Hard armor composite

a composite material and hard armor technology, applied in the field of hard armor composites, can solve the problem that the ceramic armor is configured for a fixed level of protection, and achieve the effect of low denier-per-filament (dpf) fibers and high performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

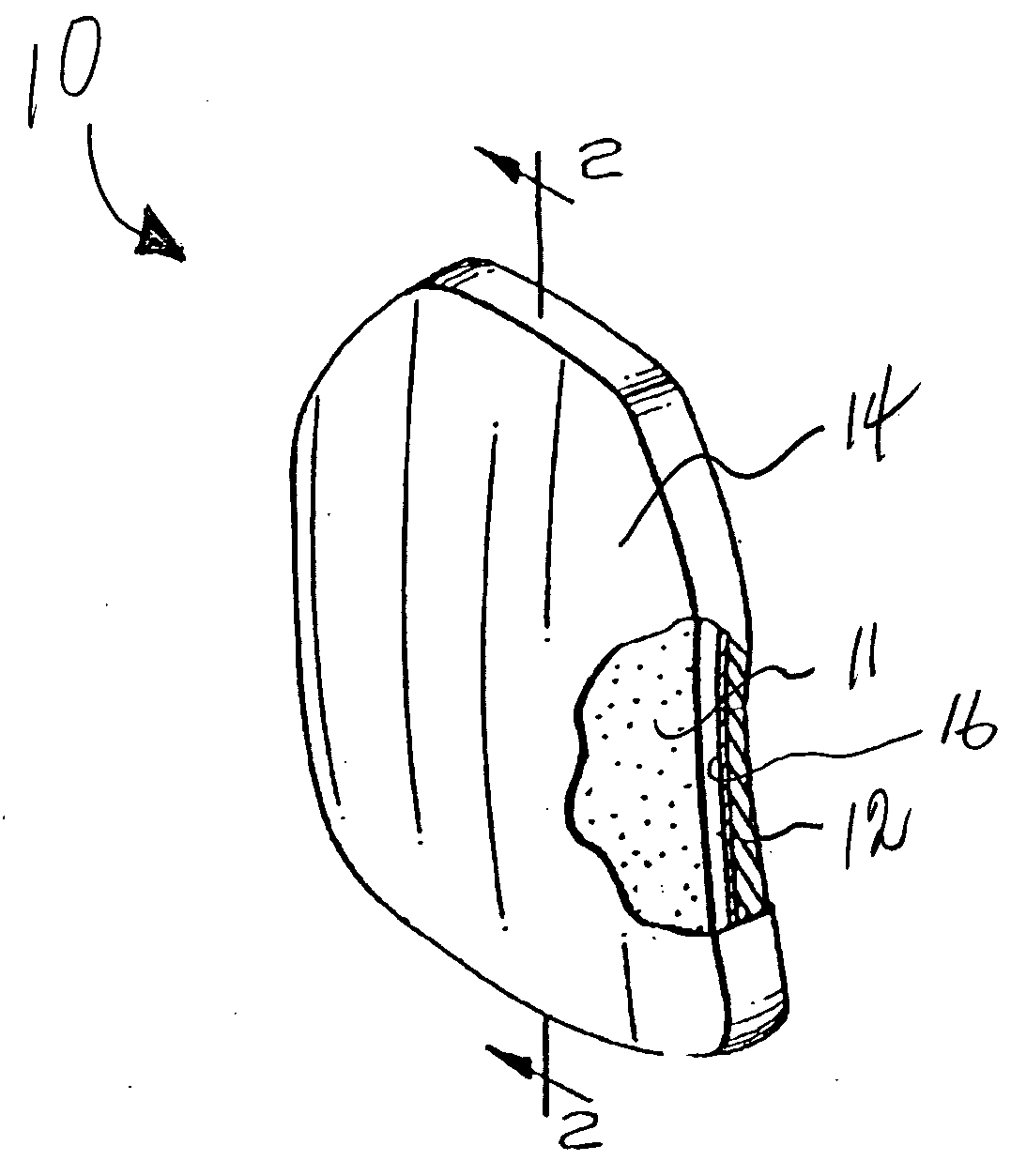

[0035] Referring now specifically to the drawings, a hard armor composite according to the present invention is illustrated in FIG. 1, and shown generally at reference numeral 10. In one application, the composite 10 is a small arms protection insert (SAPI) designed to protect against multiple small arms bullets and projectiles. The composite 10 is constructed according to United States military specifications, CO / PD 00-03D dated Jan. 13, 2003, in sizes X-small, small, medium, large, and X-large ranging in weight from 2.85 to 5.35 pounds. All SAPI sizes have a uniform nominal areal density of 5.1 pounds per square foot or less. The dimensional measurements are indicated in Drawing Nos. 2-6-265, 2-6-266, 2-6-267, 2-6-268, and 2-6-269 of CO / PD 00-03D. The entire subject matter of CO / PD 00-03D, including text, drawings, tables, and charts, is incorporated herein by reference.

