Milk and dairy food containing fruit granules and method for producing the same

A production method and technology of dairy products, applied in dairy products, milk preparations, applications, etc., can solve problems such as inconsistent product quality, short effective time of action, short shelf life, etc., to achieve suspension stability, cholesterol-free, avoid cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: the milk beverage preparation formula (in 1 ton) containing coconut milk fermented polysaccharide granules and fresh pineapple granules:

[0059] Milk: 500 kg, white sugar: 50 kg, aspartame: 0.1 kg, acesulfame potassium: 0.1 kg citric acid: 2.0 kg, lactic acid: 2.4 kg, modified bio-fermented polysaccharide: 0.5 kg, carboxymethyl cellulose Sodium: 3.0 kg, coconut juice fermented polysaccharide granules: 40.0 kg, fresh pineapple granules: 30 kg pineapple essence: 0.5 kg, purified water: 371.4 kg

[0060] Raw material standard:

[0061] Milk: protein ≥ 2.90%, fat ≥ 3.0%

[0062] White sugar, aspartame, acesulfame potassium, citric acid, lactic acid, guar gum, and sodium carboxymethylcellulose meet relevant national standards;

[0063] The modified bio-fermentation polysaccharide is gellan gum;

[0064] Coconut milk fermented polysaccharide particle length is 7mm, specific gravity is 1.02g / cm 3 ; It consists of sugar liquid and pineapple coconut juice ferm...

Embodiment 2

[0084] Embodiment 2: the milk drink preparation that contains coconut milk fermented polysaccharide granule and fresh aloe vera granule

[0085] According to the method with embodiment 1, difference is:

[0086] Formula (according to 1 ton):

[0087] Milk: 360 kg, white sugar: 60 kg, fructose syrup: 40 kg, citric acid: 2.5 kg, lactic acid: 1.5 kg, modified bio-fermented polysaccharide: 0.3 kg, pectin: 1.0 kg, sodium carboxymethyl cellulose : 2.5 kg, coconut juice fermented polysaccharide granules: 100 kg, fresh aloe vera granules: 80 kg, aloe essence: 0.3 kg, purified water: 451.9 kg

[0088] Raw material standard:

[0089] Milk: protein ≥ 2.90%, fat ≥ 3.0%

[0090] White sugar, fructose syrup, citric acid, lactic acid, pectin, and sodium carboxymethylcellulose meet relevant national standards;

[0091] The modified bio-fermentation polysaccharide is xanthan gum;

[0092] Aloe vera particles and coconut juice fermented polysaccharide particles are cubes with a particle si...

