Lithium battery metal oxide precursor, cathode material, and preparation method thereof

A cathode material and precursor technology, applied in the field of lithium battery metal oxide precursors, can solve the problems of lithium loss, increased energy consumption of multi-materials, large gap between primary particles of precursors, etc., to overcome energy consumption, residual alkali and sulfur content reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

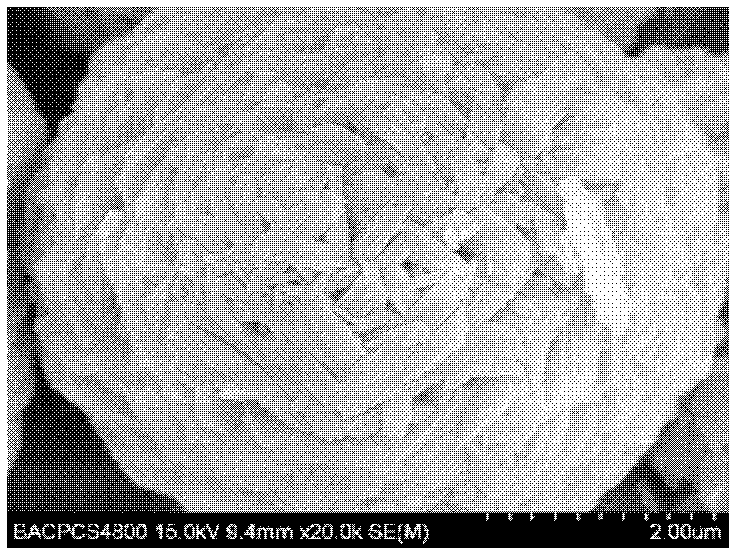

[0036] A kind of lithium battery metal oxide precursor, its molecular formula is (Ni 0.5 co 0.3 mn 0.2 ) 2 o 3 , the primary particle gap ranges from 0.25 to 1.29μm, and the sulfur content is 130ppm; the electron microscope photos are as follows figure 2 shown. Its preparation method is, the prepared Ni 0.5 co 0.3 mn 0.2 (OH) 2 Raise to 930°C at a heating rate of 5°C / min, calcinate for 6 hours under air conditions, and then lower the temperature at a rate of 5°C / min to obtain the product. Prepared Ni 0.5 co 0.3 mn 0.2 (OH) 2 Electron microscope photos such as figure 1 shown.

[0037] The multi-component material prepared by the above-mentioned metal oxide precursor, the electron microscope photo is as follows Figure 5 As shown, its molecular formula is Li 1.02 Ni 0.5 co 0.3 mn 0.2 o 2 , the alkali content of the material is 730ppm. Its preparation method is, above-mentioned precursor (Ni 0.5 co 0.3 mn 0.2 ) 2 o 3 The molar ratio with lithium is 1:1....

