Hybrid electrical vehicle (HEV)/electrical vehicle (EV) regeneration brake pressure coordinate control system based on antilock brake system (ABS) hardware

A technology of coordinated control system and regenerative braking, applied in electric braking systems, brakes, brake transmissions, etc., can solve the problems of inability to achieve regenerative braking force and hydraulic braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

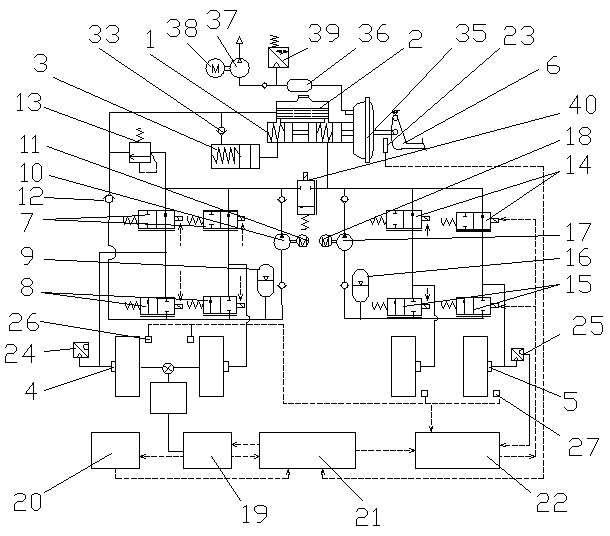

[0025] Embodiment one, such as figure 1 As shown, the HEV / EV regenerative braking pressure coordinated control system based on ABS hardware in this embodiment includes a hydraulic braking subsystem, a motor regenerative braking subsystem, and a hydraulic braking subsystem and a motor regenerative braking subsystem. control system,

[0026] The hydraulic braking subsystem includes a vacuum booster system, a brake master cylinder 1, an oil storage tank 2, a stroke simulator 3, a front wheel ABS pressure regulating system, a front wheel brake wheel cylinder 4, a rear wheel ABS pressure regulating system and The rear wheel brake wheel cylinder 5, the power input end of the vacuum booster system is connected with the automobile brake pedal 6, the power output end of the vacuum booster system is connected with the power input end of the brake master cylinder 1, and the brake master cylinder 1 includes a working chamber Ⅰ and working chamber II, the oil storage tank 2 communicates w...

Embodiment 2

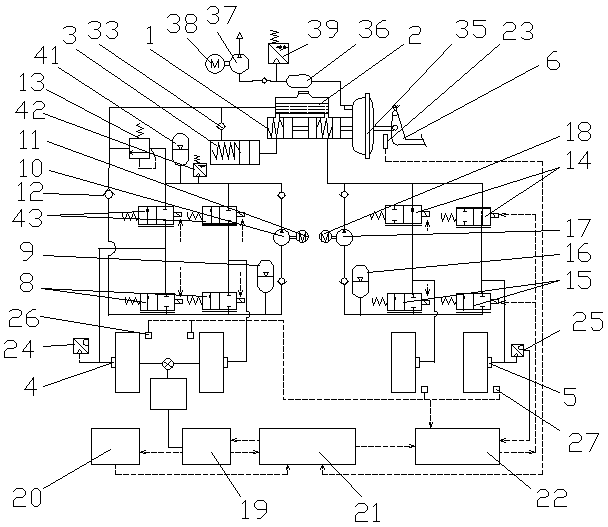

[0037] Embodiment two: if figure 2 As shown, the difference between this embodiment and Embodiment 1 is: 1. The high-speed switch valve group I includes a normally closed high-speed switch valve I8 and a normally closed high-speed switch valve III43, and the oil storage tank 2 passes through the valve connected with the check valve I12. The oil pipe I is respectively connected with the inlet of the normally closed high-speed switch valve I8 and the low-pressure accumulator I9, the outlet of the low-pressure accumulator I9 is connected with the inlet of the oil return pump I10, and the outlet of the oil return pump I10 is connected with the inlet of the normally closed high-speed switch valve III43 , the outlet of the oil return pump I10 is also communicated with the oil storage tank 2 through the overflow valve 13, and the outlet of the normally closed high-speed switch valve III43 is respectively communicated with the normally closed high-speed switch valve I8 and the inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com