Embodiment 3

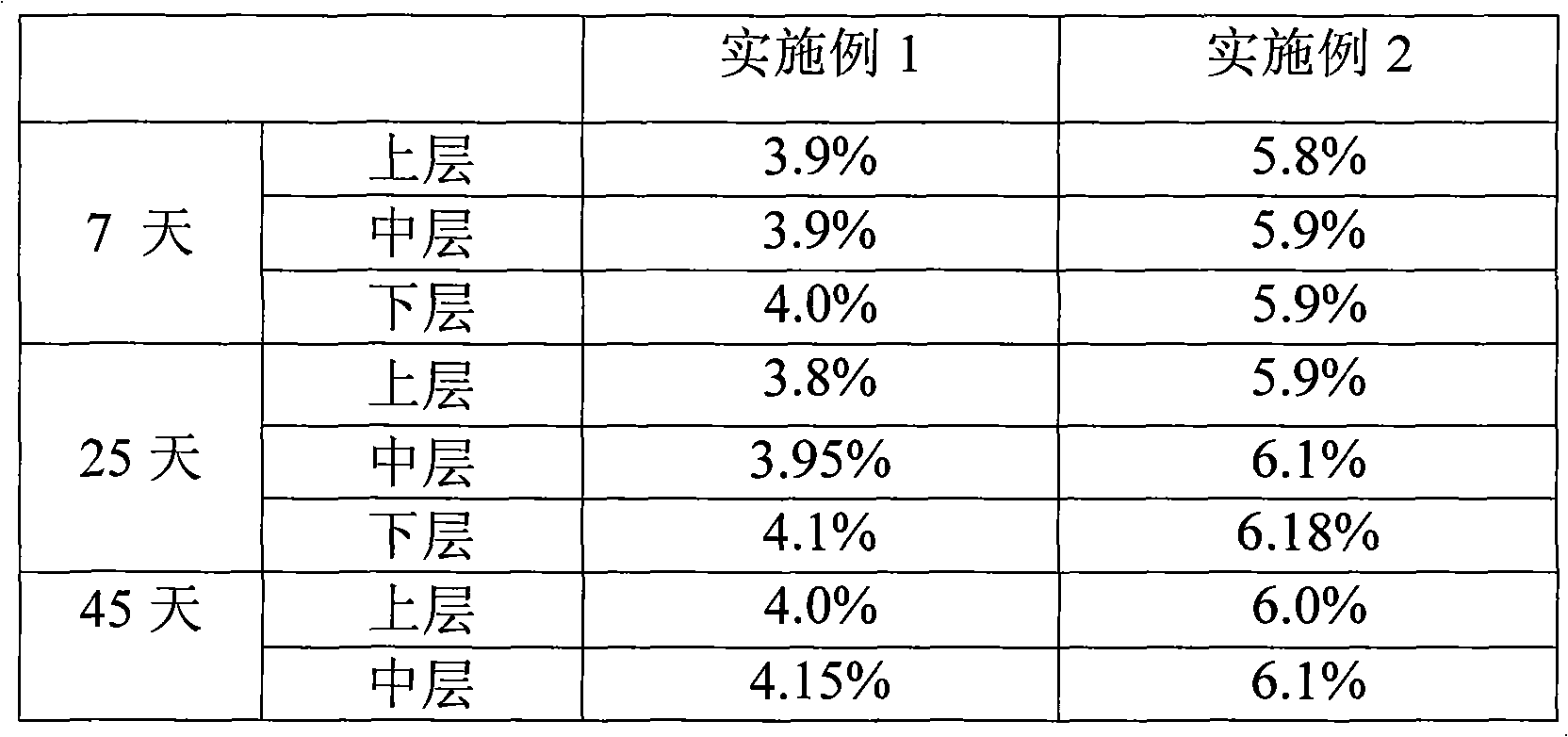

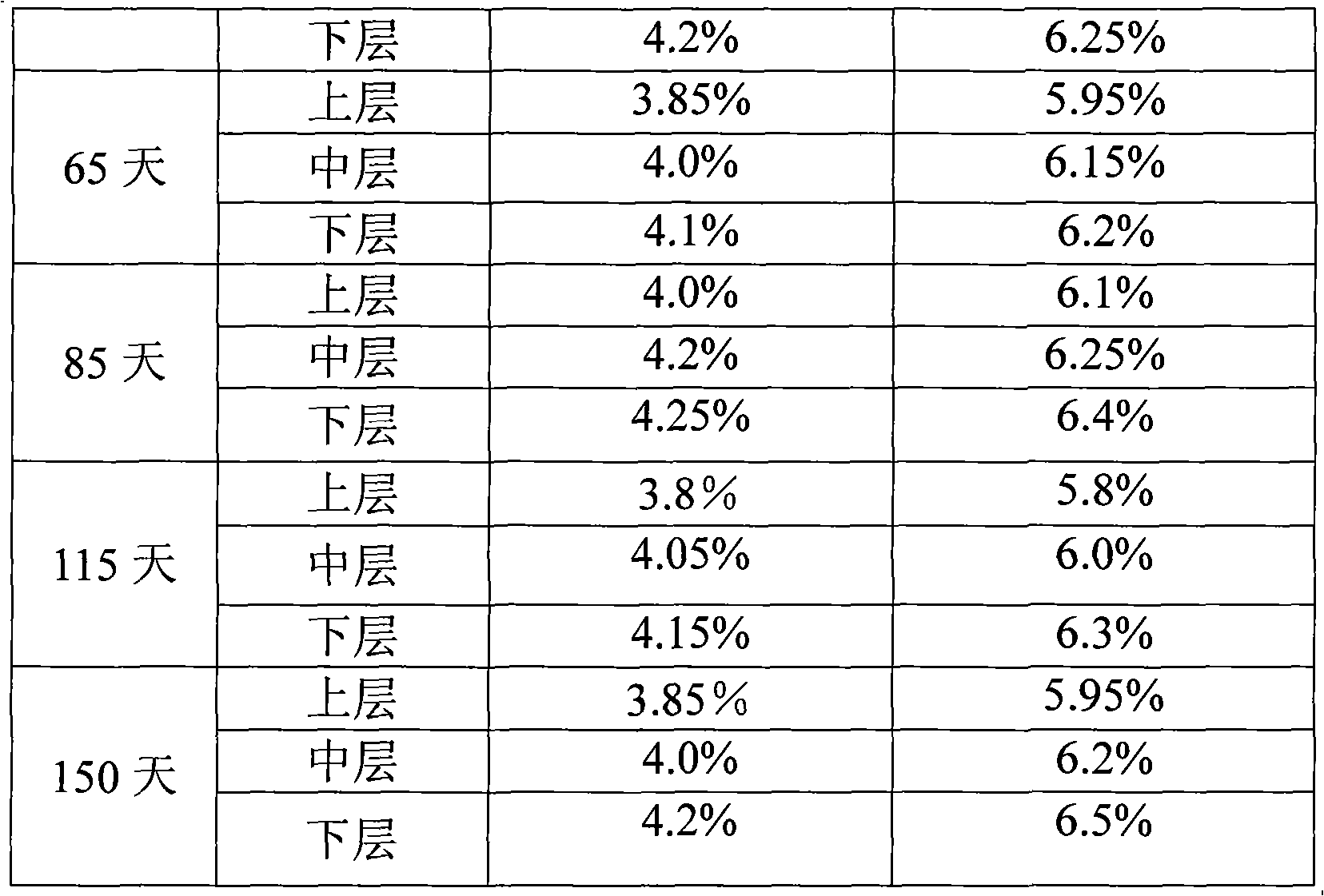

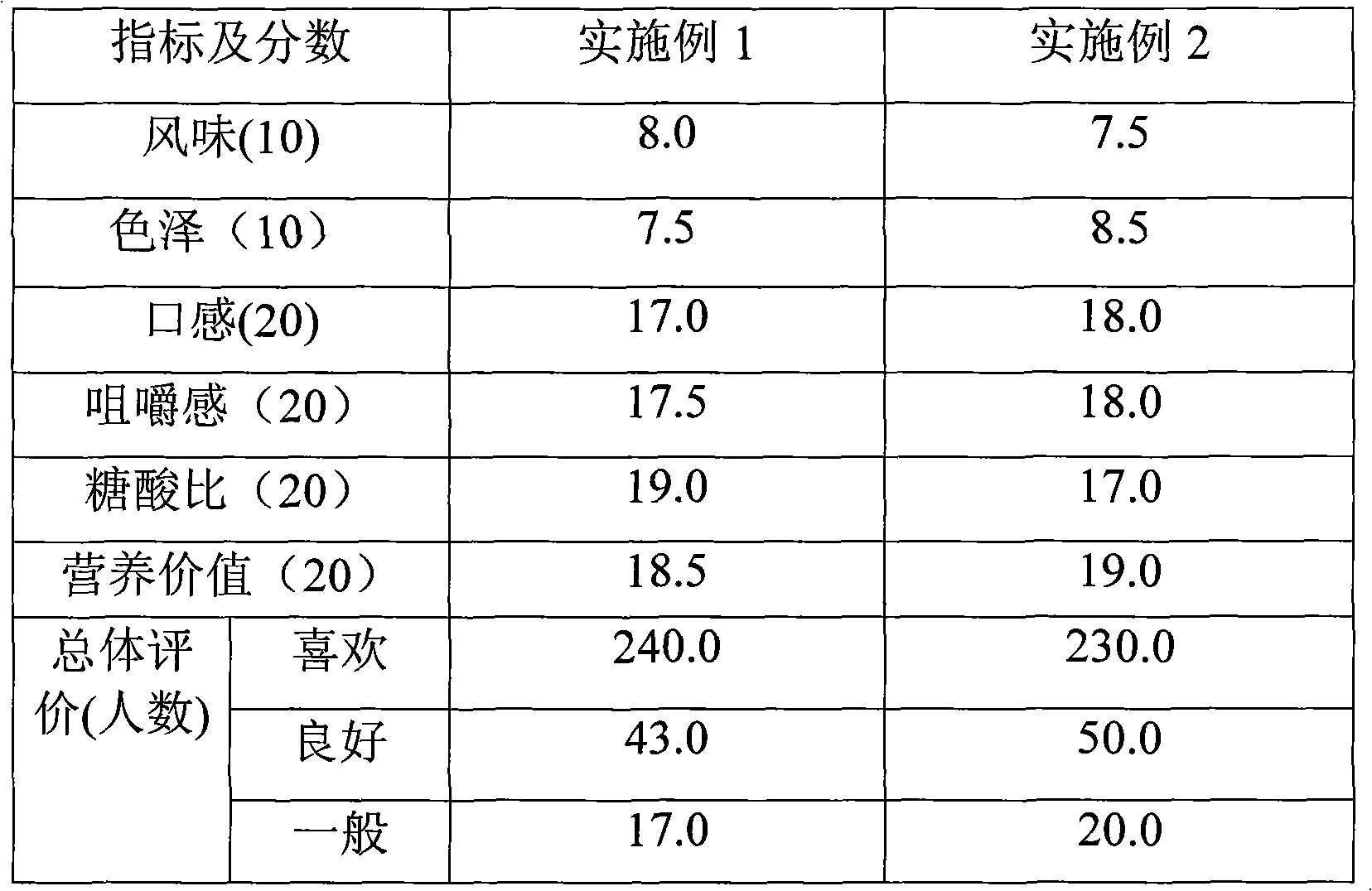

[0096] Embodiment 3: product quality analysis

[0097] Product quality analysis mainly includes comprehensive evaluation of protein stability, polysaccharide particles fermented with coconut milk (or fruit and vegetable particles) suspension, product taste and product microorganisms. Ordinary dairy products containing fruit pieces were used as a comparison sample.

[0098]1) Evaluation of protein stability: mainly expressed by sensory evaluation and centrifugal sedimentation rate. Since the specific gravity of protein is greater than that of water and fat, under a certain centrifugal force, protein sinks to the bottom of the centrifuge tube. The centrifuge sedimentation rate refers to the ratio of the sedimentation amount to the total sample. The larger the ratio, the more life-threatening protein precipitation, and the poor product stability. Centrifugal force 5000g. The experimental records are shown in Table 1.

[0099] 2) Suspension of fruit particles: Static observati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com