Vacuum circuit-breaking switch contact material preparation method

A contact material, vacuum circuit breaker technology, applied in the direction of metal/alloy conductors, etc., can solve the problems of reducing the reliability of vacuum circuit breakers, the influence of contact material structure, and difficulty in achieving densification, etc., achieving fine particles, low production costs, The effect of increased cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

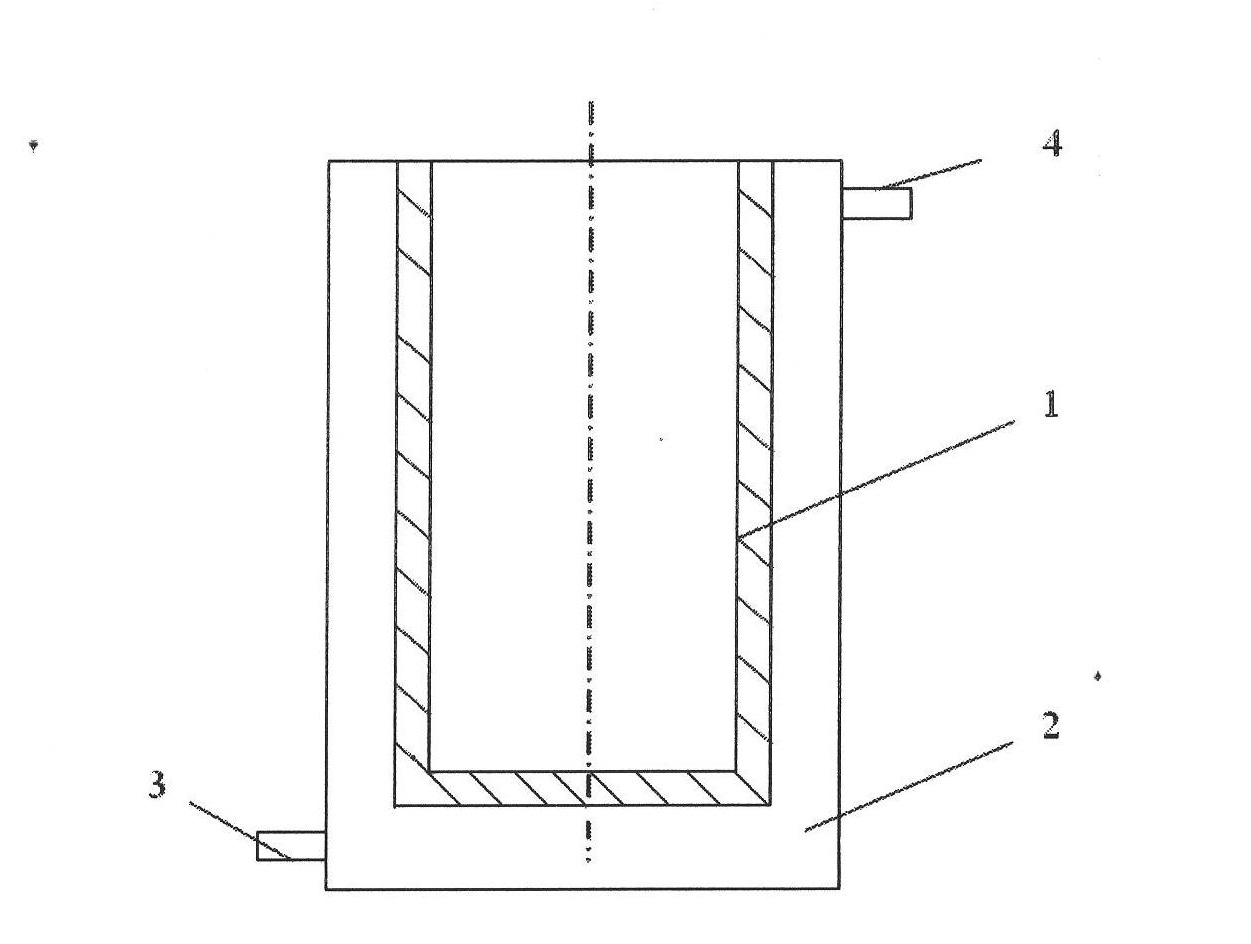

Method used

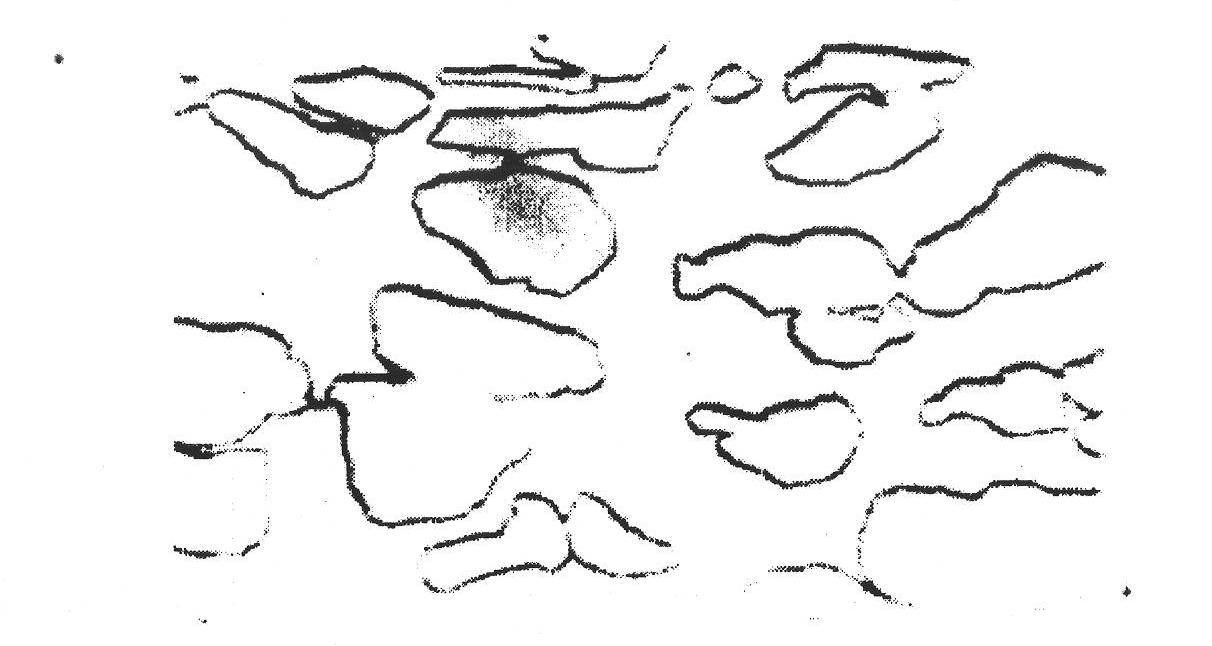

Image

Examples

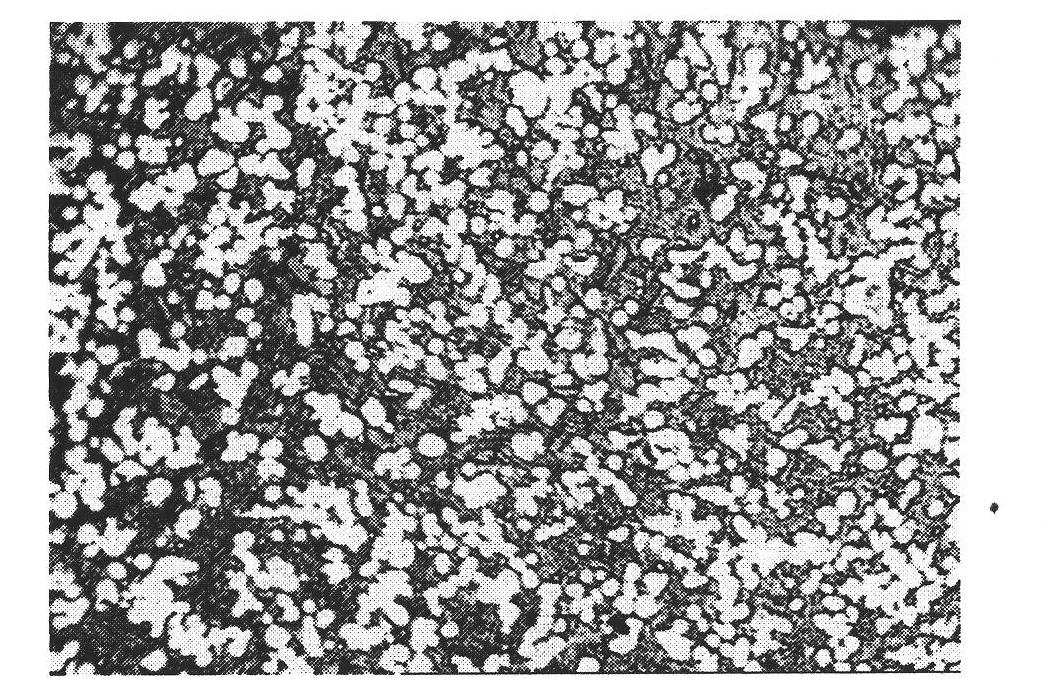

Embodiment 1

[0023] According to 25% chromium ingredients, in the vacuum induction furnace, control the vacuum degree in the induction furnace to be less than 1×10 -1 Pa, heated to 1850 ℃ for refining for 20 minutes, and the casting temperature was controlled at 1750 ℃ to prepare CuCr25 contact material. The physical and mechanical properties of the material are shown in Table 1.

[0024] Table 1 Physical and mechanical properties of CuCr25 alloy materials

[0025]

[0026] For the convenience of comparison, Table 2 also lists the properties of domestic CuCr50 and CuCr25 produced by Westinghouse.

[0027] Table 2 Physical and mechanical properties of domestic and imported copper-chromium alloy materials

[0028]

[0029] It can be seen from the comparison between Table 1 and Table 2 that the electrical conductivity of the CuCr25 material prepared by the present invention is more than 30% higher than that of the ordinary CuCr25 material, and more than doubled that of the CuCr50 mat...

Embodiment 2

[0032] According to 20% chromium ingredients, in the vacuum induction furnace, control the vacuum degree in the induction furnace to be less than 1×10 -1 Pa, heated to 1800°C for refining for 20 minutes, and the casting temperature was controlled at 1700°C to prepare a CuCr20 contact material. The physical and mechanical properties of the material are shown in Table 3.

[0033] Table 3 Physical and mechanical properties of CuCr20 alloy materials

[0034]

Embodiment 3

[0036] According to 30% chromium ingredients, in the vacuum induction furnace, control the vacuum degree in the induction furnace to be less than 1×10 -1 Pa, heated to 1900°C for refining for 20 minutes, and the casting temperature was controlled at 1750°C to prepare a CuCr30 contact material. The physical and mechanical properties of the material are shown in Table 4.

[0037] Table 4 Physical and mechanical properties of CuCr30 alloy materials

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com