Aluminum alloy hub for super lightweight truck or passenger car and manufacturing method thereof

A technology for aluminum alloy wheels and manufacturing methods, which is applied to wheels, web-type wheels, vehicle parts, etc., can solve the problems of potential safety hazards, low manufacturing precision, and long manufacturing cycle, and achieve the effects of reducing emissions, saving weight, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

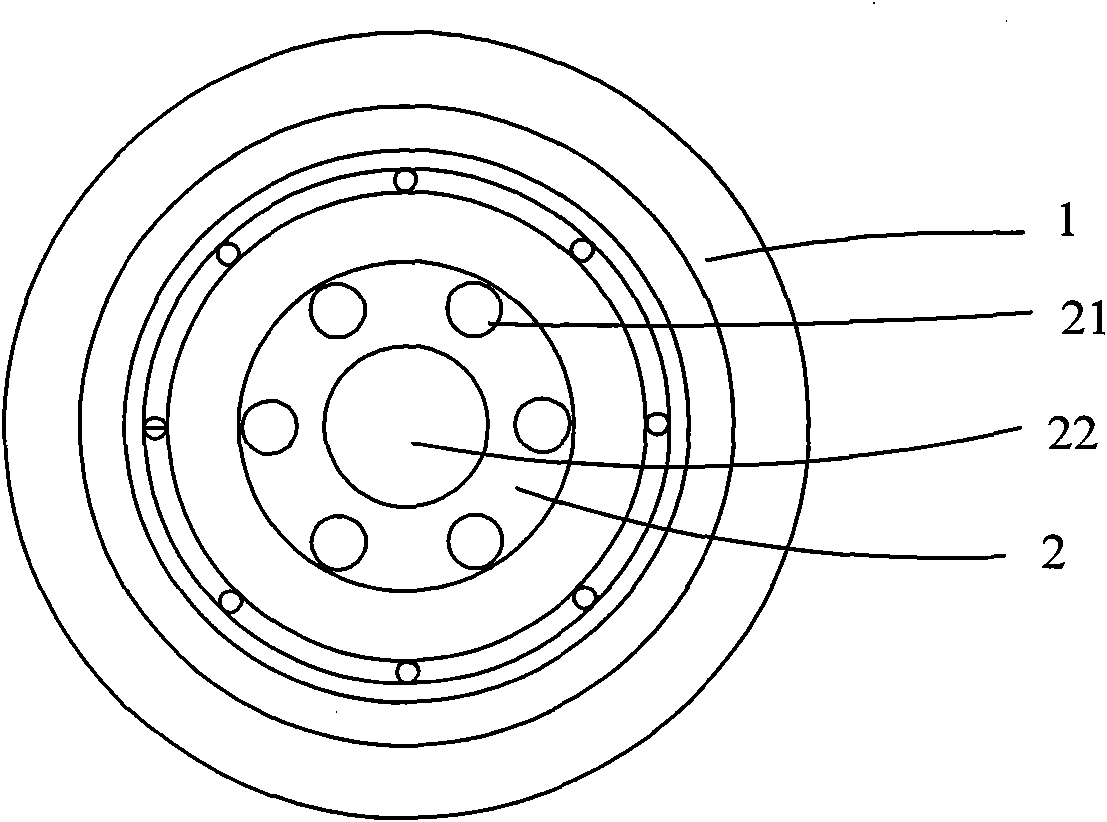

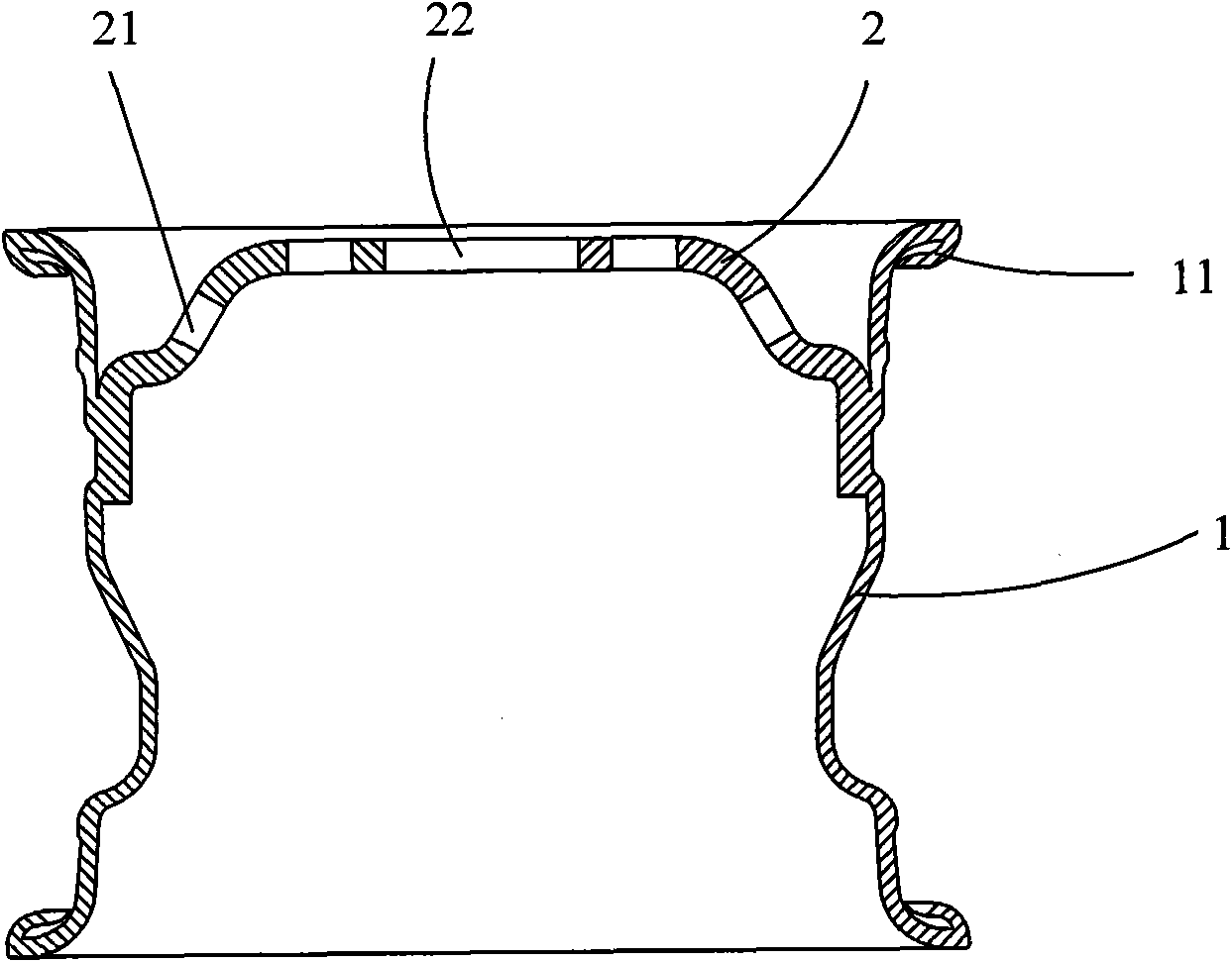

[0033] See figure 1 with figure 2 . The aluminum alloy wheel hub of the present invention includes a rim 1 and spokes 2 arranged on the rim 1. The rim 1 is a central hollow structure formed by integral spinning and forming of aluminum alloy plates, and the edges thereof are turned into a bent portion 11. The spoke 2 is integrally connected to the hollow part of the rim and separates the hollow part of the rim. It is a bowl-shaped structure formed by integral spinning and forming of an aluminum alloy plate, and is provided with ventilation holes 21 and positioning holes 22. The positioning holes are located The center of the spoke is used for positioning, and the ventilation hole surrounds the positioning hole for ventilation. The rim 1 and the spokes 1 are connected by spinning to form an inverted stepped connection, and are connected as a whole by friction stir welding.

[0034] In this specific embodiment, the rim 1 is integrally spun from a high-strength cold-rolled aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com