Dry mixing waterproof mortar with high crack resistance

A waterproof mortar and high crack resistance technology, which is applied in the field of building materials, can solve problems that affect project quality and normal use, large shrinkage and cracking, and low bond strength, and achieve good compressive strength, improved bonding, and increased toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

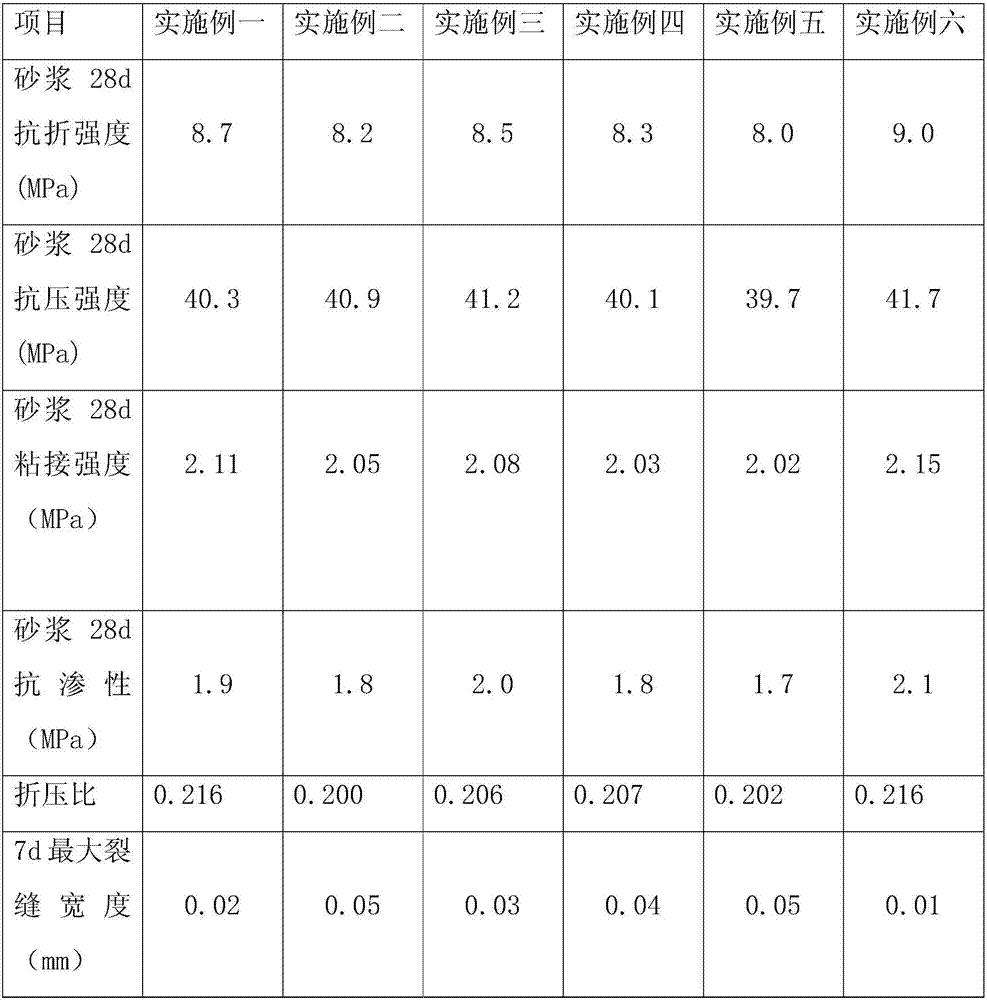

Examples

preparation example Construction

[0021] In this embodiment, the method for preparing the modified loofah fiber includes the following steps:

[0022] (1) Preparation of the solution for modification, including preparation of alkaline mixed solution A and acidic mixed solution B, where:

[0023] The preparation method of the alkaline mixed solution A is as follows: 16.0 parts of NaOH and 1.5 parts of urea are placed in 82.5 parts of deionized water by weight, and the mixture is stirred and dissolved;

[0024] The preparation method of the acidic mixed solution B is: take 30 parts by weight of H 2 SO 4 , 50 parts Na 2 SO 4 And 60 parts of ZnSO 4 Put it in 860 parts of deionized water and stir to dissolve;

[0025] (2) Preparation of modified loofah fiber: After cutting the loofah into small pieces, tear the loofah into a single piece of loofah silk, then put the loofah silk in the alkaline mixed solution A, heat up to 100 ℃, boil for 25 minutes, and then take out the loofah silk Place it in acidic mixed solution B, soa...

Embodiment 1

[0033] According to the high crack resistance dry-mixed waterproof mortar provided in this embodiment, the raw materials of the dry-mixed waterproof mortar include the following components by weight: 410 parts of cement, 1430 parts of machine-made sand, 75 parts of fly ash (600-800 mesh), Acrylic latex powder (0.5-8μm) 2 parts, EVA latex powder (0.5-8μm) 4 parts, styrene butadiene rubber latex 8 parts, modified loofah fiber 120 parts, ramie fiber (monofilament length 9-12mm) 100 parts, bamboo charcoal Fiber (monofilament length is 9-12mm) 55 parts, seaweed powder (600-800 mesh) 90 parts, silicone defoamer 1.0 part, water 350 parts; the fineness modulus of the machine-made sand is 1.8, MB is 1.4. The stone powder content is 10%.

[0034] In this embodiment, the method for preparing dry-mixed waterproof mortar with high crack resistance includes the following steps: uniformly mixing cement, machine-made sand, fly ash, seaweed powder, acrylic latex powder and EVA latex powder by wei...

Embodiment 2

[0041] In the high-crack resistance dry-mixed waterproof mortar provided in this embodiment, the raw materials of the dry-mixed waterproof mortar include the following components by weight: 400 parts of cement, 1450 parts of machine-made sand, 75 parts of fly ash (600-800 mesh), Acrylic latex powder (0.5-8μm) 0.8 parts, EVA latex powder (0.5-8μm) 0.8 parts, styrene butadiene latex 12 parts, modified loofah fiber 120 parts, ramie fiber (monofilament length 9-12mm) 100 parts, bamboo charcoal Fiber (monofilament length is 9-12mm) 50 parts, seaweed powder (600-800 mesh) 100 parts, silicone antifoaming agent 1.0 part, water 350 parts; the fineness modulus of the machine-made sand is 2.2, MB is 1.0, the stone powder content is 7%.

[0042] In this embodiment, the method for preparing the high crack resistance dry-mixed waterproof mortar and the preparation method of the modified loofah fiber are the same as those in the first embodiment, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com