Modified freeze dehydration method for preparing porous material

A technology of freeze-drying and porous materials, which is applied in the direction of drying solid materials without heating, drying solid materials, drying, etc., which can solve the problems of less porous ceramics and metal materials, and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

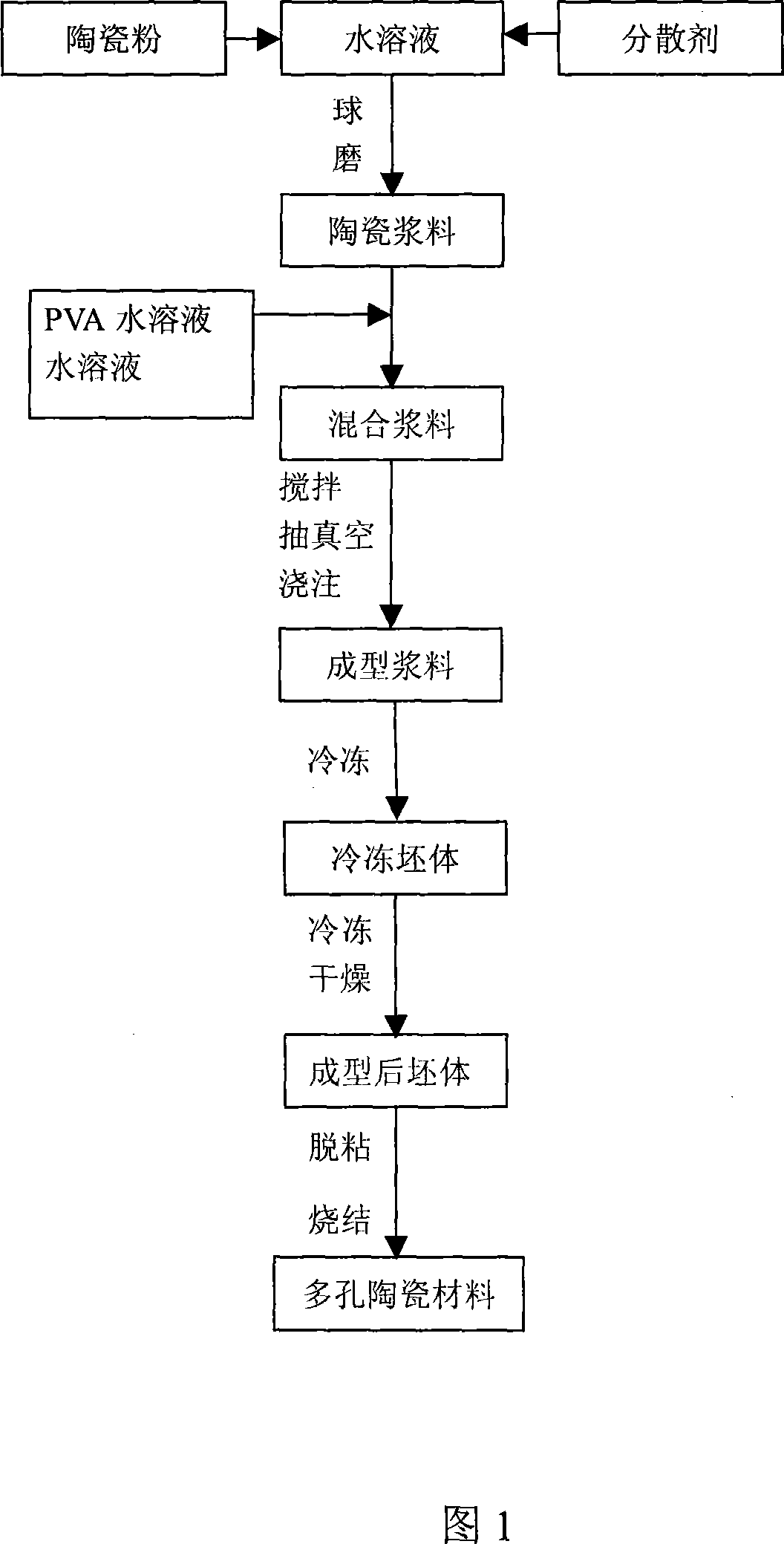

Method used

Image

Examples

example 1

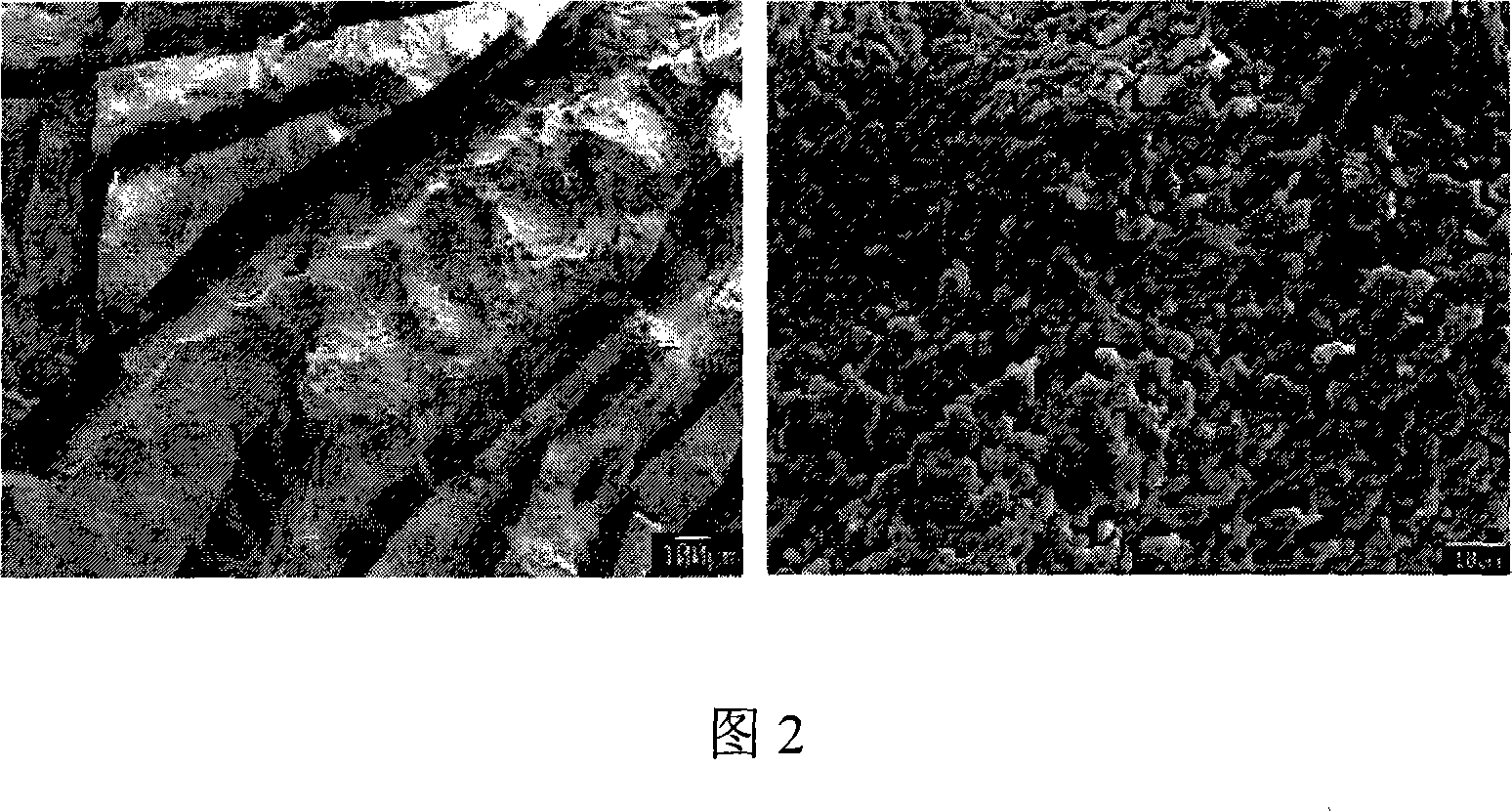

[0043] Example 1: In a 250mL polyethylene mill bottle, weigh 20g of hydroxyapatite, add 0.22g of potassium polyacrylate and 19.6g of deionized water, and add a certain proportion of alumina balls, ball mill and mix for 24 hours. Put the dispersed slurry into a vacuum drying oven for vacuum degassing. Then pour the slurry with the air bubbles removed into the mold, put it into the freezer of the refrigerator and freeze it at a low temperature of -10 to -20°C for about 48 hours. After the solid is formed, take the hydroxyapatite solid out of the mold and immediately put it into the drying oven of a freeze dryer, first keep it at 10°C and a vacuum of 9Pa for 4h, then raise the temperature of the sample to 60°C, and keep it warm for about 5h. Finally, a porous hydroxyapatite green body is obtained. The freeze-dried porous green body was sintered at 1300°C for 1 hour to obtain porous hydroxyapatite, whose bulk density and open porosity were 2.12g / cm 3 and 28.5%.

