Method for using forming rollers high-efficiency process bearing channel cutting tool

A technology of bearing groove and form grinding, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, can solve problems such as difficult processing, low work efficiency, and poor surface quality, and achieve reduced processing difficulty, good surface quality, and high processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

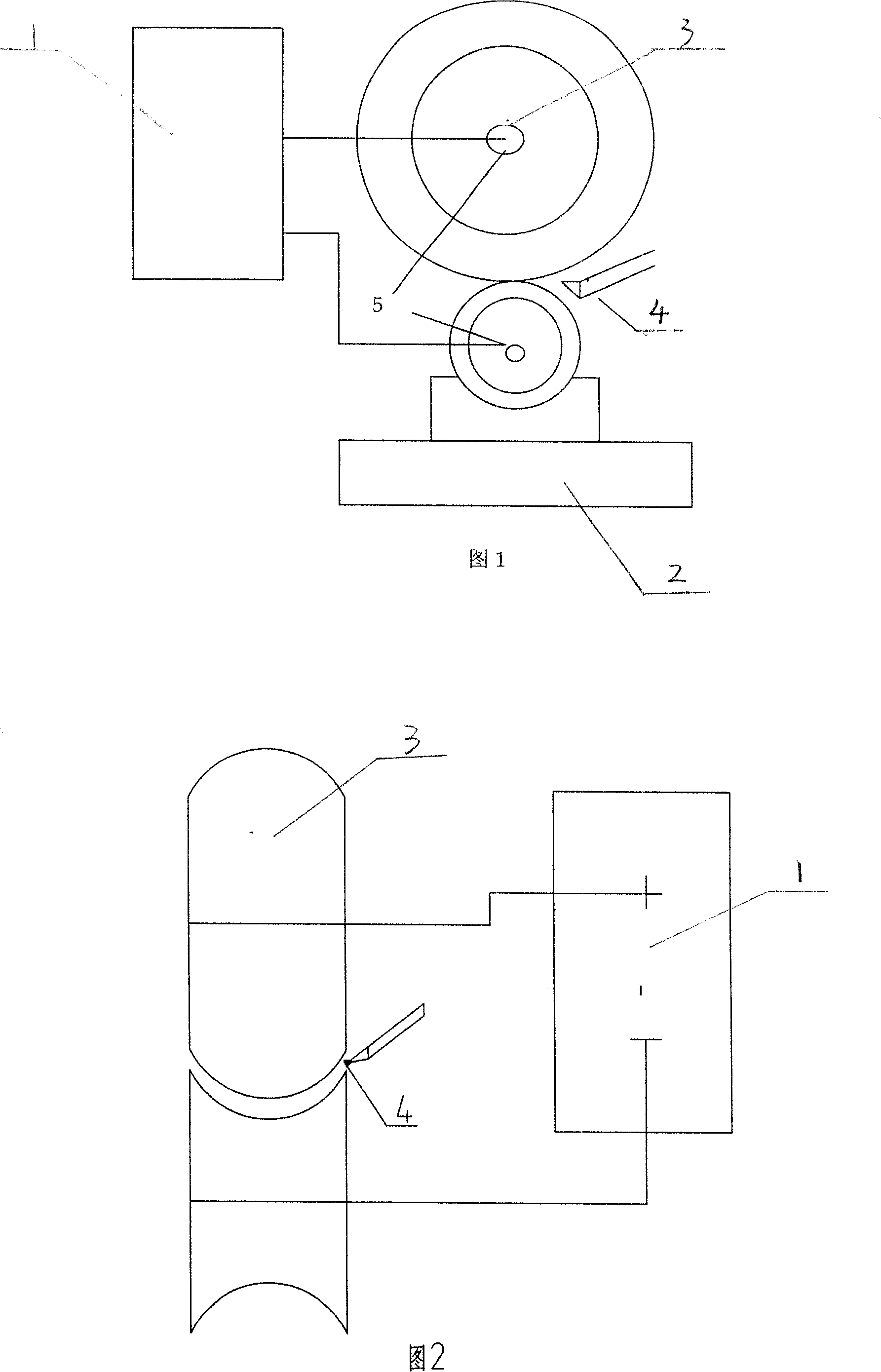

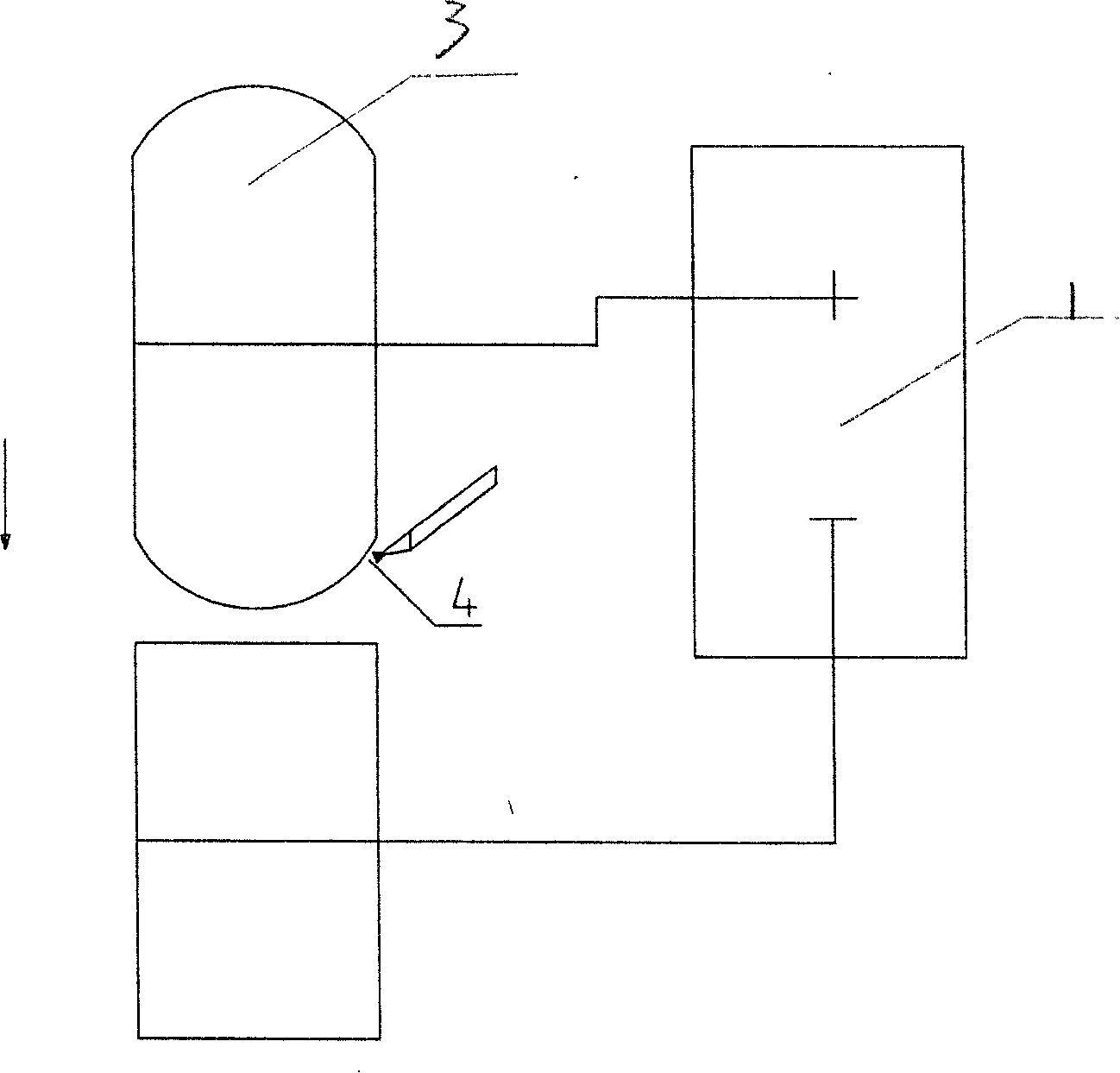

[0019] Below in conjunction with accompanying drawing, concrete technical scheme of the present invention and work process are further described:

[0020] The scheme that the present invention provides is:

