Silver/silver chloride electrode slice and preparation technology thereof

A silver chloride electrode and preparation process technology, applied in the direction of material electrochemical variables, material analysis by electromagnetic means, measuring devices, etc., can solve the problems of unstable electrical properties, low purity, cumbersome process, etc., and achieve compactness Micro interface, reduce production cost, improve the effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below in conjunction with the examples, but the present invention is not limited only to the following examples.

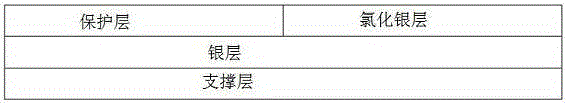

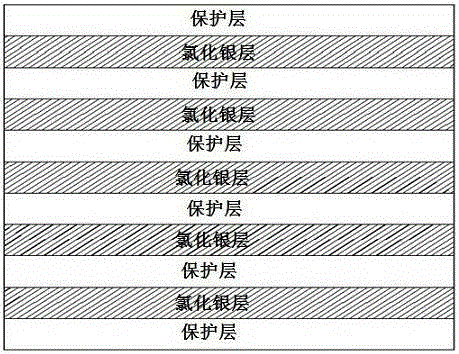

[0017] Such as figure 1 As shown, the silver / silver chloride electrode includes: a support layer, a silver layer, a protective layer, and a silver chloride layer.

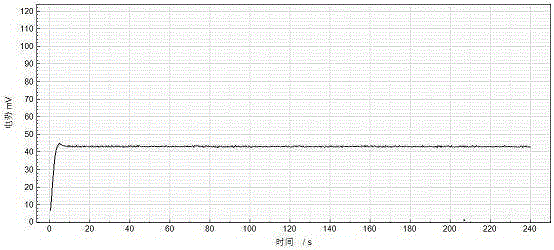

[0018] The specific implementation steps are as follows: After ultrasonic cleaning and plasma surface treatment of PET, a 3 μm silver layer is plated on the PET sheet by vacuum evaporation plating, and then a mask plate is used to protect the part that needs to be chlorinated into silver chloride, and magnetron sputtering is used to The nickel-plated layer is 0.3 μm, and the silver layer after nickel plating is placed in potassium dichromate, hydrochloric acid, and potassium chloride solution, and the silver chloride layer is prepared by oxidation treatment. Finally, the prepared silver / silver chloride electrode is used for pure Wash it with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com