Sodium silicate-molten binary nitrate compounded heat-transfer heat-storage medium and its preparation method and use

A heat storage medium and water glass technology, applied in chemical instruments and methods, heat exchange materials, sustainable manufacturing/processing, etc., can solve the problems of increased corrosion, no water glass, low working temperature, etc. Achieve the requirements of reduced size and energy, good heat absorption and heat storage capacity, and wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

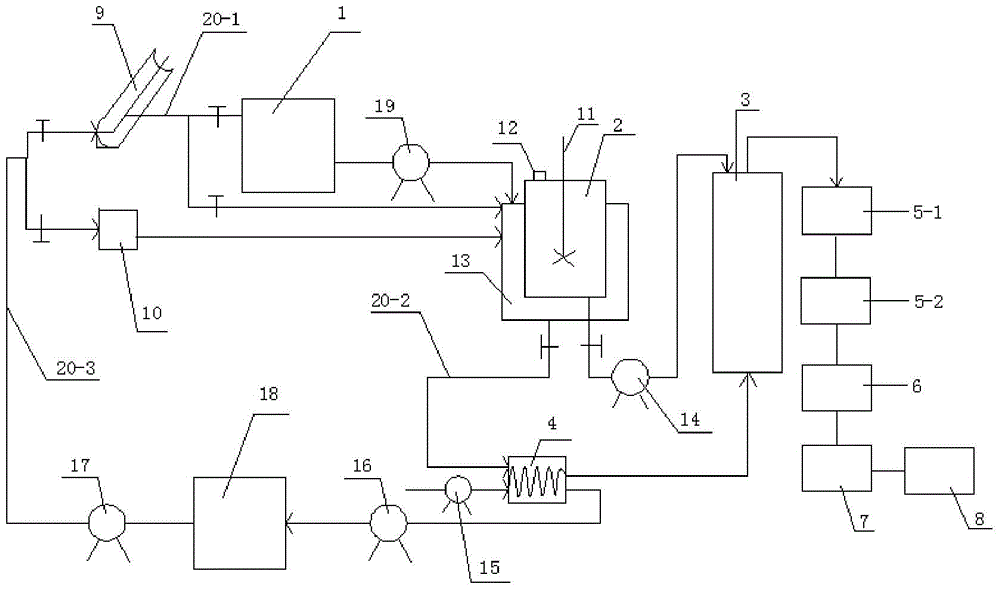

Method used

Image

Examples

Embodiment 1

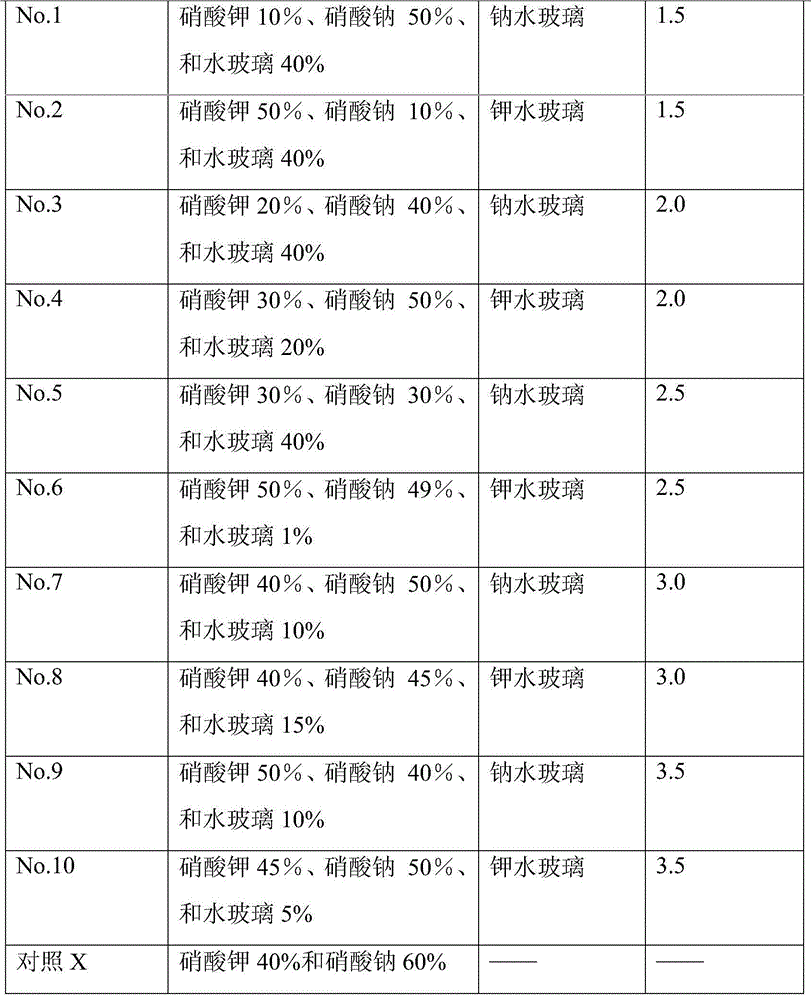

[0057] Embodiment 1, the preparation method of water glass composite binary nitric acid molten salt heat transfer heat storage medium of the present invention

[0058] Materials used: sodium silicate and potassium silicate, all purchased from Dali Zhongfashui Glass Factory, Nanhai District, Foshan City;

[0059] Potassium nitrate, sodium nitrate, industrial grade, can be purchased from general chemical companies.

[0060] 1. Preparation method:

[0061] The preparation method of water glass composite binary nitric acid molten salt heat transfer heat storage medium of the present invention has two kinds of options:

[0062] Method I, the preparation steps of water glass composite binary nitric acid molten salt heat transfer heat storage medium of the present invention are as follows:

[0063] Mix potassium nitrate, sodium nitrate and water glass according to the mass percentage content of each component and stir evenly, statically heat to about 80°C-100°C above the phase tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com