Systems and methods of producing a crude product

a technology of crude feed and system, applied in the direction of fuels, physical/chemical process catalysts, products, etc., can solve the problems of difficult and expensive transportation and/or processing of crude using conventional facilities, difficult water removal of less viscous crude and/or crude mixtures using conventional means, and disadvantaged crudes often contain relatively high residue levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0286] Preparation of a K—Fe Sulfide Catalyst. A K—Fe sulfide catalyst was prepared by combining 1000 grams of iron oxide (Fe2O3) and 580 g of potassium carbonate with 412 grams of de-ionized water to form a wet paste. The wet paste was dried at 200° C. to form an iron oxide / potassium carbonate mixture. The iron oxide / potassium carbonate mixture was calcined at 500° C. to form an iron oxide / potassium carbonate mixture. The iron oxide / potassium carbonate mixture was reacted with hydrogen to form a reduced intermediate solid that included iron metal. Hydrogen addition was performed over 48 hours at 450° C. and 11.5-12.2 MPa (about 1665-1765 psi). The intermediate solid was passed through a 40-mesh sieve with minimal force.

[0287] The intermediate solid was added incrementally at a rate to control the evolution of heat and produced gas to a VGO / m-xylene / elemental sulfur mixture at 100° C. After addition of the intermediate solid, the resulting mixture was incrementally heated to 300° C...

example 2

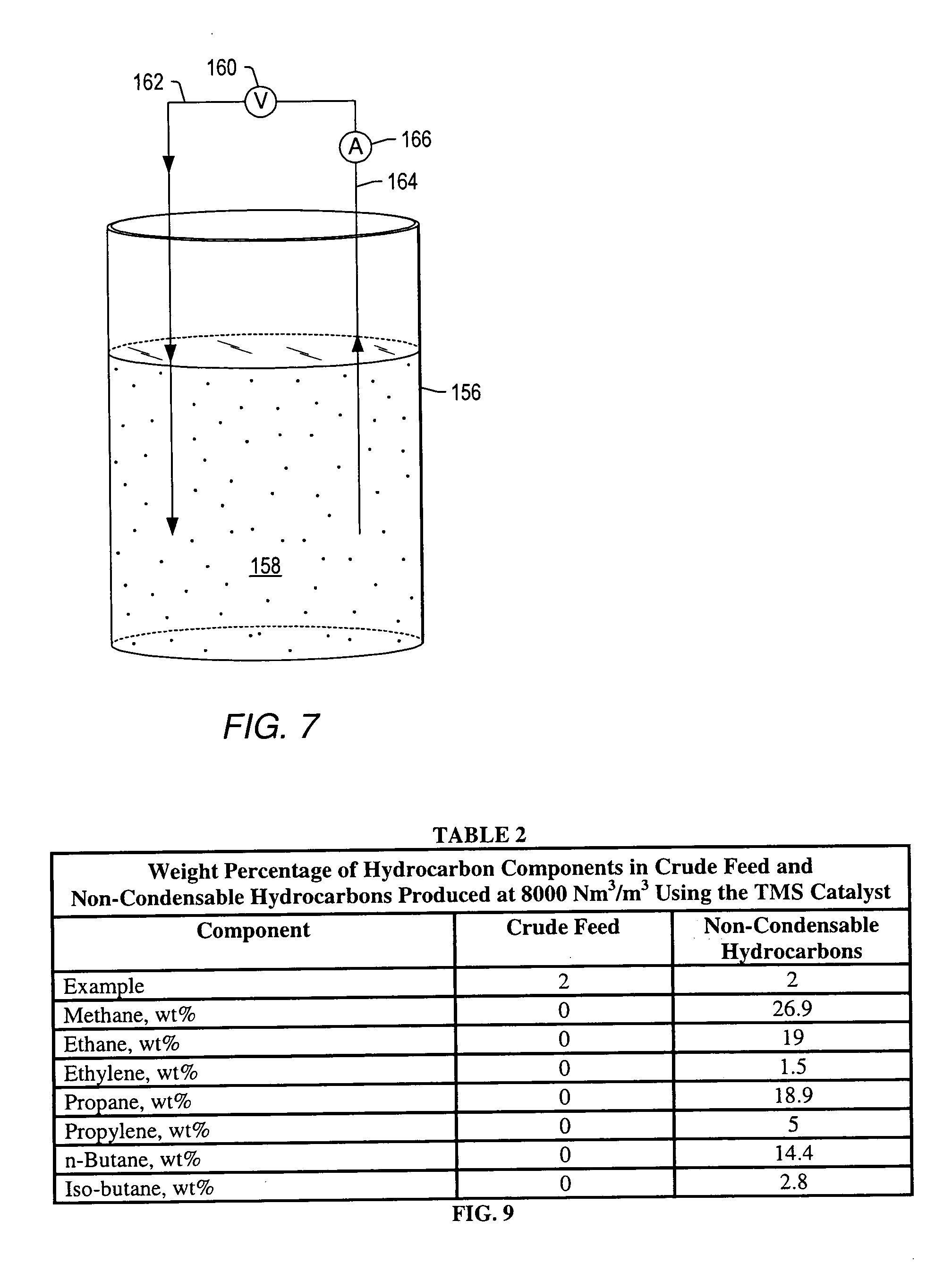

[0289] Contact of a Crude Feed With a Hydrogen Source in the Presence of a K—Fe Sulfide Catalyst. A 600 mL continuously stirred tank reactor (composed of 316 stainless steel) was fitted with a bottom inlet feed port, a single vapor effluent port, three thermocouples located in the reactor interior, and a shaftdriven 1.25-inch diameter six-blade Rushton turbine.

[0290] The K—Fe sulfide catalyst (110.3 grams) prepared as described in Example 1 was charged to the reactor. Hydrogen gas was metered at about 8,000 Nm3 / m3 (50,000 SCFB) into the reactor and mixed with bitumen (Lloydminster region of Canada). The bitumen entered the reactor through the bottom inlet feed port to form a hydrogen / crude feed mixture. During the reaction run period of about 185 hours, hydrogen gas and crude feed were continuously fed into the reactor and product was continuously removed through the effluent vapor port of the reactor. Crude feed was fed at a rate of 67.0 g / hr to maintain the crude feed liquid leve...

example 3

[0301] Preparation of a K—Fe Sulfide Catalyst in the Absence of Hydrocarbon Diluent. A K—Fe sulfide catalyst was prepared by combining 1000 g of iron oxide and 173 g of potassium carbonate with 423 g of de-ionized water to form a wet paste. The wet paste was processed as described in Example 1 to form the intermediate solid. The intermediate solid was passed through a 40-mesh sieve with minimal force.

[0302] In contrast to Example 2, the intermediate solid was mixed with elemental sulfur in the absence of a hydrocarbon diluent. In a dry-box using an argon atmosphere, the intermediate solid was mixed with powdered elemental sulfur, placed in a sealed carbon steel cylinder, heated to 400° C., and maintained at 400° C. for about 1 hour. The sulfurized catalyst was recovered from the carbon steel reactor as a solid. The potassium-iron sulfide catalyst was crushed to a powder using a mortar and pestle such that the resulting catalyst powder passed through a 40-mesh sieve.

[0303] The resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com