Method for preparing nutshell activated carbon by pyrolyzing activation technology and activated carbon

A technology of fruit shell activated carbon and activated carbon, which is applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of low product yield and high energy consumption, achieve good adsorption performance, developed pore structure, and good heat storage effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

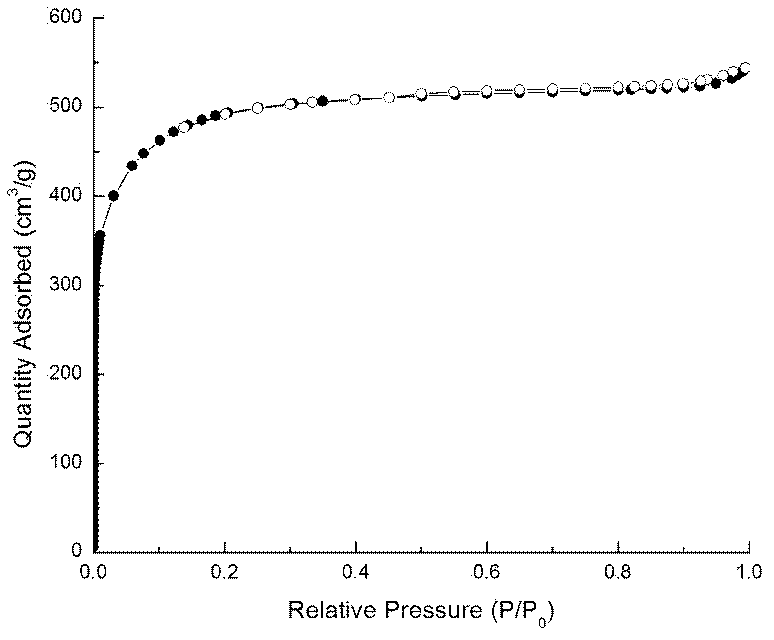

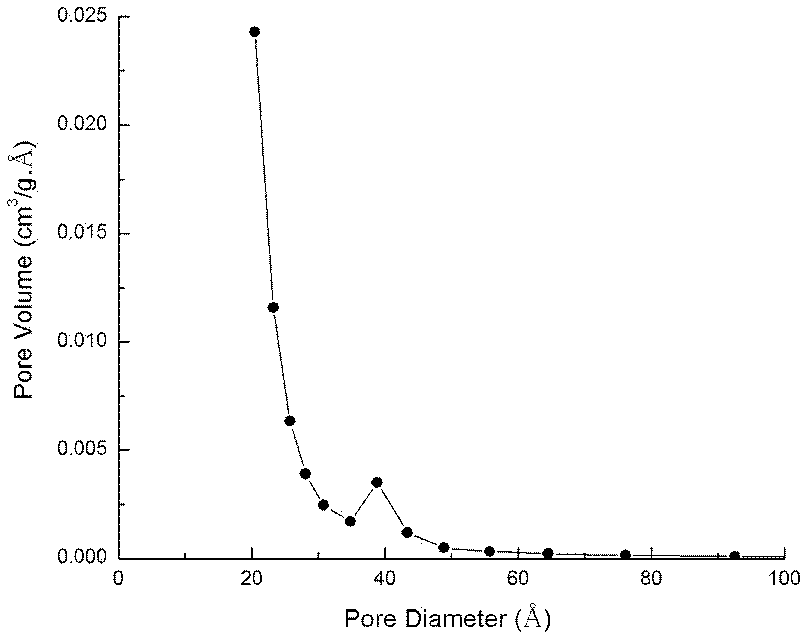

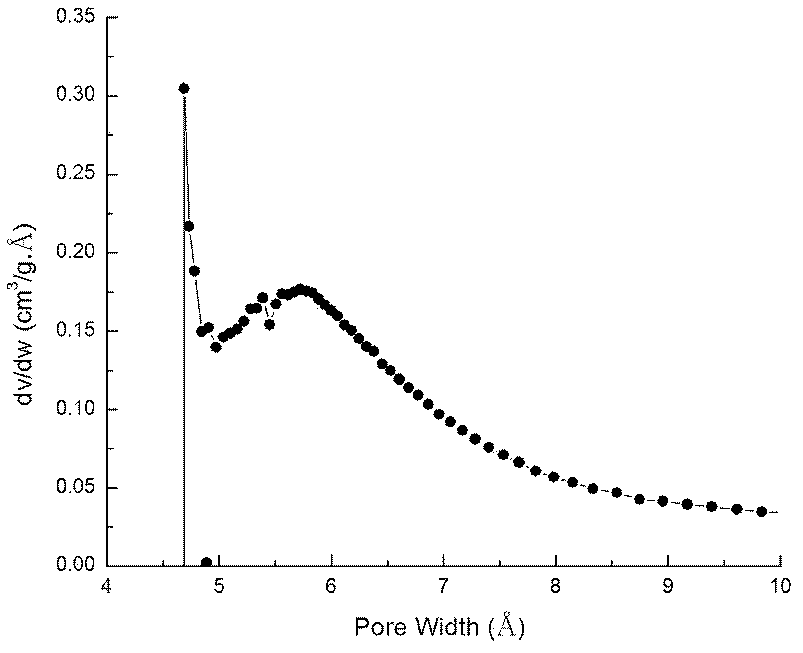

Embodiment 1

[0032] (1) Raw material crushing: crush the air-dried coconut shell raw material, sieve, take 0.85-2.00mm particles, and dry at 120°C.

[0033] (2) Airtight pretreatment before reaction: put 10g (13.15ml) coconut shell raw material in a 100ml ceramic pyrolysis reactor, and use clay or other airtight materials to seal the gap.

[0034] (3) Pyrolysis: Put the closed pyrolysis reactor containing coconut shell raw materials in a high-temperature furnace, raise the temperature to the pyrolysis temperature of 700°C at a heating rate of 10°C / min, and keep it for a certain period of time for 4 hours. At the end, the sample is taken out, washed with acid and water until neutral, and dried to become an activated carbon sample. The yield of activated carbon is 24.4%, and the specific surface area is 558m 2 / g, the iodine adsorption value is 767mg / g, and the methylene blue adsorption value is <15ml / g.

Embodiment 2

[0036](1) Raw material crushing: crush the air-dried coconut shell raw material, sieve, take 0.85-2.00mm particles, and dry at 120°C.

