Composite braking system

A compound brake and brake pedal technology, which is applied in electric brake systems, electric vehicles, transportation and packaging, etc., can solve the problems of brake master cylinder pressure fluctuations, influence on pedal feeling, brake pedal vibration, etc., and achieve processing Ease of manufacture, improved brake feel, good brake pedal feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

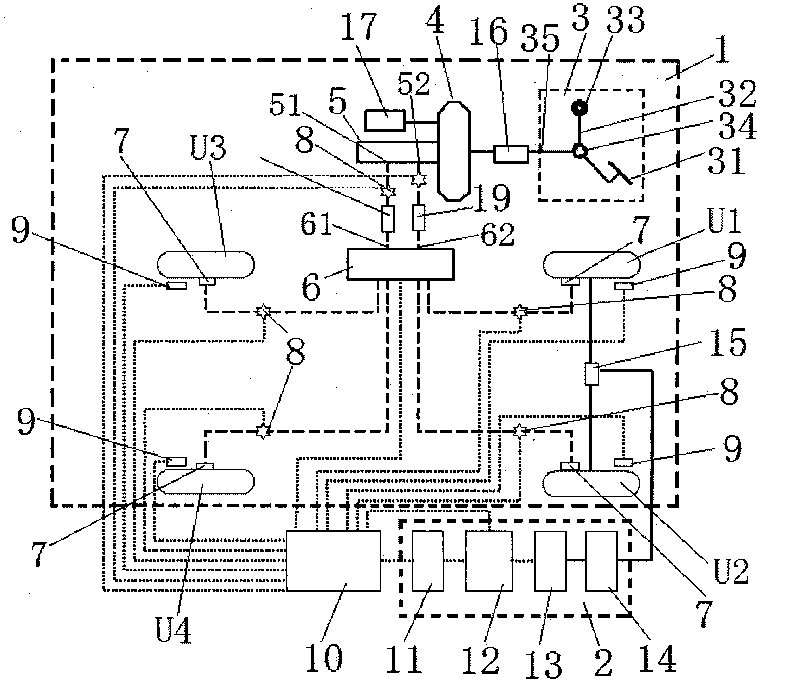

[0018] In order to obtain better brake pedal feeling while realizing serial braking energy recovery, the present invention adds a shock absorber, a vacuum supply module and two main valves on the basis of the existing composite braking system.

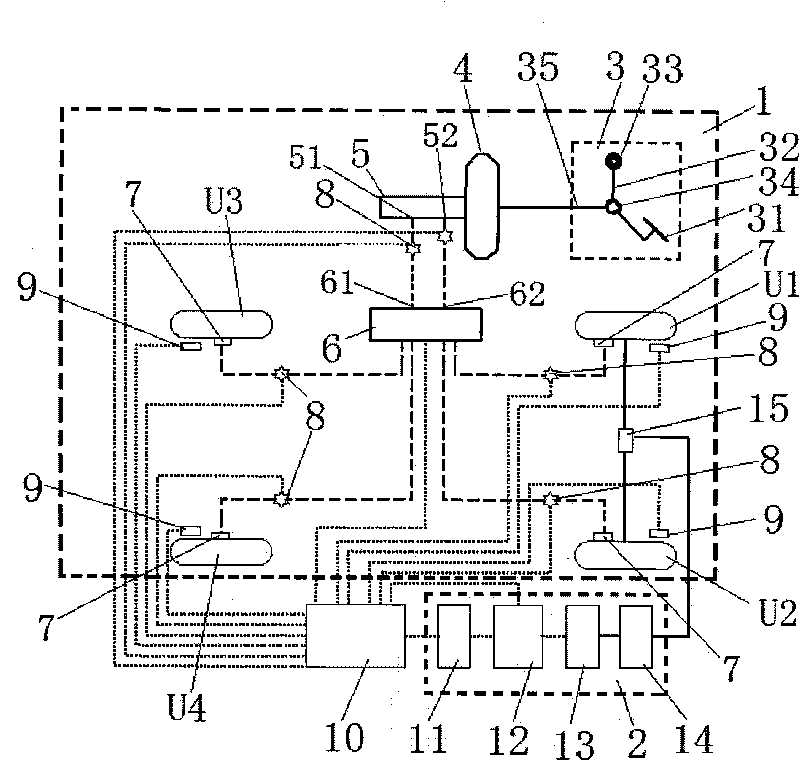

[0019] Such as figure 1 As shown, the existing composite braking system includes a hydraulic braking system 1 and a motor braking system 2. The motor braking system 2 converts a part of vehicle kinetic energy into electric energy and stores it in the battery through electric power generation. The insufficient braking force is caused by Hydraulic braking system 1 is provided.

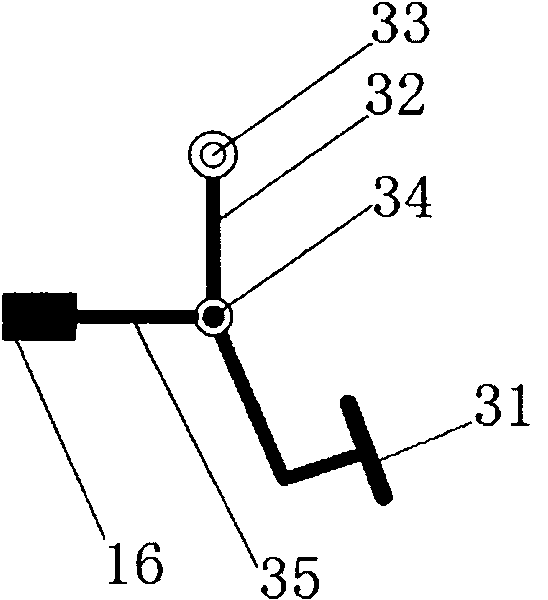

[0020] Among them, the existing hydraulic braking system 1 includes a brake assembly 3, a vacuum booster 4, a brake master cylinder 5, a hydraulic adjustment module 6, four brake wheel cylinders 7, six pressure sensors 8, four Wheel sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com