Optical waveguide and spot size converter using this

一种光波导、模转换的技术,应用在光波导的耦合、光导、光学等方向,能够解决难以将模直径调整光纤等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

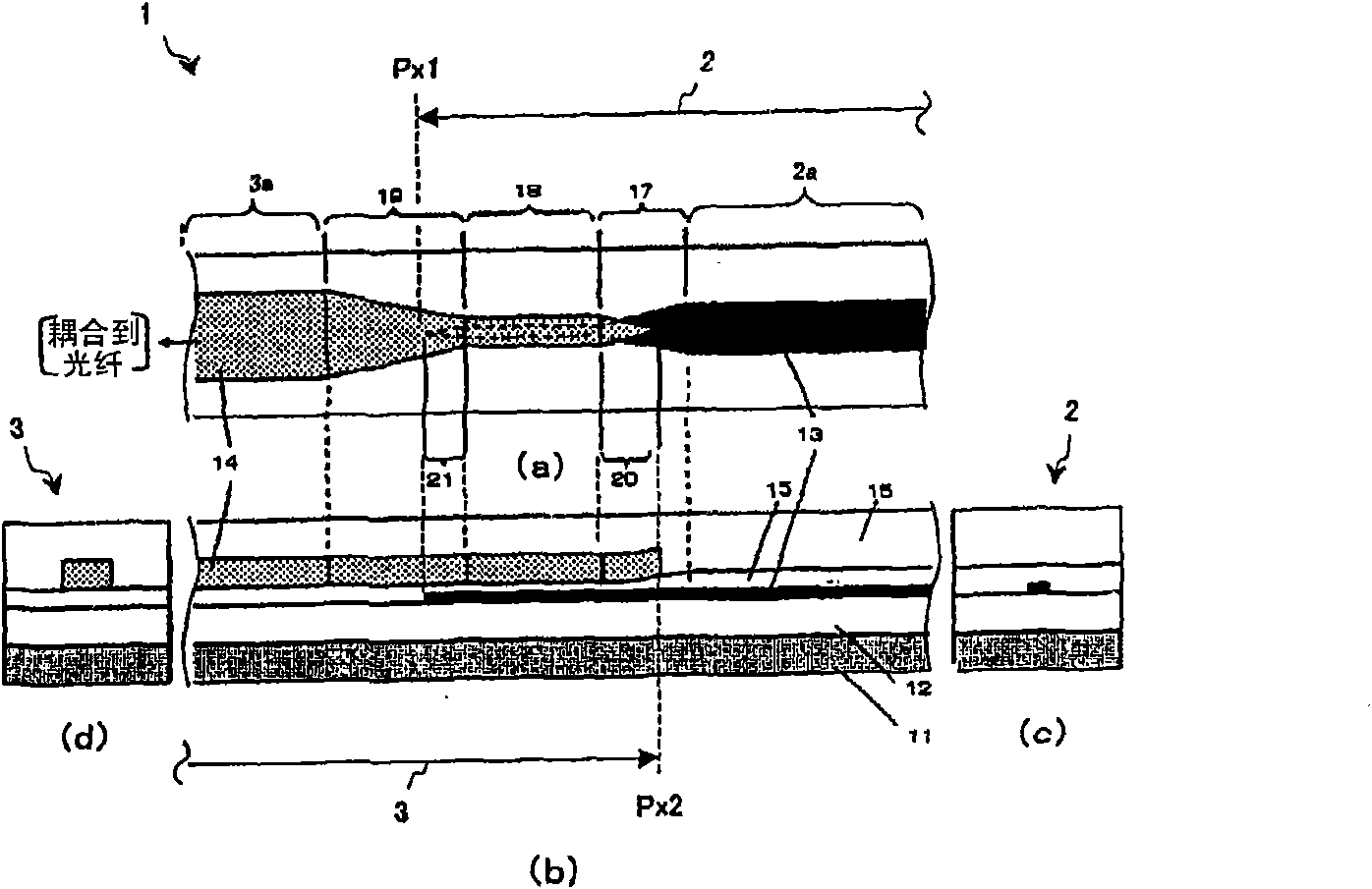

[0057] figure 1 is a schematic diagram schematically showing an example of the configuration of the spot size converter using the optical waveguide 1 according to the first example of the present invention. figure 1 A is a cross-sectional view of the main part of the upper surface. figure 1 B is a cross-sectional view of the main part of the plane. figure 1 C is a cross-sectional view of the main part of the right side. figure 1 D is a sectional view of the main part of the left side. Incidentally, figure 1 A and figure 1 B shows the cross-sectional surface of the main part of the optical waveguide 1 . As shown by the wavy lines in the figure, both ends of the optical waveguide 1 are not limited to the end faces of the actual waveguide chip. Furthermore, in the case of the example shown by this figure, the optical waveguide 1 is coupled with an optical fiber. Alternatively, the optical waveguide 1 can be applied to other cases such as when the optical waveguide 1 is cou...

