Wind turbine yawing system, wind turbine and yawing process

a wind turbine and yawing technology, applied in the direction of liquid fuel engines, vessel construction, marine propulsion, etc., can solve the problems of deterioration of gear teeth, insufficient retention capacity of braking systems, and costly repairs, and achieve the effect of greater braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] One of the objectives of the invention is to provide a yawing system having elements which can be easily replaced in repair.

[0015] Another objective of the invention is to obtain a braking system with more capacity than the known systems, but which is compact, i.e. it occupies little space in the upper part of the tower.

[0016] Another objective of the invention is to obtain a braking system which can be easily adapted during the assembly to places with different wind conditions.

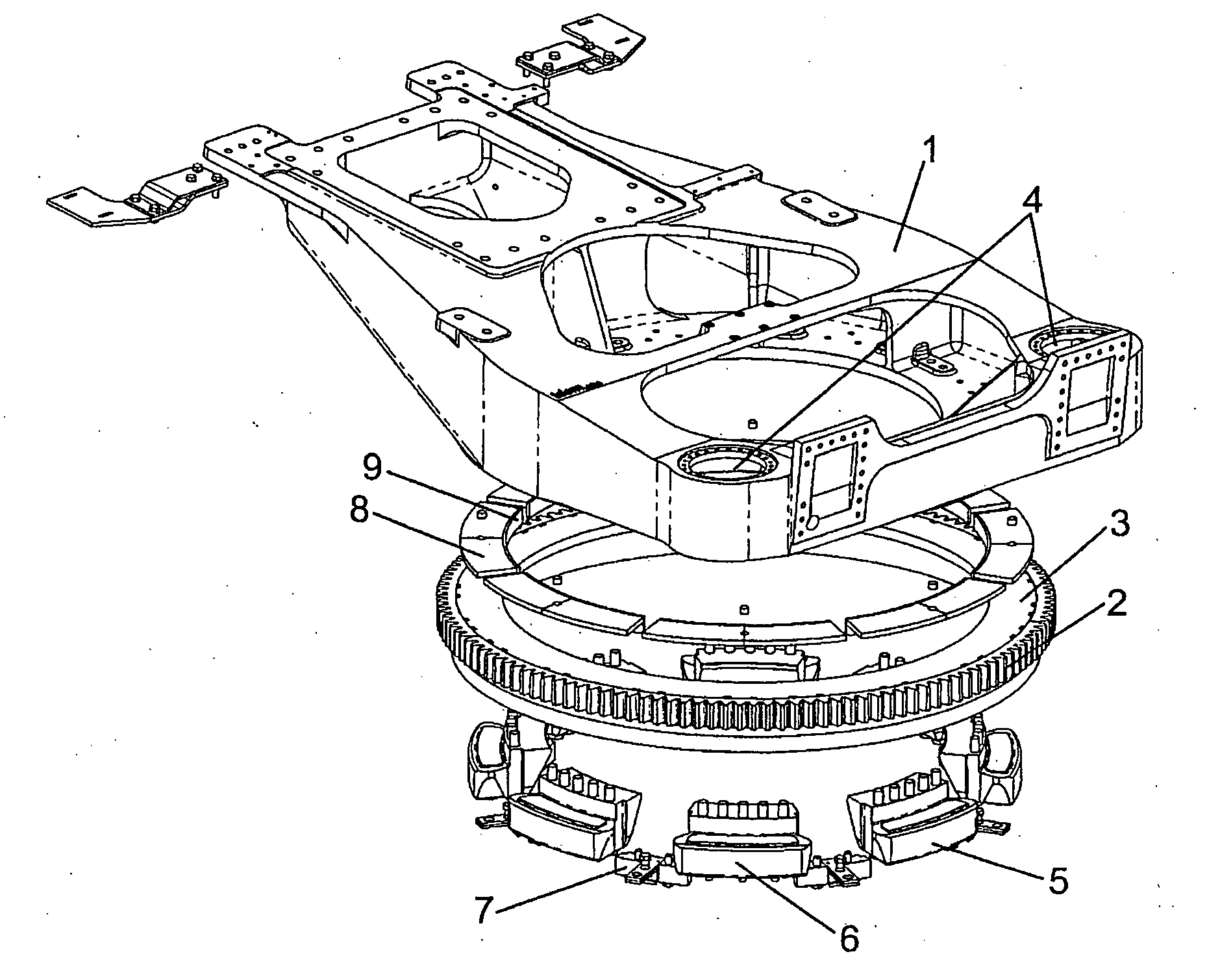

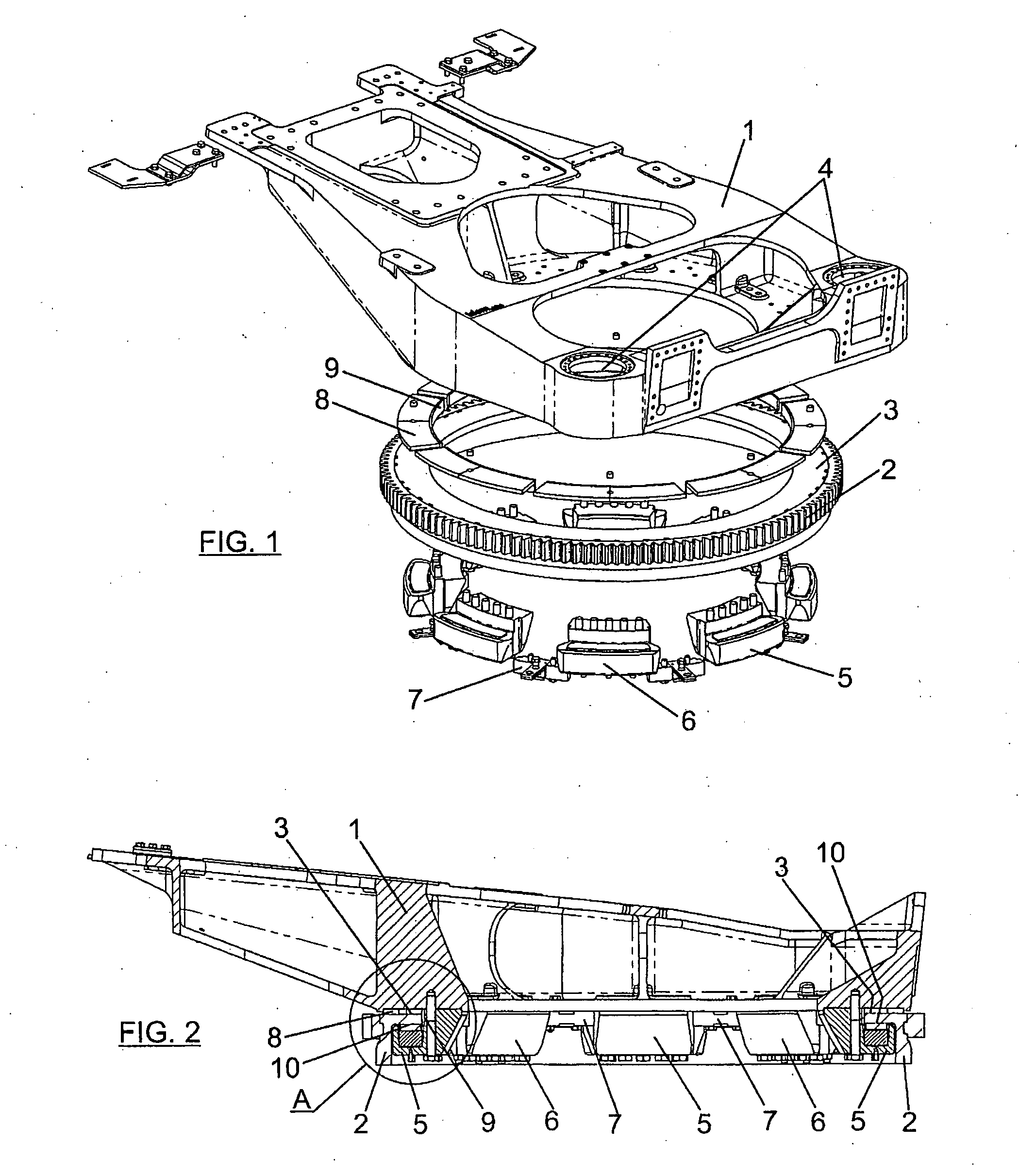

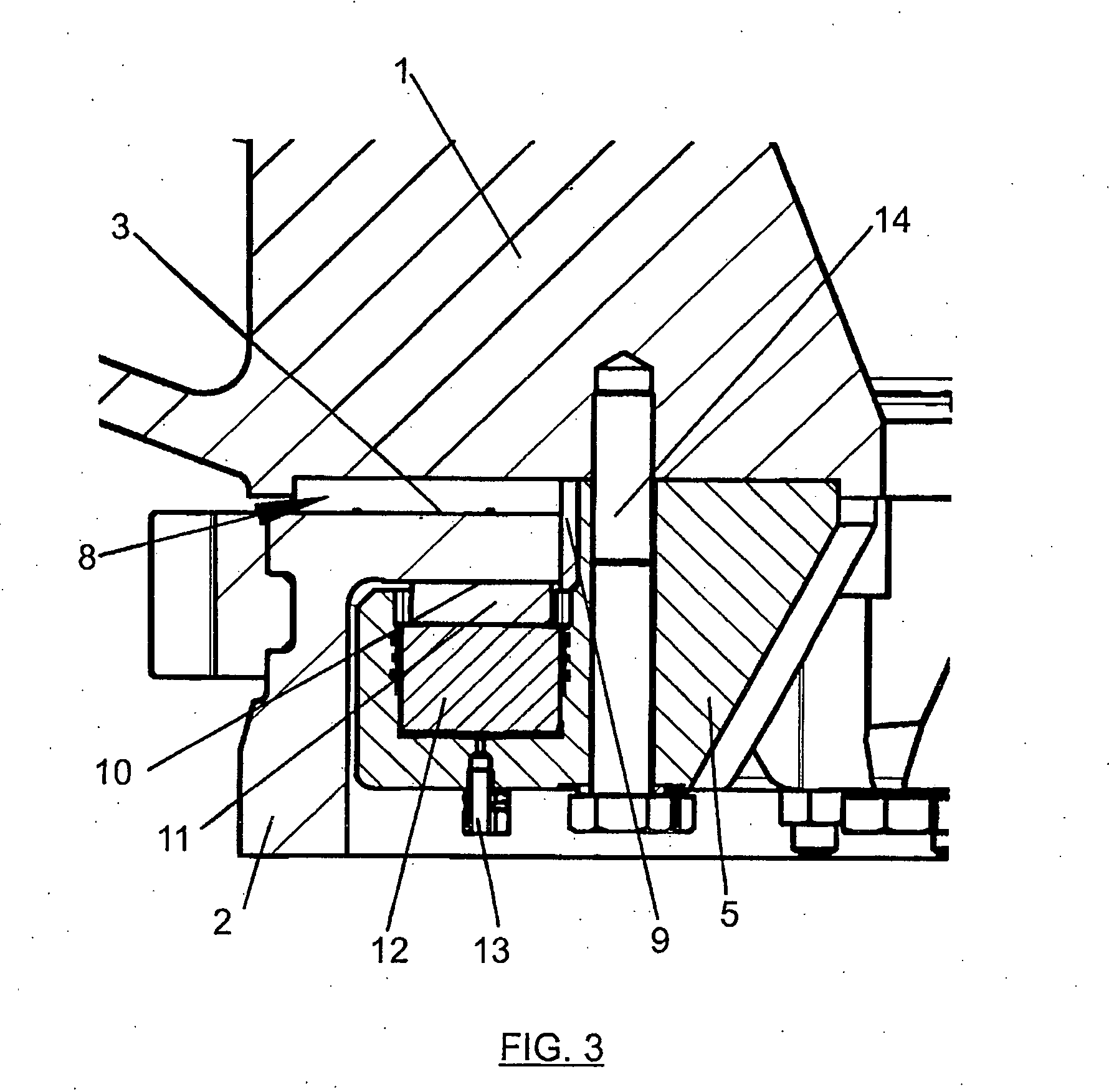

[0017] The yawing system of the wind turbine comprises, as in other known systems, a yawing system joining a tower fixed to the ground with a frame supporting the generator (and forming part of that which is called the nacelle of the wind turbine). This yawing system allows the orientation of the frame with respect to the tower according to the direction of the wind, and comprises at least the following elements: [0018] a gear ring configured to be fixed to said tower, the gear ring having a sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com