Embodiment 2

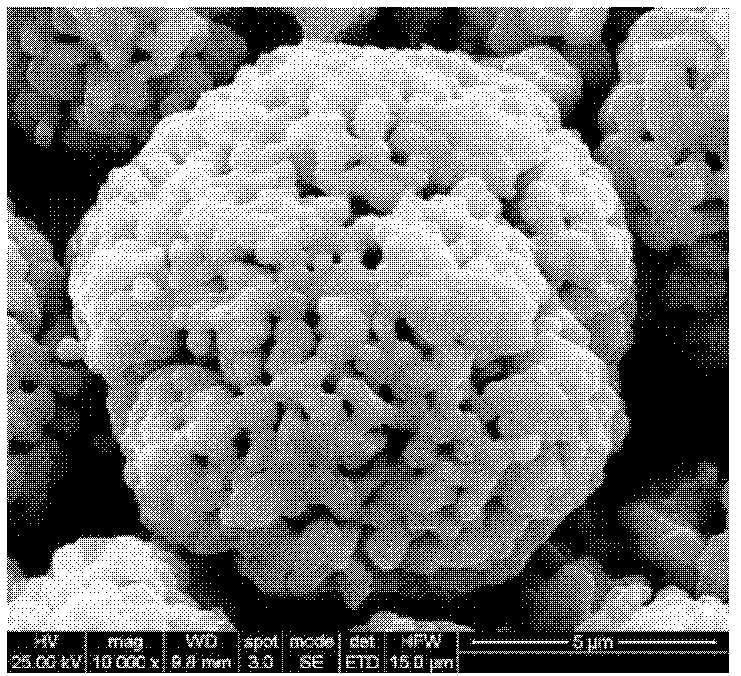

[0039] A kind of lithium battery metal oxide precursor, its molecular formula is (Ni 0.3 co 0.1 mn 0.6 ) 2 o 3 , the primary particle gap ranges from 0.13 to 0.90μm, and the sulfur content is 420ppm; the electron microscope photos are as follows image 3 shown. Its preparation method is, the prepared Ni 0.3 co 0.1 mn 0.6 (OH) 2 Raise to 800°C at a heating rate of 8°C / min, calcinate for 10 hours under air conditions, and then lower the temperature at a rate of 3°C / min to obtain the obtained product.

[0040] The multi-element material prepared by the above-mentioned metal oxide precursor, its molecular formula is Li 1.05 Ni 0.3 co 0.1 mn 0.6 o 2 , the alkali content of the material is 850ppm. Its preparation method is, above-mentioned precursor (Ni 0.3 co 0.1 mn 0.6 ) 2 o 3 The molar ratio with lithium is 1:1.05, ball milled for 8 hours, and the speed is 500r / min. 15m at ℃ 3 The flow rate of / h is passed into cold dry air, and when the temperature is lowere...

Embodiment 3

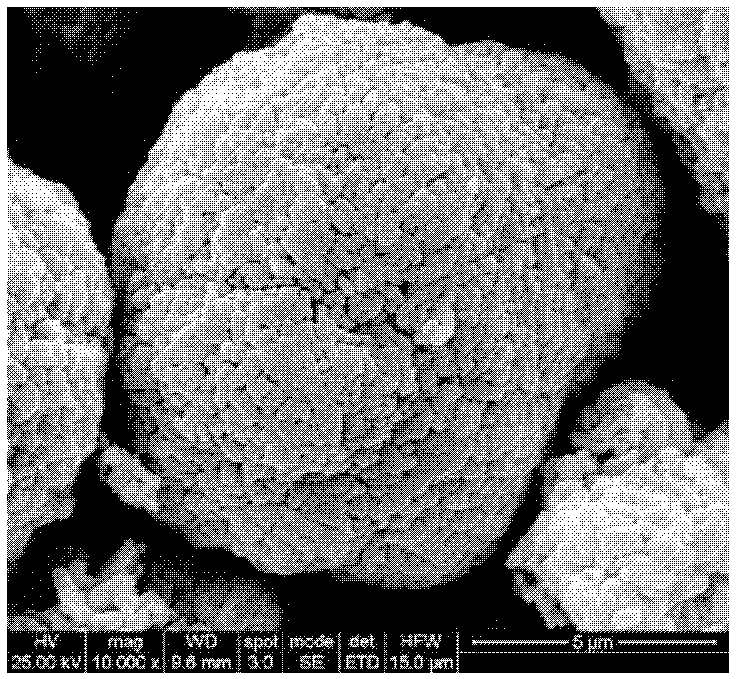

[0042] A kind of lithium battery metal oxide precursor, its molecular formula is (Ni 0.55 co 0.4 al 0.05 ) 2 o 3 , the primary particle gap ranges from 0.09 to 0.41μm, and the sulfur content is 1100ppm; the electron microscope photos are as follows Figure 4 shown. Its preparation method is, the prepared Ni 0.55 co 0.4 al 0.05 (OH) 2 Raise to 700°C at a heating rate of 5°C / min, calcinate for 3 hours under air conditions, and then lower the temperature at a rate of 1°C / min.

[0043] The multi-element material prepared from the above-mentioned metal oxide precursor, its molecular formula is LiNi 0.55 co 0.4 al 0.05 o 2 , the alkali content of the material is 1100ppm. Its preparation method is, above-mentioned precursor (Ni 0.55 co 0.4 al 0.05 ) 2 o 3 The molar ratio with lithium is 1:1, ball milled for 2 hours, the speed is 1000r / min, the mixture is loosely packed into a sagger, and the temperature is raised to 700°C for 20 hours at a heating rate of 1°C / min. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com