example 2

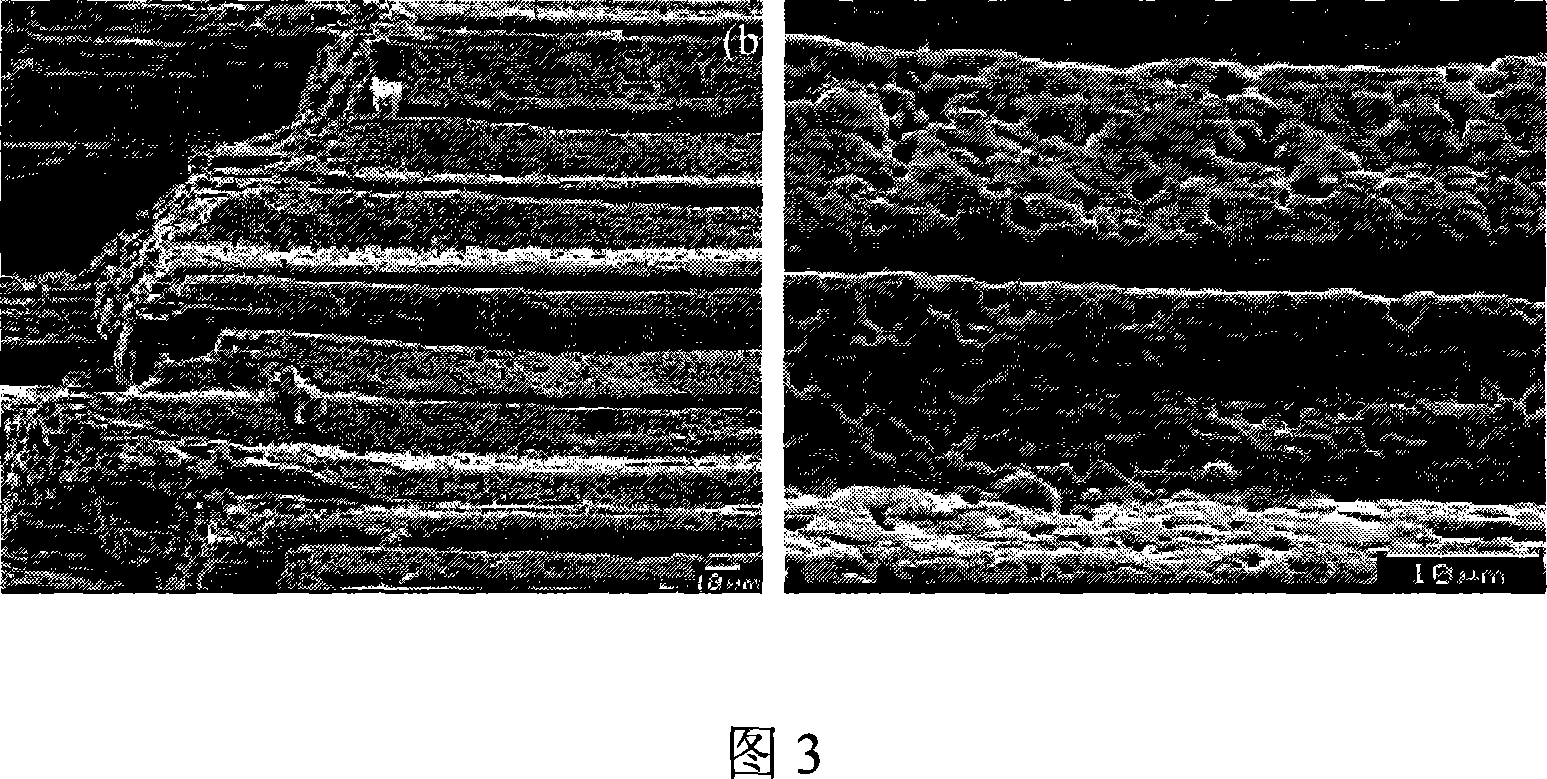

[0044] Example 2: In a 250mL polyethylene mill bottle, weigh 20g of hydroxyapatite, add 0.22g of potassium polyacrylate and 19.6g of deionized water, and add a certain proportion of alumina balls, ball mill and mix for 24 hours. Add 3.33g of PVA aqueous solution with a concentration of 12wt%, mechanically stir for 0.5h, and put the dispersed slurry into a vacuum drying oven for vacuum degassing. Then pour the slurry with the air bubbles removed into the mold, put it into the freezer of the refrigerator and freeze it at a low temperature of -10 to -20°C for about 48 hours. After the solid is formed, take the hydroxyapatite solid out of the mold and immediately put it into the drying oven of a freeze dryer, first keep it at 10°C and a vacuum of 9Pa for 4h, then raise the temperature of the sample to 60°C, and keep it warm for about 5h. Finally, a porous hydroxyapatite green body is obtained. The freeze-dried porous green body was sintered at 1300°C for 1 hour to obtain porous h...

example 3

[0045] Example 3: In a 250mL polyethylene mill bottle, weigh 20g of hydroxyapatite, add 0.22g of potassium polyacrylate and 19.6g of deionized water, and add a certain proportion of alumina balls, ball mill and mix for 24 hours. Add 10 g of PVA aqueous solution with a concentration of 12 wt %, mechanically stir for 0.5 h, and put the dispersed slurry into a vacuum drying oven for vacuum degassing. Then pour the slurry with the air bubbles removed into the mold, put it into the freezer of the refrigerator and freeze it at a low temperature of -10 to -20°C for about 48 hours. After the solid is formed, take the hydroxyapatite solid out of the mold and immediately put it into the drying oven of a freeze dryer, first keep it at 10°C and a vacuum of 9Pa for 4h, then raise the temperature of the sample to 60°C, and keep it warm for about 5h. Finally, a porous hydroxyapatite green body is obtained. The freeze-dried porous green body was sintered at 1300°C for 1 hour to obtain porous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Open porosity | aaaaa | aaaaa |

| Open porosity | aaaaa | aaaaa |

| Open porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com