[0037] (2) Airtight pretreatment before reaction: put 10g (13.15ml) coconut shell raw material in a 100ml ceramic pyrolysis reactor, and use clay or other airtight materials to seal the gap.

[0038] (3) Pyrolysis: Put the closed pyrolysis reactor with coconut shell raw materials in a high-temperature furnace, raise the temperature to the pyrolysis temperature of 800°C at a heating rate of 10°C / min, and keep it for a certain period of time for 4 hours. At the end, the sample is taken out, washed with acid and water until neutral, and dried to become an activated carbon sample. The yield of activated carbon is 22.3%, and the specific surface area is 704m 2 / g, the iodine adsorption value is 892mg / g, and the methylene blue adsorption value is 30ml / g.

Embodiment 3

[0040] (1) Raw material crushing: crush the air-dried coconut shell raw material, sieve, take 0.85-2.00mm particles, and dry at 120°C.

[0041] (2) Airtight pretreatment before reaction: put 10g (13.15ml) coconut shell raw material in a 100ml pyrolysis reactor and airtight.

[0042] (3) Pyrolysis: Put the airtight pyrolysis reactor containing coconut shell raw materials in a high-temperature furnace, raise the temperature to the pyrolysis temperature of 900°C at a heating rate of 10°C / min, and keep it warm for a certain period of time for 4 hours. At the end, the sample is taken out, washed with acid and water until neutral, and dried to become an activated carbon sample. The yield of activated carbon is 18.3%, and the specific surface area is 994m 2 / g, the iodine adsorption value is 1295 mg / g, and the methylene blue adsorption value is 135 ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com