Graphene modified energy pile

A graphene modification and energy pile technology, applied in sheet pile walls, geothermal energy, geothermal power generation and other directions, can solve the problems of insufficient contact area between heat transfer tubes and fillers, poor heat transfer capacity of pile bodies, etc. Achieve the effect of improving heat transfer performance and heat storage capacity, improving heat transfer capacity, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

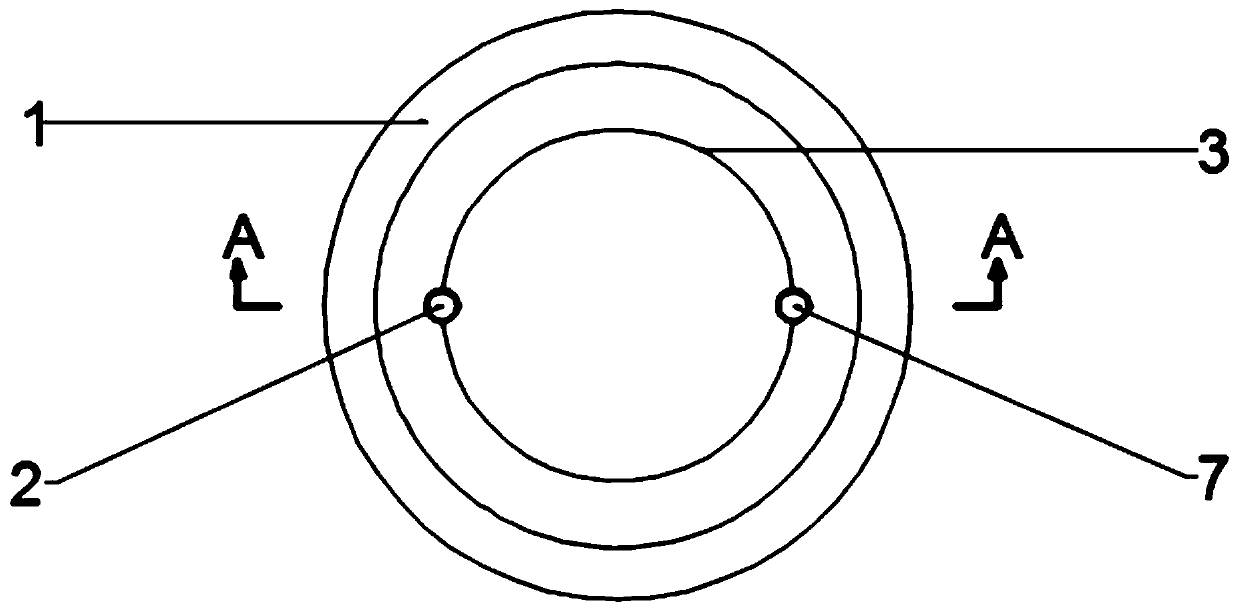

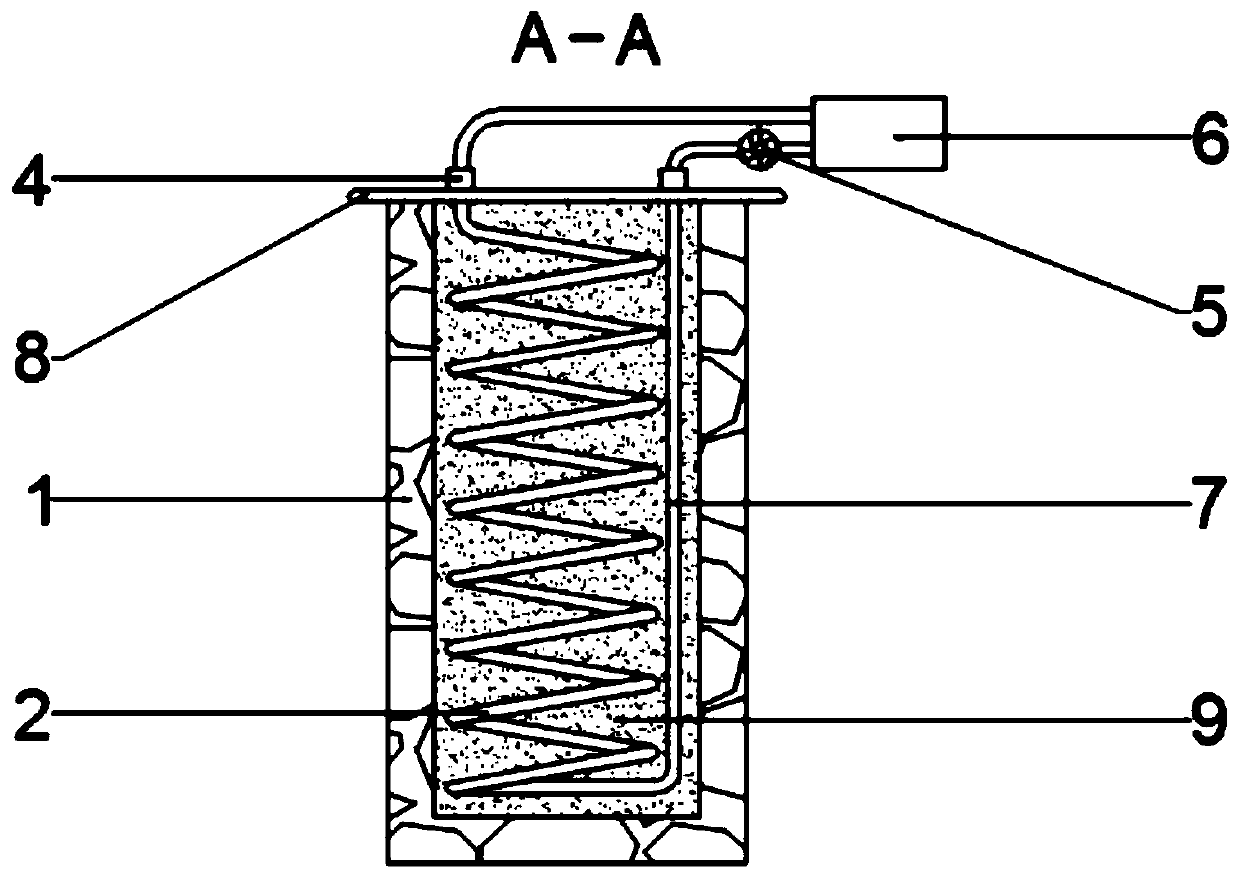

[0017] combine figure 1 and figure 2 , the graphene-modified energy pile includes a columnar pile body 1, a hole is opened at the center of the pile body 1, a spiral tubular heat transfer tube 2 is arranged in the hole inside the pile body 1, and the bottom of the heat transfer tube 2 is connected with The return pipe 7, the inside of the pile body 1 and the space between the heat transfer pipe 2 and the return pipe 7 are filled with fillers 9, the middle sections of the heat transfer pipe 2 and the return pipe 7 are bound on the steel cage 3, the heat transfer pipe 2 and the return pipe 7 The tube 7 is filled with thermal fluid, the top of the pile body 1 is sealed with a pile cap 8, the heat transfer tube 2 and the return tube 7 are vertically extended outside the pile cap 8, and the heat transfer tube 2 and the return tube 7 are located at the external port of the pile cap 8 Both communicate with the heat collector 6 through the connecting pipe 4 , and the return pipe 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com