Wear adjustment device of a disc brake and corresponding disc brake

A technology of disc brakes and adjustment devices, applied in the direction of brake parts, brakes, brake types, etc., to achieve the effect of reducing the number of components, saving space, and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

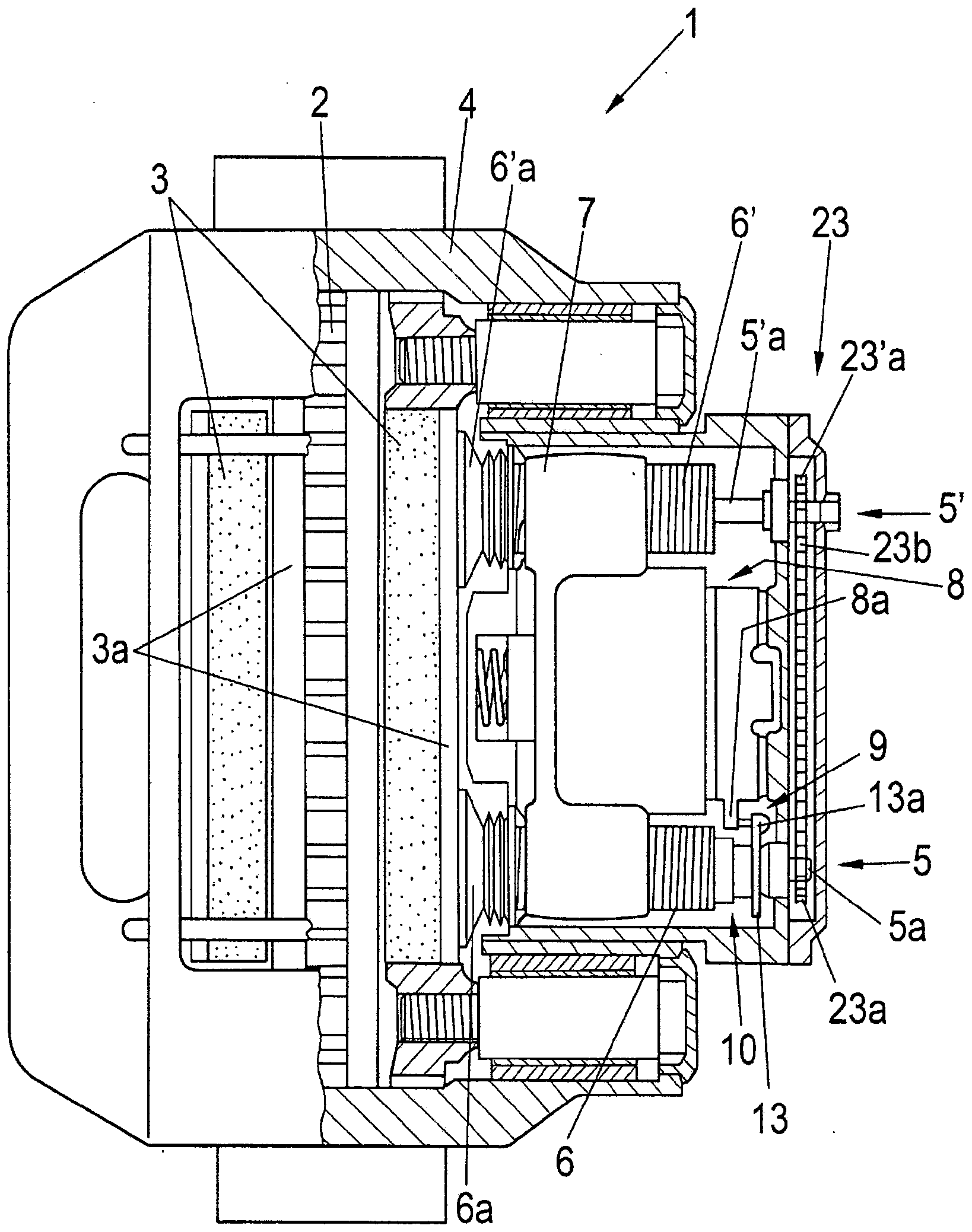

[0048] figure 1 A schematic sectional view of an embodiment of a disc brake according to the invention is shown.

[0049]The disc brake 1 is shown here in the embodiment of a double-rod brake comprising two screw units 5 , 5 ′ with threaded tubes 6 , 6 ′. The brake caliper 4 , designed here as a floating caliper, straddles the brake disk 2 , on which a brake lining 3 with a brake lining carrier 3 a is provided on both sides. The pressure-side brake lining carrier 3 a is connected to the screw unit 5 , 5 ′ at the end of the threaded tube 6 , 6 ′ via a pressure plate 6 a , 6 ′ a. The other brake lining carrier 3 a on the reactive side is fastened in the brake caliper 4 on the other side of the brake disc. The threaded pipes 6 , 6 ′ are respectively rotatably arranged in the cross member 7 . This crosspiece 7 and thus also the threaded tubes 6 , 6 ′ can be actuated by means of a pressing device, here a swivel lever 8 , the axis of rotation of which is perpendicular to the axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com