Dry cooling device and cooling method for friction stir welding seam

A dry cooling and friction stir technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of polluted welding site, complicated operation, and complicated operation of liquid nitrogen cooling method, so as to avoid pollution and improve cooling. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should understand that following specific embodiment is only for illustrating the present invention and is not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand the present invention Modifications in various equivalent forms fall within the scope defined by the appended claims of the present application.

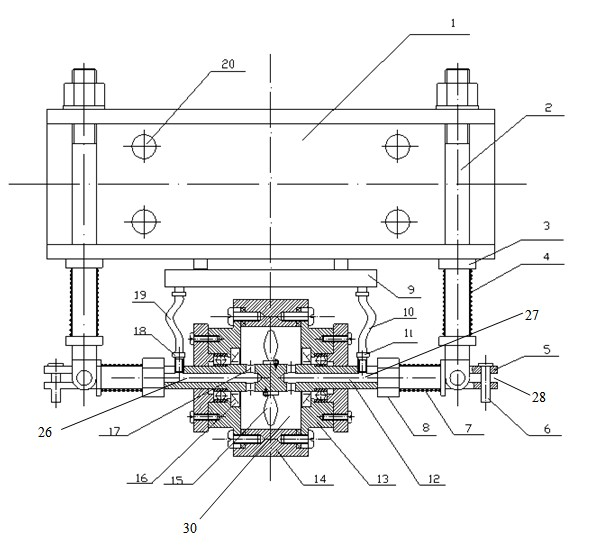

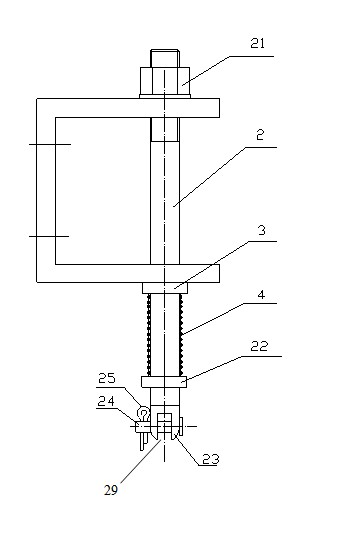

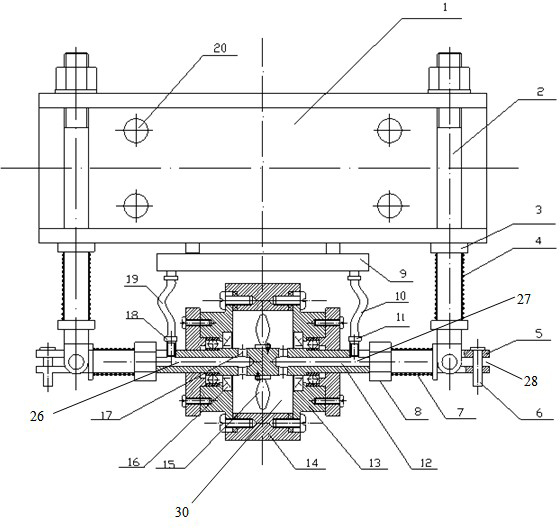

[0016] Please combine figure 1 and figure 2 As shown, the present invention discloses a friction stir weld dry cooling device, which includes a bracket 1, a pair of support rods 2 installed on both sides of the bracket 1 and extending out of the bracket 1, and a hollow roller shaft connecting the two support rods 2 at the same time 12. A pair of roller end caps 13 installed on the hollow roller shaft 12, cylindrical rollers 14 connected to the roller end caps 13, blades...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com