Effective method to improve sub-micron color filter sensitivity

a color filter and effective technology, applied in the field of solid-state imaging devices, can solve the problems of image quality decline, long focal length is a big challenge to maintaining adequate sensor sensitivity, and the size and oval shape of the microlens can be difficult to reproduce, so as to achieve the effect of improving sensitivity and long focal length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

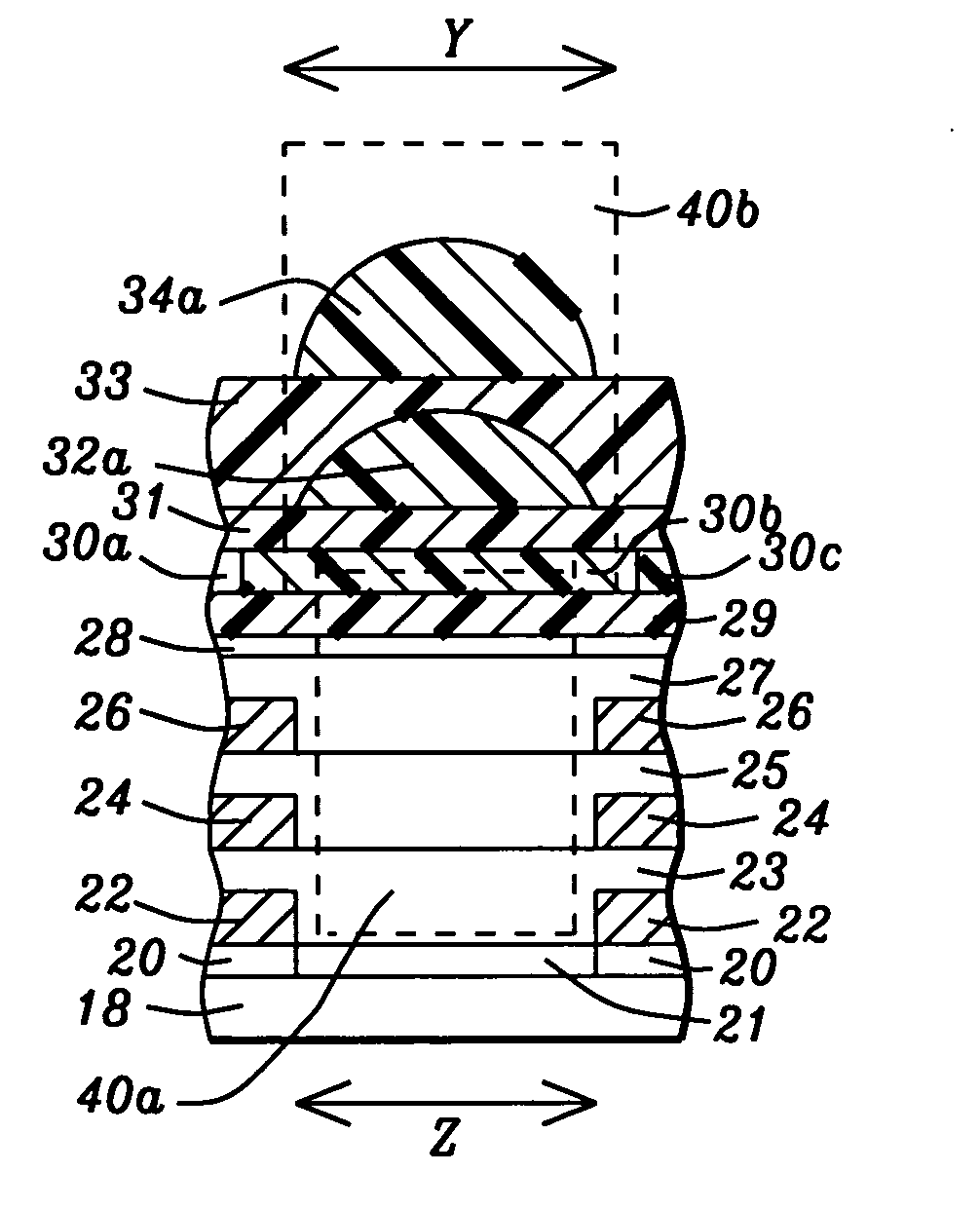

