Bending insensitive optical fiber and preparing method thereof

An optical fiber preform, optical fiber technology, applied in glass manufacturing equipment, glass fiber products, optics, etc., can solve problems such as increasing equipment, increasing costs, and reducing fiber water peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

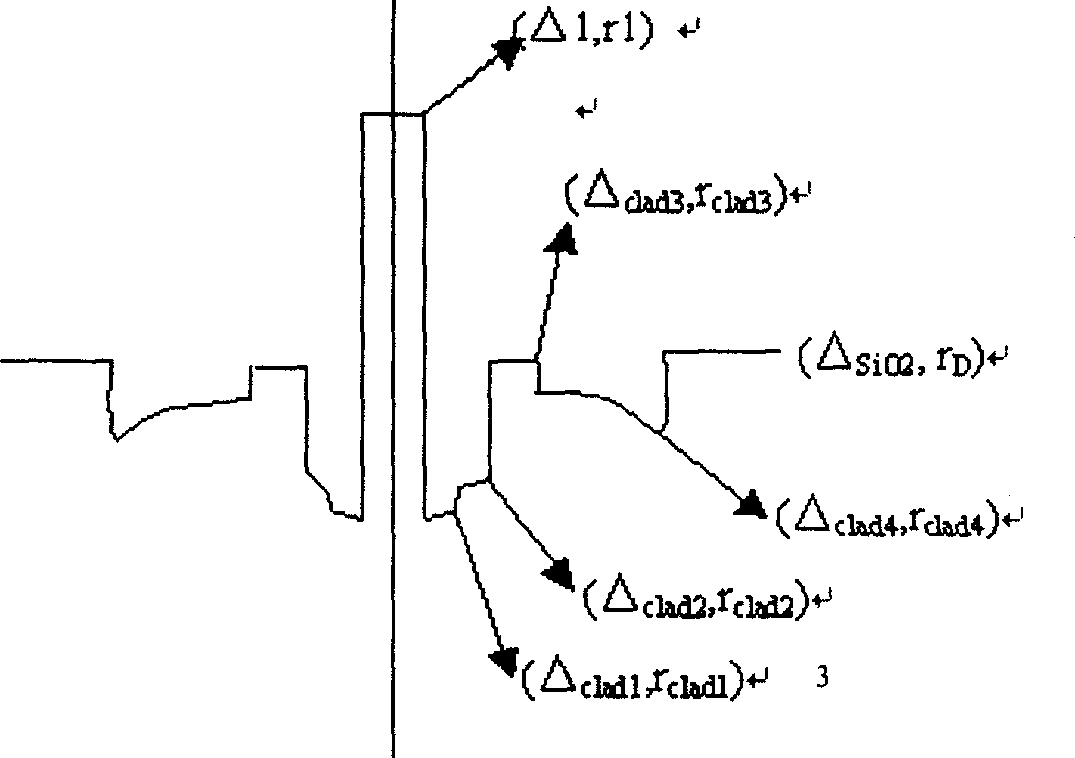

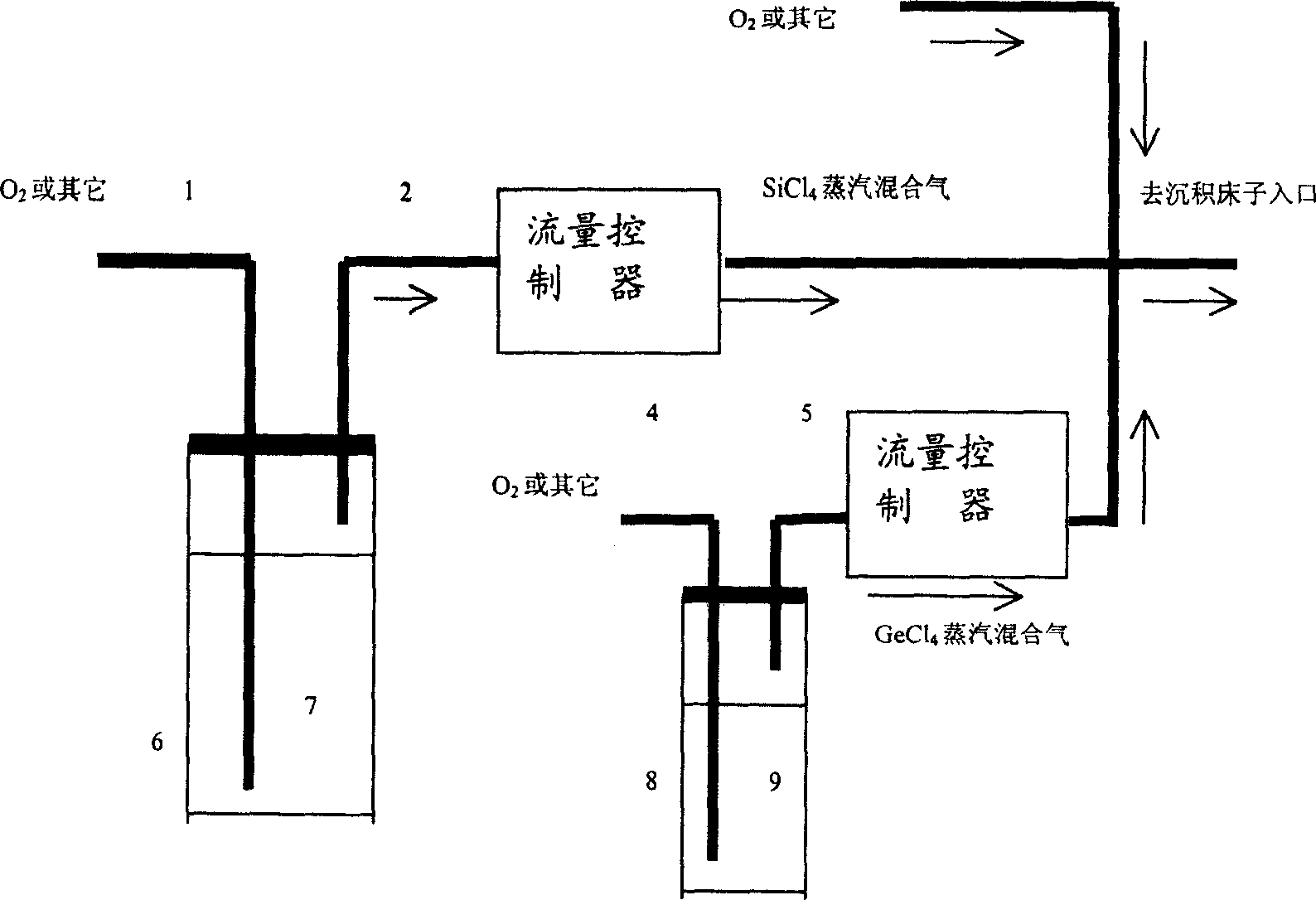

[0044] According to the ratio of raw materials and process parameters shown in Table 1, under the control of computer program, adopt PCVD process to manufacture the optical fiber of the present invention, its waveguide structure of the prepared optical fiber is as follows figure 1 shown. Install the prepared reaction substrate tube on the deposition equipment, raise the temperature of the preheating furnace to 1150°C, and compile the computer program; turn on the microwave generator, and start to deposit according to the program customized by the formula. After polishing, transition, and Deposition of the quad cladding, third cladding, second cladding, first cladding and core layer followed by stopping the microwave and computer program. Lift the deposited optical fiber preform to the rod-forming equipment for melting and shrinking. During the rod-forming process, oxygen and Freon are introduced to corrode, and then burnt from the gas outlet. During the burn-in process, the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| dispersion value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com