Compact, flexible csp installation for continuous, semi-continuous and batch operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

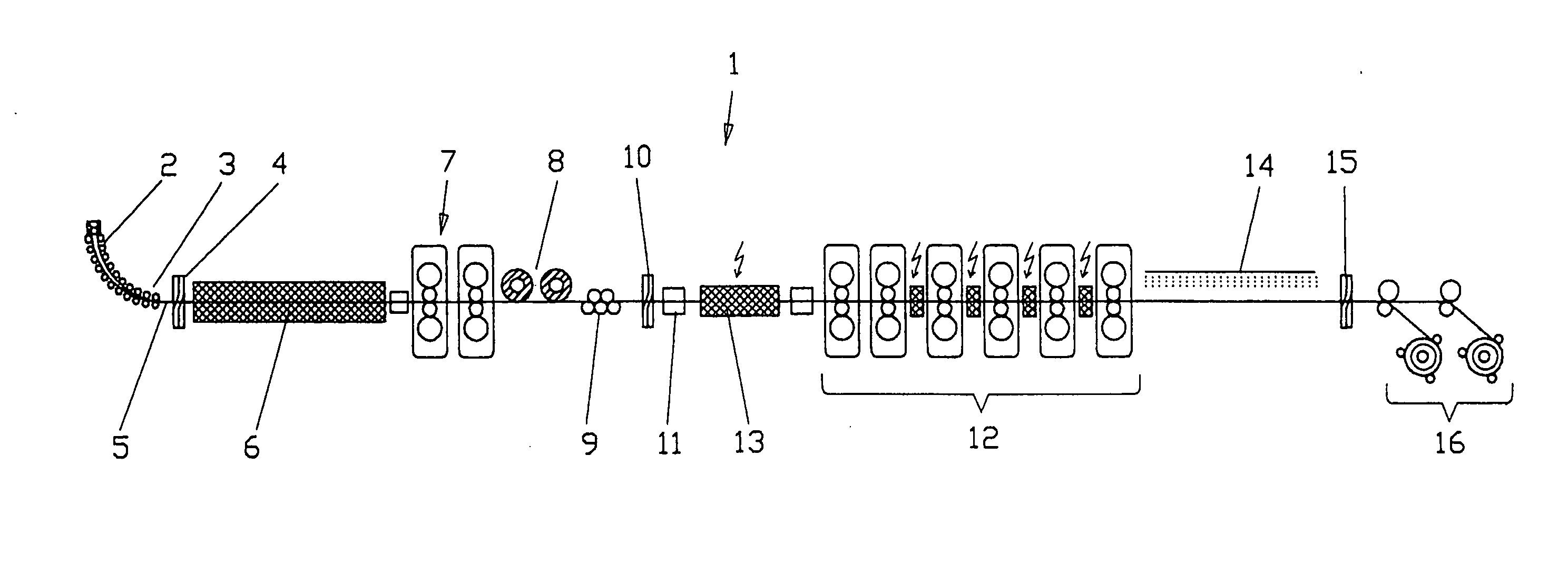

[0029]FIG. 1 shows a diagrammatic illustration of a compact, flexible CSP installation 1 for endless, semi-endless and batch operation. The installation 1 has here a casting machine 2 with a caster outlet 3. After the caster outlet 3, a cutter 4 is provided, in order to be able to cut the strand 5 emerging out from the caster outlet 3. After the cutter 4, a furnace 6 is provided, such as preferably a tunnel furnace, which heats the strand 5 up to the desired temperature. The furnace 6 is therefore arranged between the caster outlet 3 and the cutter 4 on the one hand and the subsequent roughing stand group 7 on the other hand. In the example embodiment of FIG. 1, the roughing stand group 7 has two roughing stands. However, according to another idea in accordance with the invention, the roughing stand group 7 may also have one or three roughing stands. In this example embodiment, after the roughing stand group 7 a so-called coil store 8 is provided for the strand material, in order to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thermal properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com