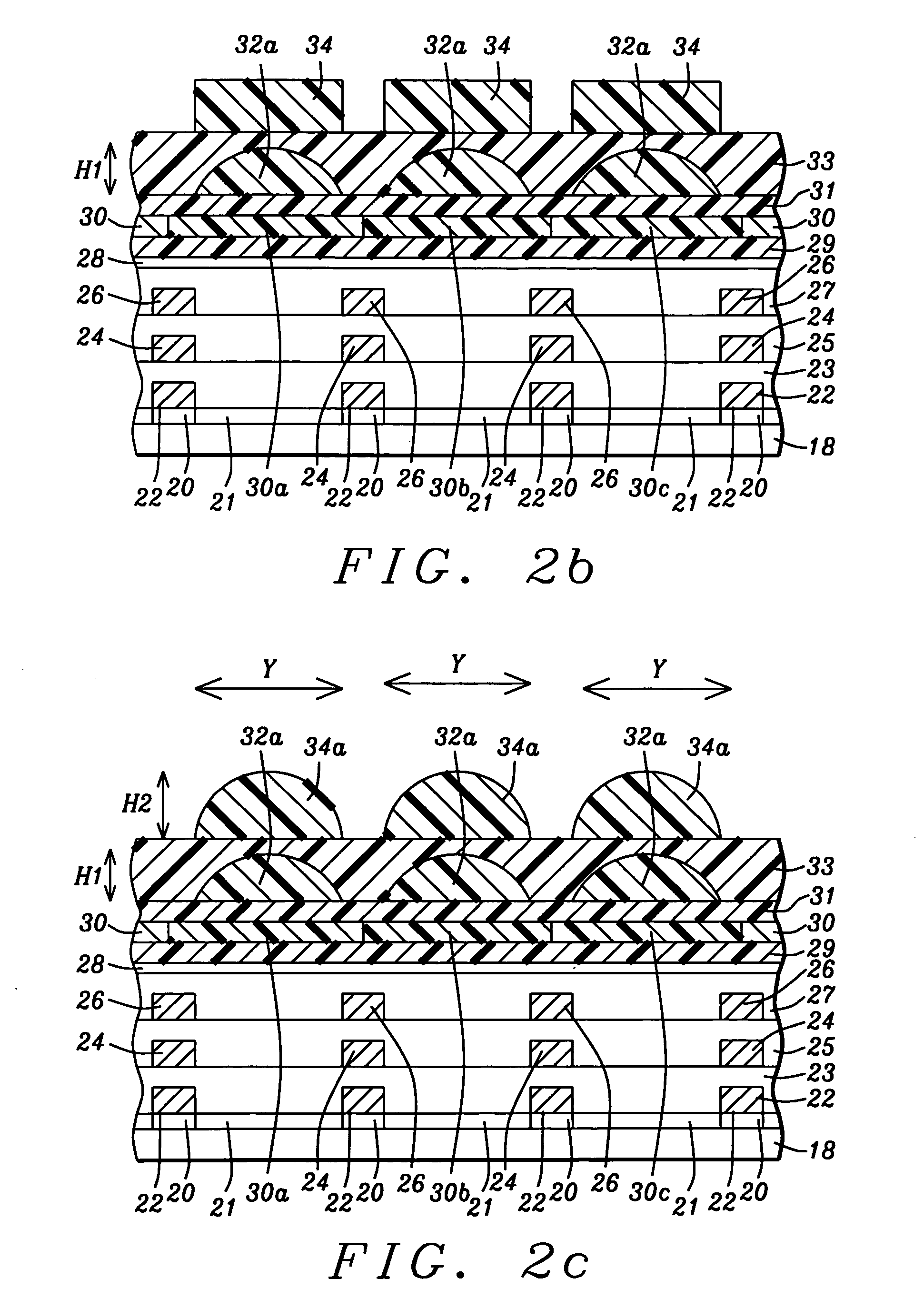

[0021] The present invention is a microlens component of a CMOS image sensor that provides improved sensitivity for sub-micron devices that have a pixel size of less than 5 microns. A process is also described for forming the improved CMOS image sensor. The drawings are provided by way of example and are not intended to limit the scope of the invention. Furthermore, the relative sizes of the various elements within the drawings are not necessarily drawn to size.

