Flexible electrode with carbon fiber wrapped metal oxide for capacitor and preparation method

A flexible electrode and oxide technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, can solve the problems of poor cycle stability of electrode materials, cumbersome processes, and poor controllability, and achieves low cost and controllable material structure. , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a. Weigh 10 g of polyacrylonitrile (PAN) particles into 190 mL of dimethylformamide (DMF) solvent, stir at 80°C for 60 min until completely dissolved, forming a uniform, stable, and viscous sol;

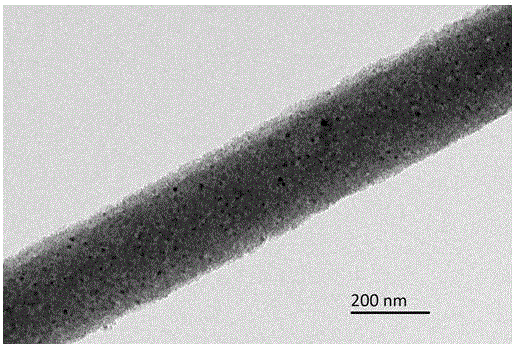

[0030] b. Dissolve 0.5g tetrabutylammonium bromide (TBAB) in 1g water, add 0.5g MnO 2 Particles were ultrasonically dispersed for 30 min, then 2.5 g of acrylonitrile (AN) and 2.5 g of azobisisobutyronitrile (AIBN) were added to the above solution, and the reaction was refluxed at 80 ° C for 3 h to obtain PAN-modified MnO 2 particle;

[0031] c. Add PAN-modified MnO to the sol solution at a mass percentage of 0.1% 2 Particles, magnetically stirred for 1h, and then ultrasonically dispersed for 0.5h to obtain uniformly dispersed MnO 2 - polyacrylonitrile (PAN) complex solution;

[0032] d. MnO 2 - Pour polyacrylonitrile (PAN) compound solution into a 10 mL glass syringe, connect the needle tip to the positive pole of the high-voltage power supply, connect the aluminum foil co...

Embodiment 2

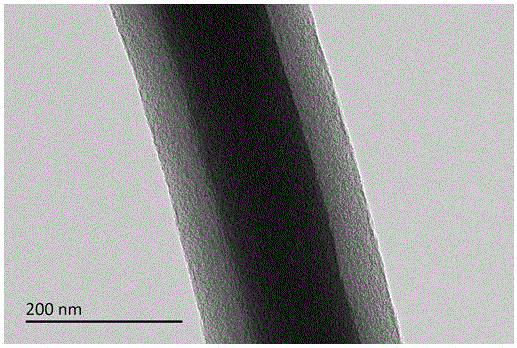

[0036] a. Weigh 10 g of polyacrylonitrile (PAN) particles into 56.6 mL of tetrahydrofuran (THF) solvent, stir at 80 °C for 90 min until completely dissolved, forming a uniform, stable, and viscous sol;

[0037] b. Weigh 10 g of polyvinylpyrrolidone (PVP-90), add it to 115 mL of absolute ethanol, and stir magnetically at room temperature for 0.5 h to obtain a PVP solution with a concentration of 8%;

[0038] c. Dissolve 0.5 g tetrabutylammonium bromide (TBAB) in 3 g water, add 5 g MnO 2 Particles were ultrasonically dispersed for 60 min, then 2.5 g of acrylonitrile (AN) and 2.5 g of azobisisobutyronitrile (AIBN) were added to the above solution, and refluxed at 80 ° C for 3 h to obtain PAN-modified MnO 2 particle;

[0039] d. Add PAN-modified MnO to the PVP solution at a mass percentage of 3% 2 Particles, magnetically stirred for 1h, and then ultrasonically dispersed for 0.5h to obtain uniformly dispersed MnO 2 - polyvinylpyrrolidone composite solution;

[0040] e. Combine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com