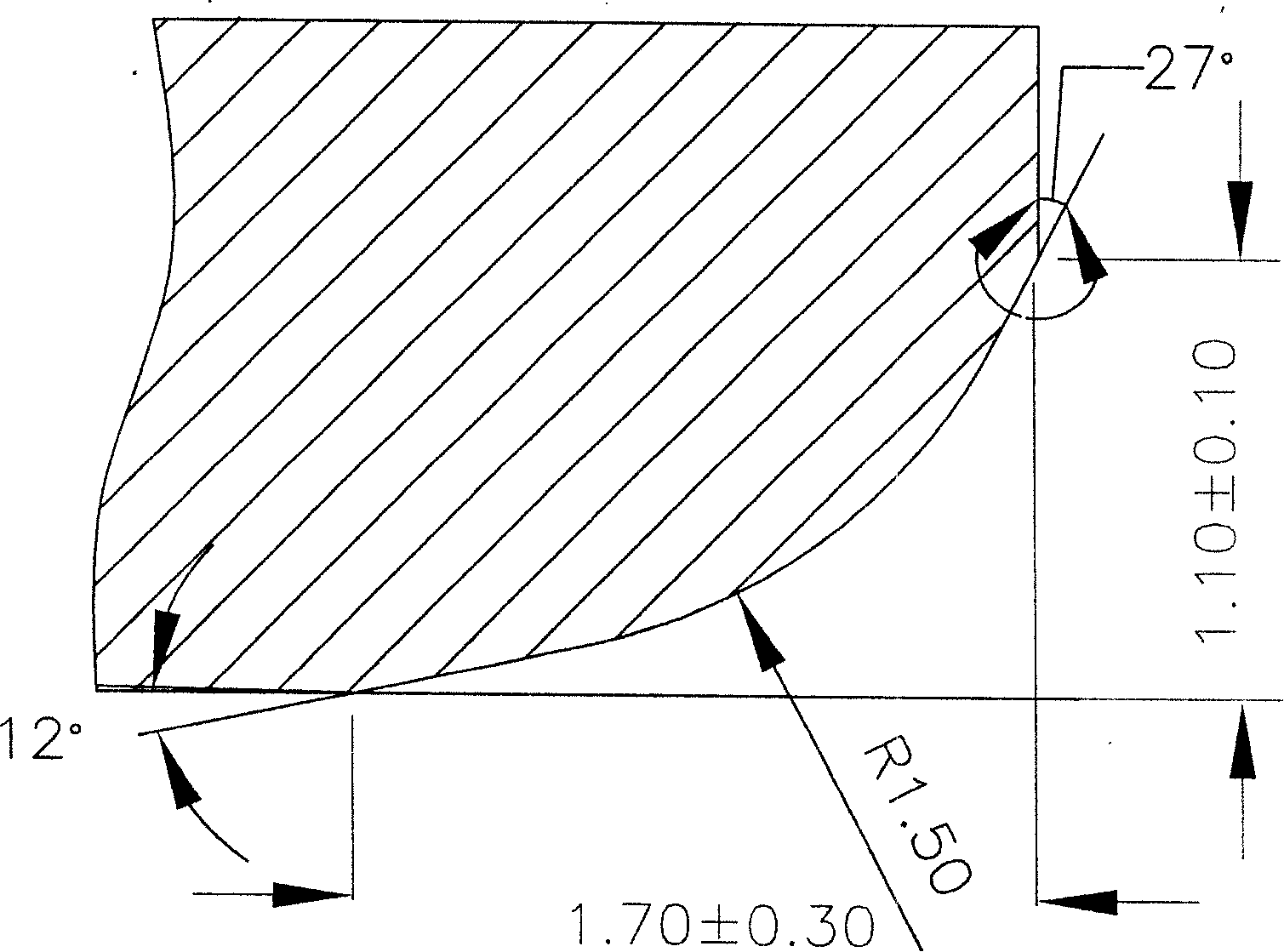

[0021] 1. First design the structure and size of the tool according to the requirements of the bearing channel, and design the structure and size of the electrode for dressing the grinding wheel under the premise of comprehensively considering the feeding direction of the grinding wheel and the machining allowance.

[0022] 2. After the electrode is designed and manufactured, the electrode is used as the cathode and the grinding wheel is used as the anode, respectively installed on the ELID shaping system, and the profile corresponding to the electrode is shaped on the grinding wheel by using the ELID electric spark;

[0023] 3. Use the profile of the shaped grinding wheel as the anode of ELID dressing, and use cemented carbide as the cathode to grind the corresponding too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com