example 2

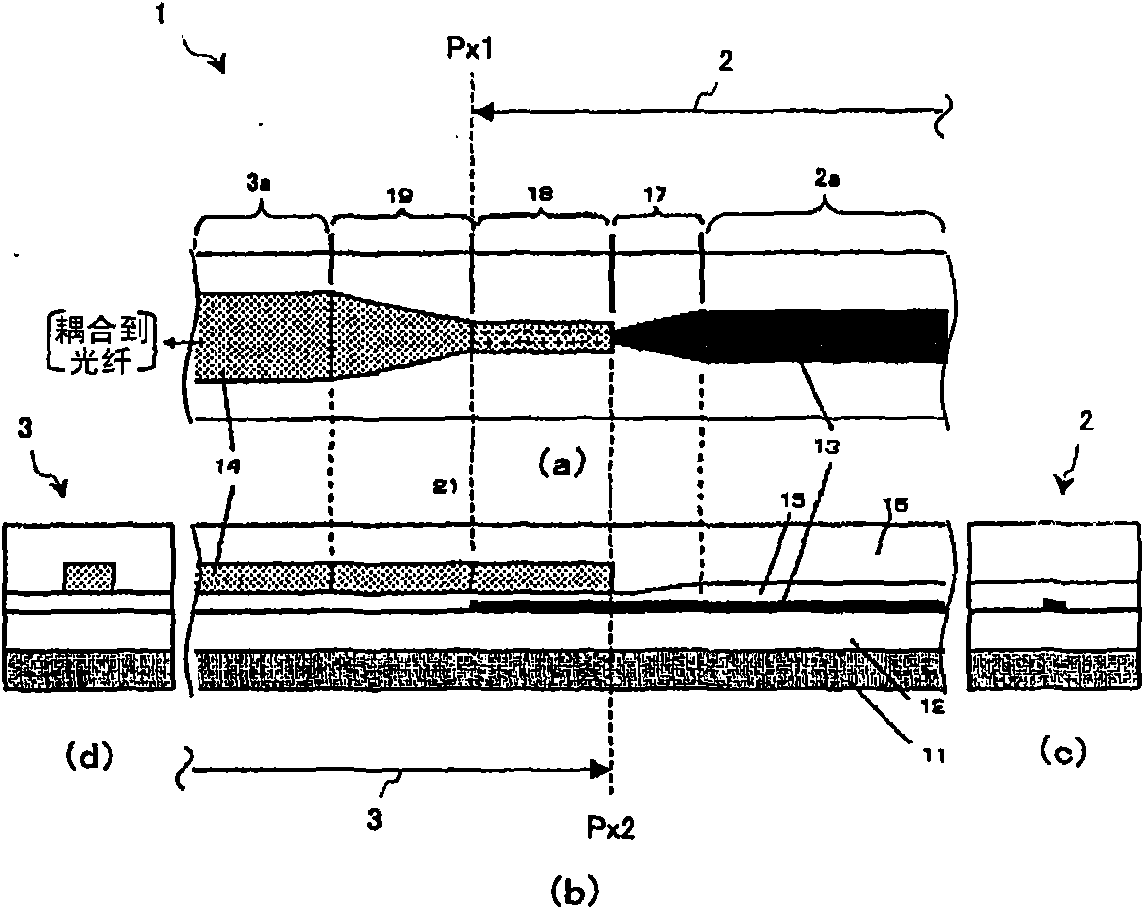

[0074] Next, a second example of the present invention will be described in detail with reference to the drawings.

[0075] figure 2 is a schematic diagram schematically showing an example of the structure of the optical waveguide 1 according to the present example. figure 2 A is a cross-sectional view of the main part of the upper surface. figure 2 B is a cross-sectional view of the main part of the plane. figure 2 C is a cross-sectional view of the main part of the right side. figure 2 D is a sectional view of the main part of the left side.

[0076] figure 2 A to figure 2 The optical waveguide 1 of this example shown in D has the same basic structure as that of the first example. However, the difference between this example and the first example is that the optical waveguide of this example does not have the first non-reflective terminal portion 20 and the second non-reflective terminal portion 21 . This difference is described next.

[0077] If complete coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com