Novel phase change heat storage heat exchanger and working method

A heat storage heat exchanger and phase change heat storage technology, which is applied in the direction of indirect heat exchangers, heat exchanger types, heat storage equipment, etc., can solve the problem that heat storage bodies cannot transfer heat to each other, heat storage time prolongs, and effect time Long and other problems, to achieve good heat storage effect, improve stability, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

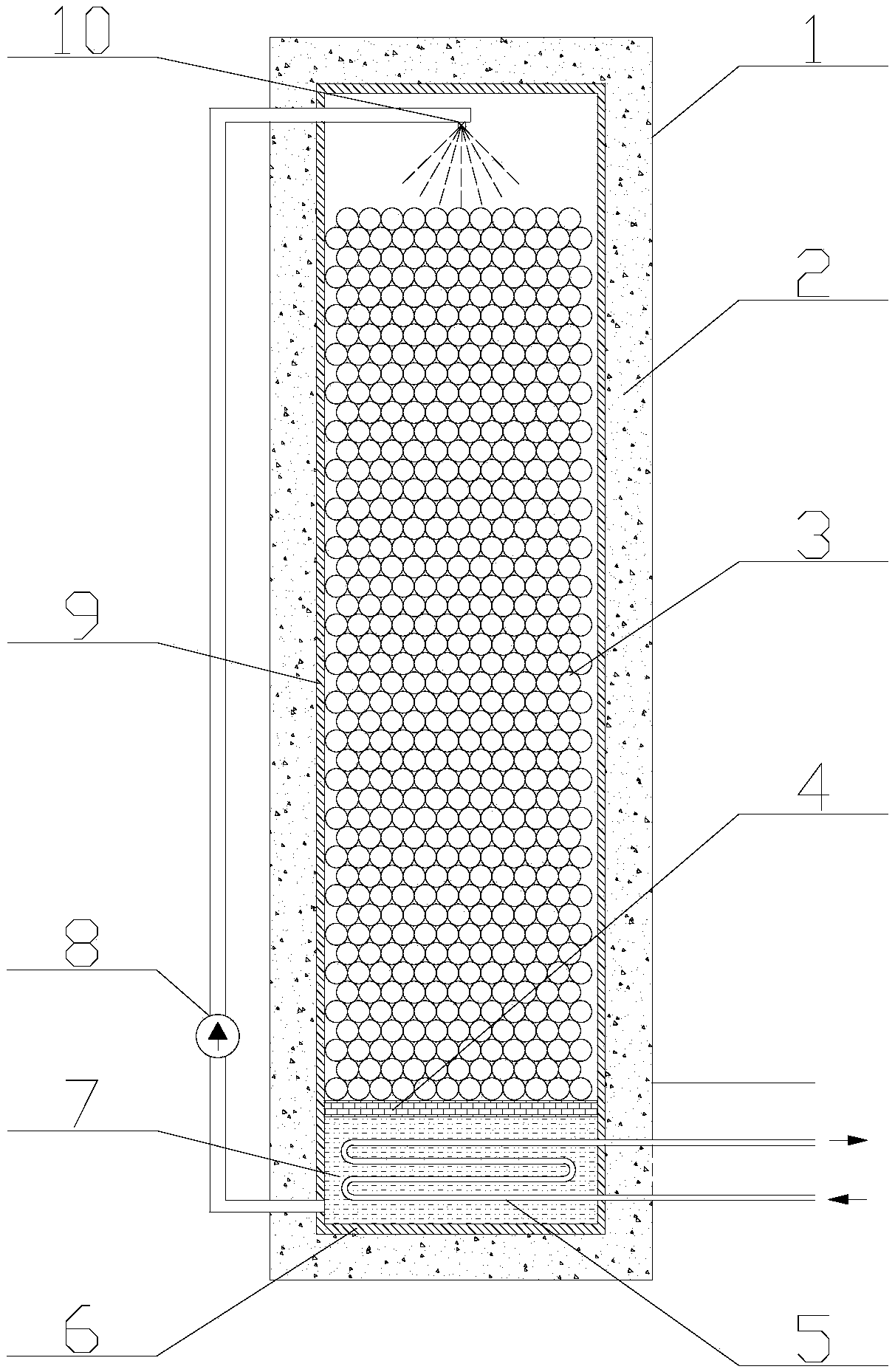

[0032] In some embodiments, a novel heat exchange tube type phase change heat storage heat exchange device is disclosed, such as figure 1 As shown, it includes a heat storage heat exchanger shell 1 , an insulation layer 2 , an adsorption heat storage material 3 , an orifice plate 4 , a heat exchange tube 5 , a heat exchange medium 7 , a heat exchange medium circulation pump 8 and an atomizing nozzle 10 .

[0033] The heat storage heat exchanger housing 1 is a cuboid or cylinder, made of pressure-resistant materials, such as cast iron or stainless steel, and an insulating layer 2 is arranged inside. The thermal insulation layer 2 is made of materials with thermal insulation and waterproof functions, and foam materials, such as polyurethane foam materials, can be used.