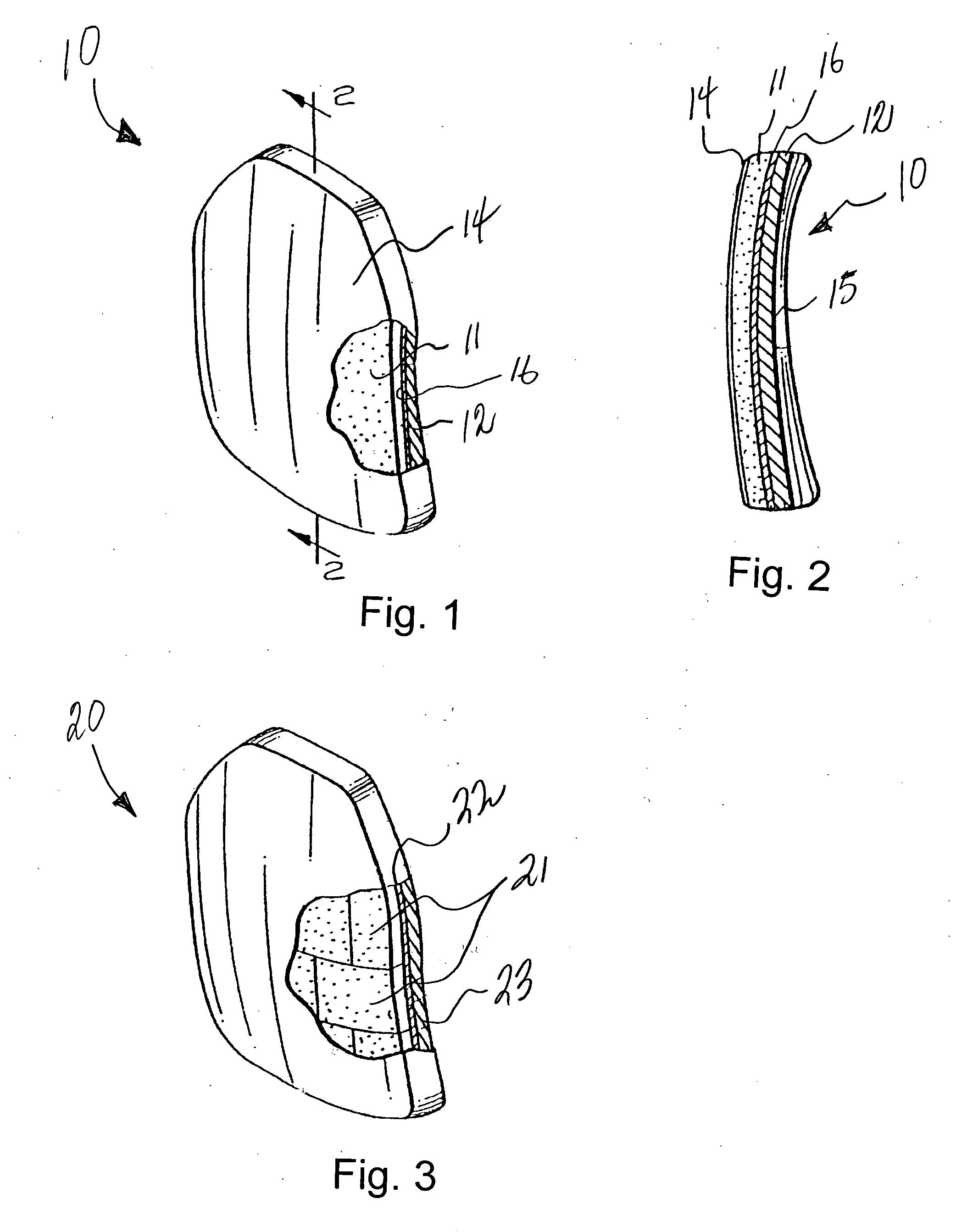

[0036] As shown in FIGS. 1 and 2, the hard armor composite (SAPI) 10 comprises a ceramic plate 11 and ballistic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com