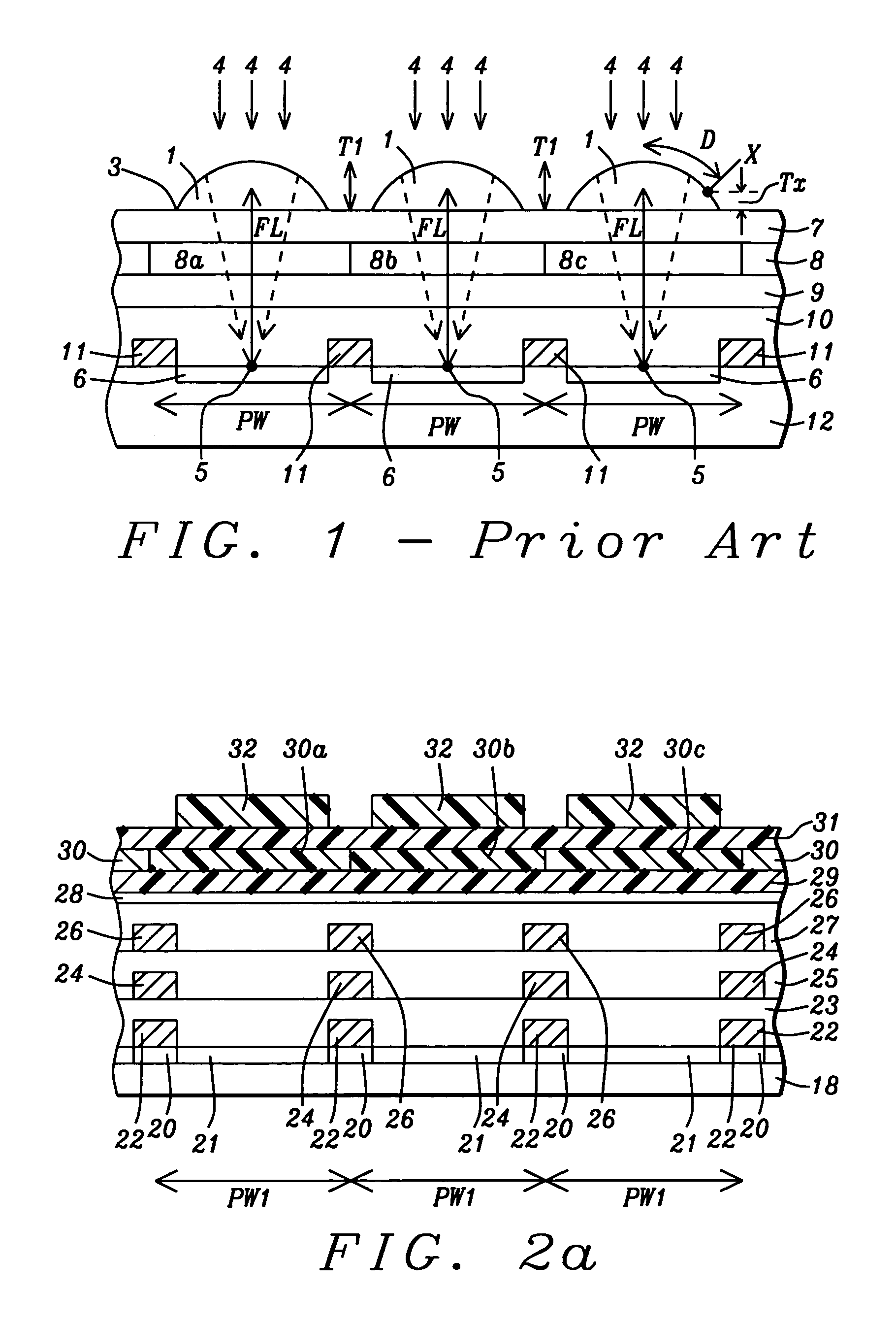

[0022] Referring to FIG. 2a, a substrate 18 is provided that may contain active and passive devices that are not shown in order to simplify the drawing. A lower stack of layers for a CMOS image sensor will now be described. A first dielectric layer 20 such as SiO2 is deposited on the substrate 18 and a photodiode array comprised of photodiodes 21 is fabricated within the first dielectric layer by conventional means. An interconnect structure comprised of a first metal (ILM) layer 22 is formed on dielectric layer 20 but not o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com