Pedal decoupling type electro-hydraulic composite braking system for integrated pedal displacement measurement

A displacement measurement, electro-hydraulic composite technology, applied in electric braking systems, brakes, electric vehicles, etc., can solve the problems of inconvenient braking system modification, extremely high manufacturing process requirements, complex control logic, etc., to achieve scalability and Good applicability, convenient cost and difficulty, precise control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

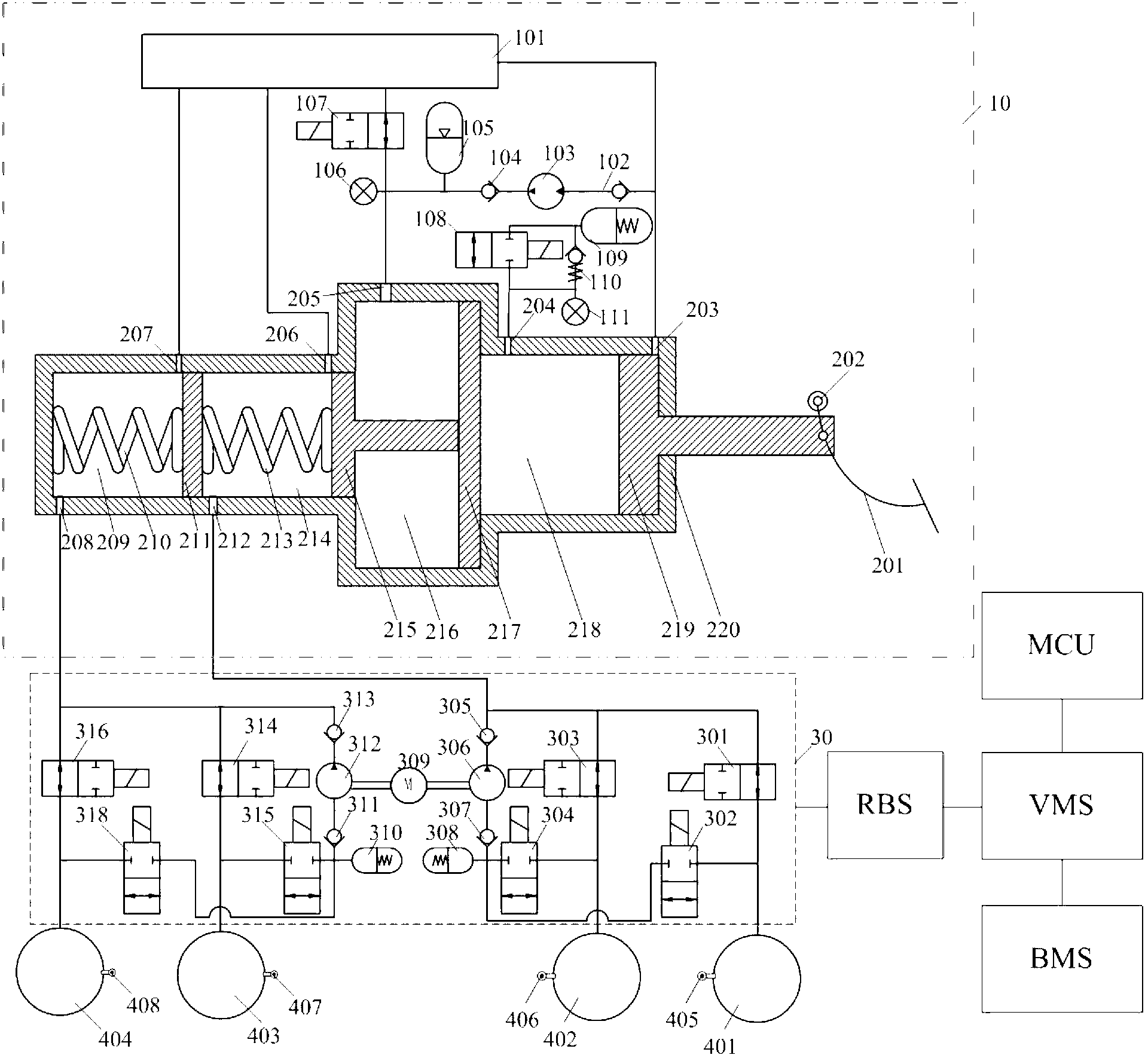

[0051] A pedal decoupled electro-hydraulic brake system with integrated pedal displacement measurement, its structure is as follows figure 1 As shown, it includes compound brake control unit RBS, hydraulic brake subsystem and motor feedback brake subsystem. The motor feedback subsystem is composed of vehicle controller VMS, motor controller MCU and battery management system BMS. The hydraulic brake subsystem The system is composed of an integrated brake master cylinder assembly 10 and a hydraulic control unit 30, and the integrated brake master cylinder assembly 10 is composed of an integrated brake master cylinder and a high-pressure oil source.

[0052] The basic working principle of the pedal decoupling electro-hydraulic composite braking system integrated with pedal displacement measurement is as follows: the composite braking control unit RBS collects the pressure sensor 111 to obtain the driver's braking operation intention, and calculates the driver's required braking fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com