Method for preparing porous magnetic nanoclusters through etching

A magnetic nano and crystal cluster technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of inability to prepare magnetic clusters, inability to carry out hierarchical modification, single, etc., and achieve cheap raw materials, The effect of easy surface and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

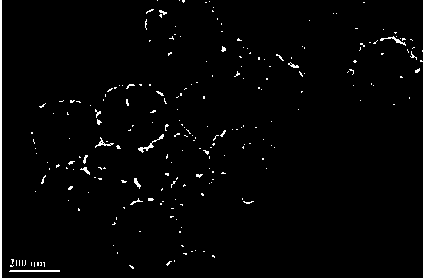

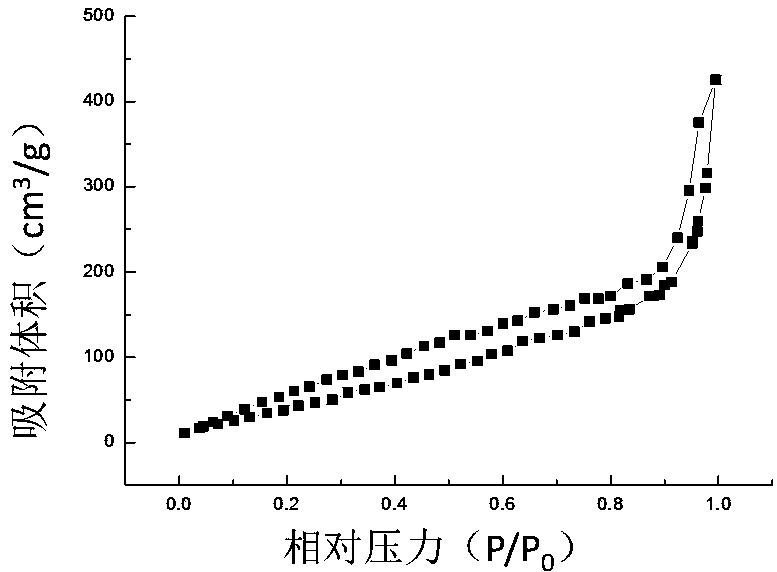

[0025] Embodiment 1: specific surface area is 240m 2 / g porous magnetic nanoclusters were prepared.

[0026] Disperse 0.5 g of the prepared magnetic clusters in 500 mL of DMF, add 1 mL of methyl thioglycolate, 10 mL of hydrazine hydrate, and 0.3 g of azobisisobutyronitrile, under the protection of nitrogen atmosphere, at 80 °C Under mechanical stirring for 0.5 h. The product magnetic clusters were separated by magnetic separation, washed with absolute ethanol to remove unreacted reactants, and dried. Porous magnetic nanocrystal clusters are obtained by etching. The specific surface area of the porous magnetic nanocrystal cluster is 240m 2 / g.

Embodiment 2

[0027] Embodiment 2: specific surface area is 463m 2 / g porous magnetic nanoclusters were prepared.

[0028] Disperse 0.5 g of the prepared magnetic clusters in 500 mL of DMF, add 1 mL of methyl thioglycolate, 10 mL of hydrazine hydrate, and 0.3 g of azobisisobutyronitrile, under the protection of nitrogen atmosphere, at 80 °C Under mechanical stirring for 0.75 h. The product magnetic clusters were separated by magnetic separation, washed with absolute ethanol to remove unreacted reactants, and dried. Porous magnetic nanocrystal clusters are obtained by etching. The specific surface area of the porous magnetic nanocrystal cluster is 463m 2 / g.

Embodiment 3

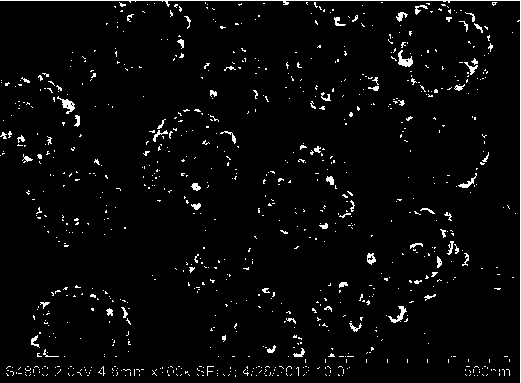

[0029] Embodiment 3: specific surface area is 684m 2 / g porous magnetic nanoclusters were prepared.

[0030] Disperse 0.5 g of the prepared magnetic clusters in 500 mL of DMF, add 1 mL of methyl thioglycolate, 10 mL of hydrazine hydrate, and 0.3 g of azobisisobutyronitrile, under the protection of nitrogen atmosphere, at 80 °C Under mechanical stirring for 1.0 h. The product magnetic clusters were separated by magnetic separation, washed with absolute ethanol to remove unreacted reactants, and dried. Porous magnetic nanocrystal clusters are obtained by etching. The specific surface area of the porous magnetic nanocrystal cluster is 684m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com