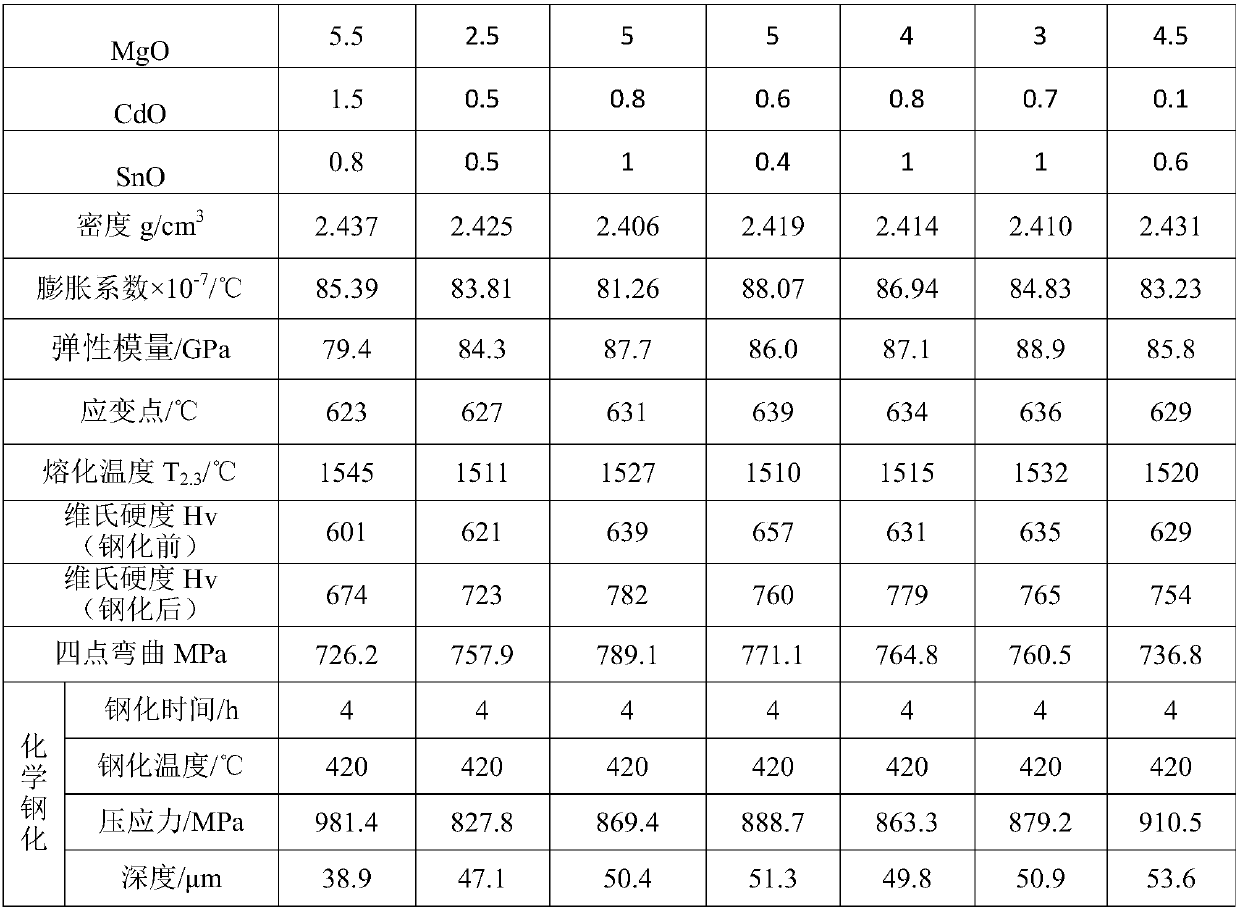

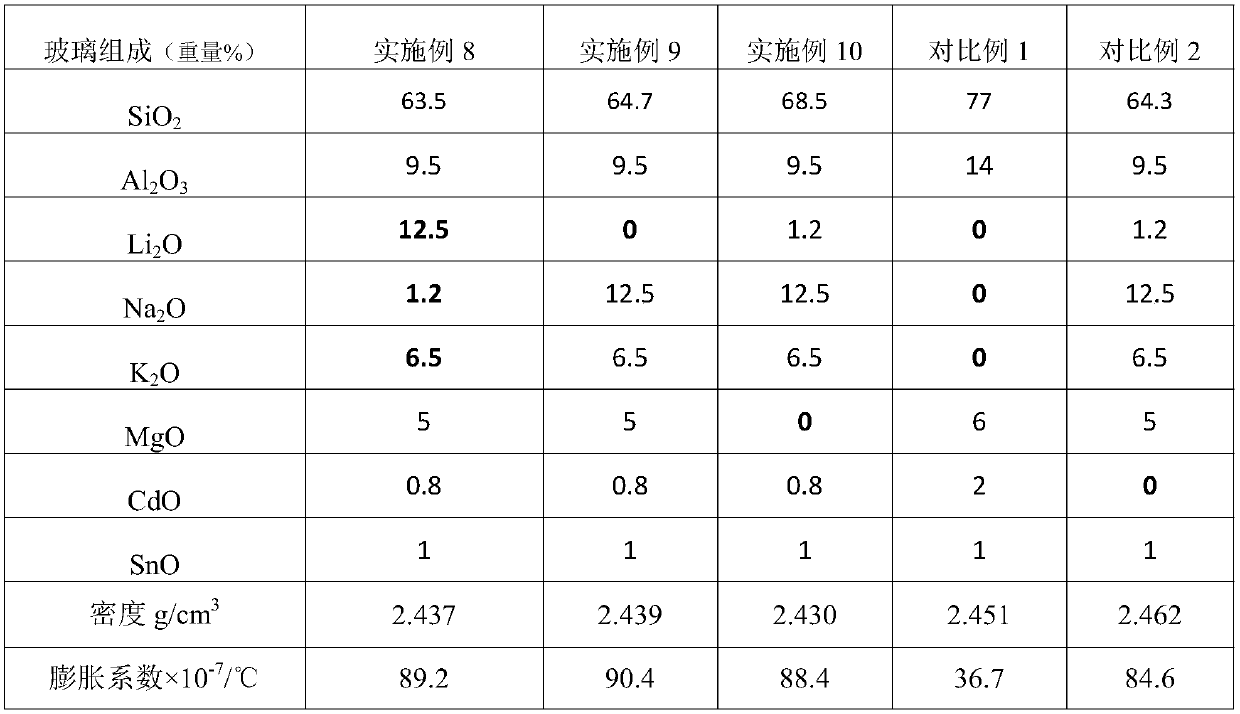

Embodiment 1-10 and comparative example 1-2

[0068] Weigh each component as shown in Tables 1 and 2, mix well, pour the mixture into a platinum-rhodium crucible, then heat in a resistance furnace at 1500°C for 6 hours, and stir with a platinum rod to remove air bubbles. The molten glass is poured into a stainless steel cast iron mold to form a specified block glass product, and then the glass product is annealed in an annealing furnace at 600°C for 2 hours, then the power is turned off and the furnace is cooled to 25°C. The glass product is sliced, ground and polished, then cleaned with deionized water and dried to obtain a finished glass product, which is chemically tempered before testing. Various properties of each glass product were measured respectively, and the results are shown in Tables 1 and 2.

[0069] Table 1

[0070]

[0071]

[0072] Table 2

[0073]

[0074]

[0075] By comparing the data in tables 1 and 2, it can be known that the coefficient of expansion of the glass prepared by the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com