[0034] The inside of the heat storage heat exchanger casing 1 is in a vacuum state.

[0035] The heat storage heat exchanger housing 1 is divided into upper and lower parts. The heat storage medium box 9 is arr...

Embodiment 2

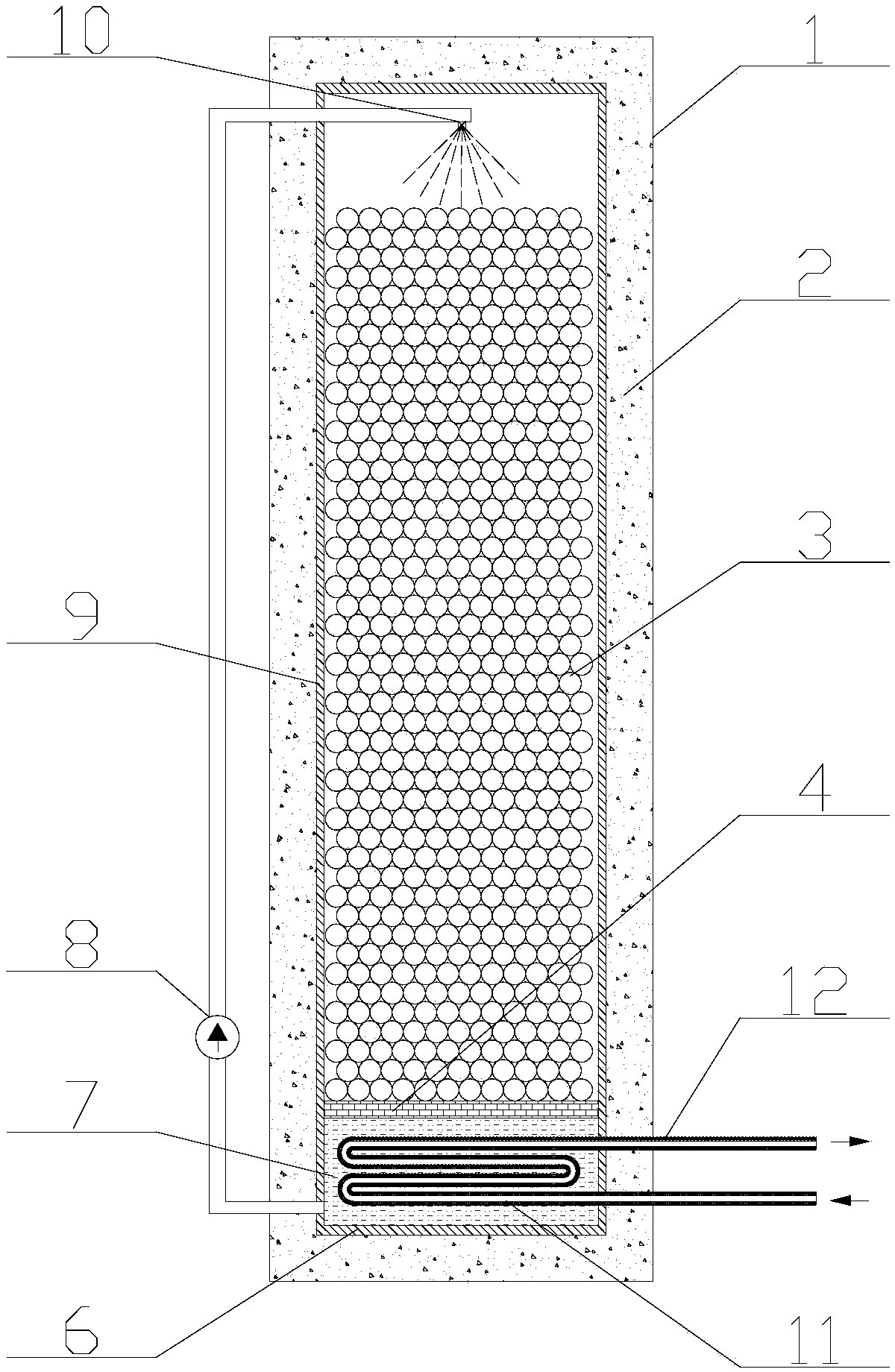

[0047] In some embodiments, a novel heat exchange tube type phase change heat storage heat exchange device is disclosed, such as figure 2 As shown, it includes: heat storage heat exchanger shell 1, insulation layer 2, adsorption heat storage material 3, orifice plate 4, heat exchange medium 7, heat exchange medium circulation pump 8, atomizing nozzle 10 and heat pipe 11.

[0048] The heat storage heat exchanger housing 1 is a cuboid or cylinder, made of pressure-resistant materials, such as cast iron or stainless steel, and an insulating layer 2 is arranged inside. The thermal insulation layer 2 is made of materials with thermal insulation and waterproof functions, and foam materials, such as polyurethane foam materials, can be used.

[0049] The inside of the heat storage heat exchanger housing 1 is in a certain negative pressure state.

[0050] The heat storage heat exchanger shell 1 is divided into upper and lower parts, with a heat storage medium box 9 on the upper side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com