Method for preparing nanoparticle-modified friction material

A nanoparticle modification and friction material technology, which is applied to friction linings, mechanical equipment, etc., can solve the problems of reduced friction performance, weak combination of resins, nanoparticles and reinforcing fibers, and uneven mixing of raw materials, so as to improve thermal fading , Improve heat recovery performance, improve friction performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

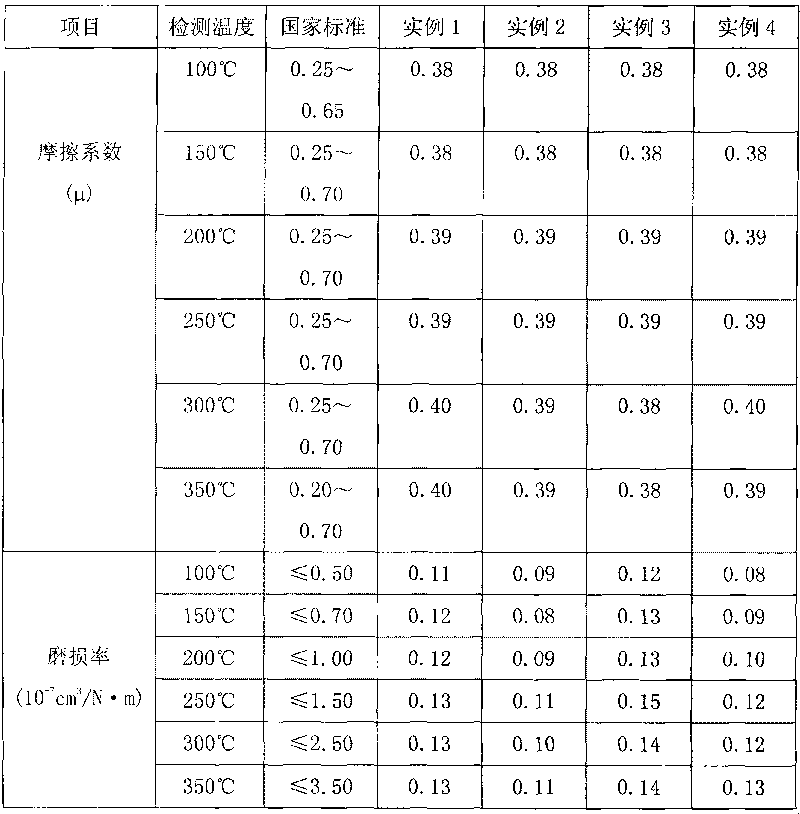

Examples

example 1

[0023] Weigh 5 parts of phenolic resin and 0.05 parts of hexamethylenetetramine, dissolve them in the mixed solution of denatured alcohol and xylene, add 0.5 parts of silane coupling agent at the same time, stir well to obtain resin solution; weigh 2 parts of nano-oxidized Put aluminum and 1 part of nano-silica into industrial alcohol, add 0.05 parts of polyethylene glycol at the same time, stir well, pour it into the resin solution, mix and stir evenly; then add 15 parts of aramid fiber and 5 After stirring, add 1.5 parts of molybdenum disulfide, 4 parts of graphite, 16 parts of barite, 5 parts of wollastonite, and 4 parts of tire powder. The above composite materials were mixed and stirred evenly, and then dried in an oven at 90° C. for 24 hours to obtain a friction material.

example 2

[0025] Weigh 10 parts of boron-modified phenolic resin and 0.15 parts of urotropine, dissolve them in the mixed solution of denatured alcohol and acetone, add 0.8 parts of sodium dodecylbenzene sulfonate at the same time, and stir to obtain a resin solution; weigh Put 3 parts of nano-calcium carbonate and 2 parts of nano-silicon carbide into the acetone solution, add 0.1 part of oleic acid at the same time, stir well, pour it into the resin solution, mix and stir evenly; then add 5 parts of steel fiber and 8 parts to the above mixed solution. 3.5 parts of molybdenum disulfide, 7 parts of graphite, 30 parts of barite, 10 parts of wollastonite, and 10 parts of tire powder are added after stirring. The above composite materials were mixed and stirred evenly, and then dried in an oven at 120° C. for 8 hours to obtain a friction material.

example 3

[0027] Weigh 15 parts of melamine-modified phenolic resin, 0.5 part of hexamethylenetetramine and 0.2 part of urotropine, dissolve them in a mixed solution of denatured alcohol and ethyl acetate, add 0.1 part of sodium polyacrylate and 0.2 parts of ten Dialkyl sodium sulfate, stir well to get resin solution; weigh 5 parts of nano wollastonite and 2 parts of nano calcium carbonate into industrial alcohol, add 0.1 part of polyethylene glycol at the same time, stir well and pour into resin solution , mix and stir evenly; then add 10 parts of steel fiber and 20 parts of pitch carbon fiber to the above mixed solution, stir evenly and dry in an oven at 100° C. for 12 hours. Add 5 parts of molybdenum disulfide, 15 parts of graphite, 30 parts of barite, 10 parts of alumina, and 10 parts of tire powder to the above dried composite material, mix and stir evenly to obtain a friction material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com